Method of preparing phenolic resin through liquefaction of lignin by using ionic liquid

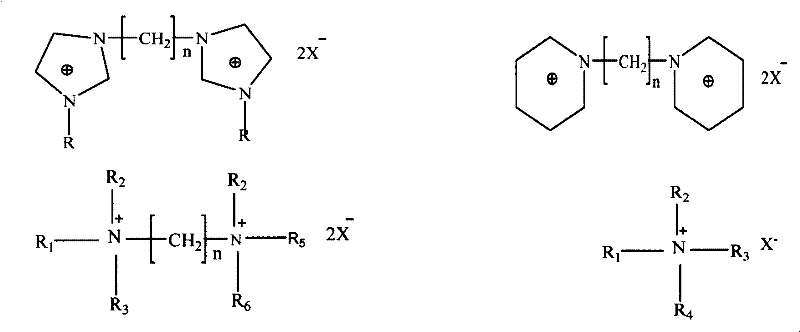

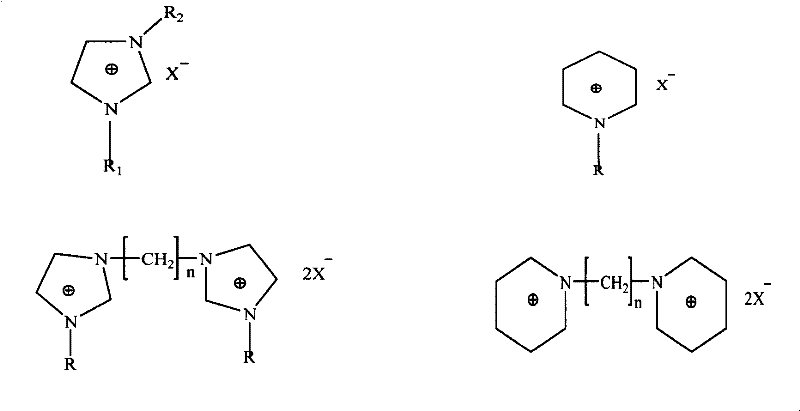

A technology of ionic liquid and lignin, which is applied in the field of adhesives, can solve the problems of high energy consumption, large steric hindrance of substituents, and difficult operation, and achieve the effects of reducing the liquefaction residue rate, less corrosive equipment, and mild liquefaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 10g[bmin]Cl and 0.5g straw into a three-neck flask, 2 Heat to 100 DEG C in a stirring oil bath, react for a period of time, when the color of the solution turns purple brown from colorless, stop the reaction, add 0.5g formaldehyde and 3g sodium hydroxide (adding with 30% concentration) after cooling, Under normal pressure, raise the temperature to 40°C and react for 5 minutes, then raise the temperature to 80°C and react for 3 hours, measure the viscosity (viscosity is controlled at about 3-6s) by the reverse bubble method, and stop heating when it meets the adhesive requirements to obtain the adhesive.

Embodiment 2

[0030] 5g 3,3'-ethyl-1,2-bis(N-methylimidazolium) chloride salt and 0.5g straw were added in the three-necked flask, under N 2 Heat to 80 ℃ in a stirring oil bath, react for a period of time, when the color of the solution changes from colorless to purple brown, stop the reaction, add 1.5g formaldehyde and 2g sodium hydroxide (adding with 40% concentration) after cooling, Under normal pressure, raise the temperature to 50°C and react for 10 minutes, then raise the temperature to 90°C and react for 2 hours, measure the viscosity (viscosity is controlled at about 3-6s) by the reverse bubble method, and stop heating when it meets the adhesive requirements to obtain the adhesive.

Embodiment 3

[0032] Add 10g NMPCl and 0.5g straw into the three-neck flask, 2 Heat to 120 DEG C in a stirring oil bath, react for a period of time, when the color of the solution turns purple-brown from colorless, stop the reaction, add 0.5g formaldehyde and 3g sodium hydroxide (adding with 30% concentration) after cooling, in Under normal pressure, raise the temperature to 40°C and react for 5 minutes, then raise the temperature to 80°C and react for 3 hours, measure the viscosity (viscosity is controlled at about 3-6s) by the reverse bubble method, and stop heating when it meets the adhesive requirements to obtain the adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com