High pulse repetition frequency mode-locking optical fiber laser

A fiber laser, high repetition frequency technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of narrow tuning range of SESAMs, affecting saturable absorption, complex production and packaging processes, etc., to achieve small size , simple structure, and high damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment, but should not limit protection scope of the present invention with this.

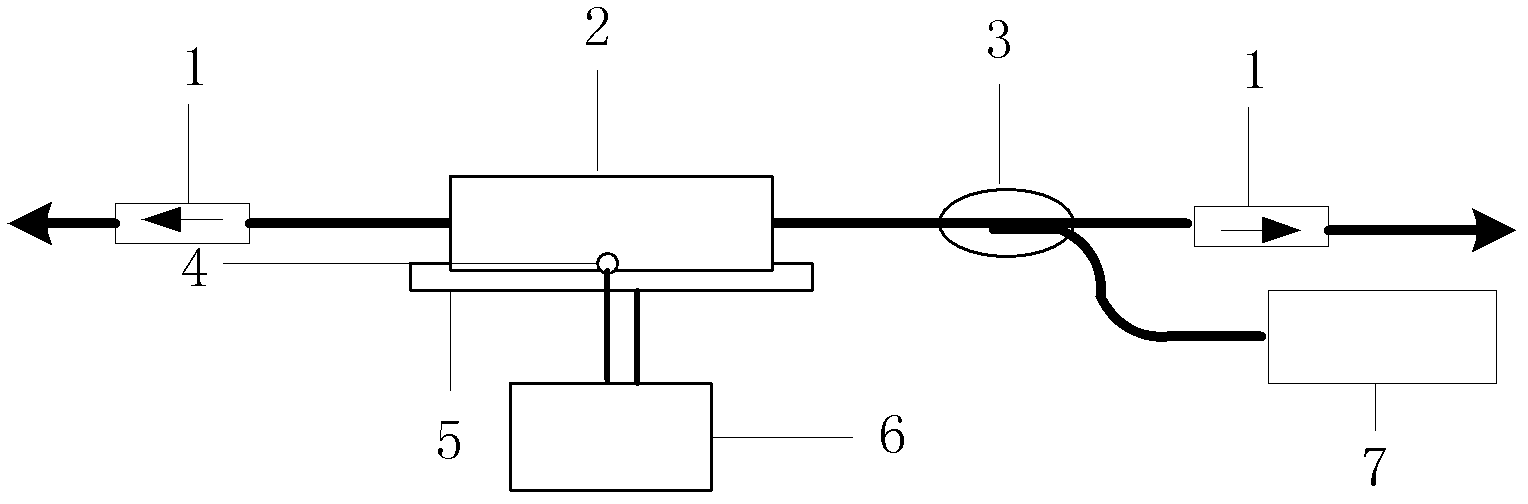

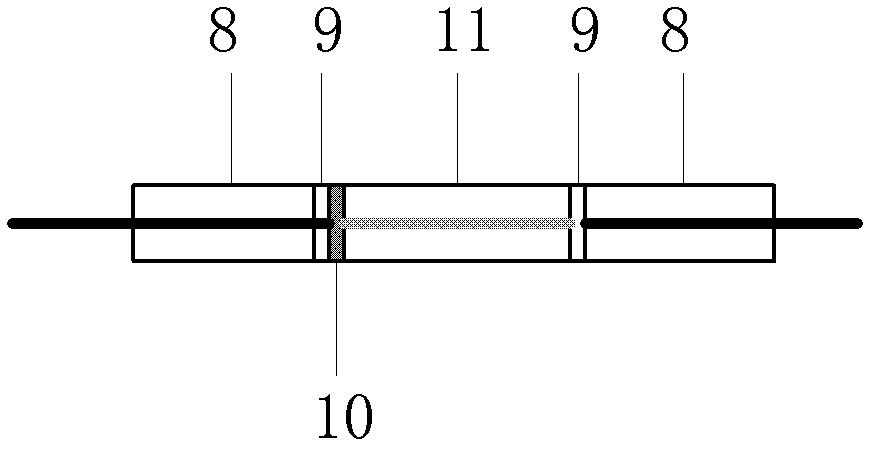

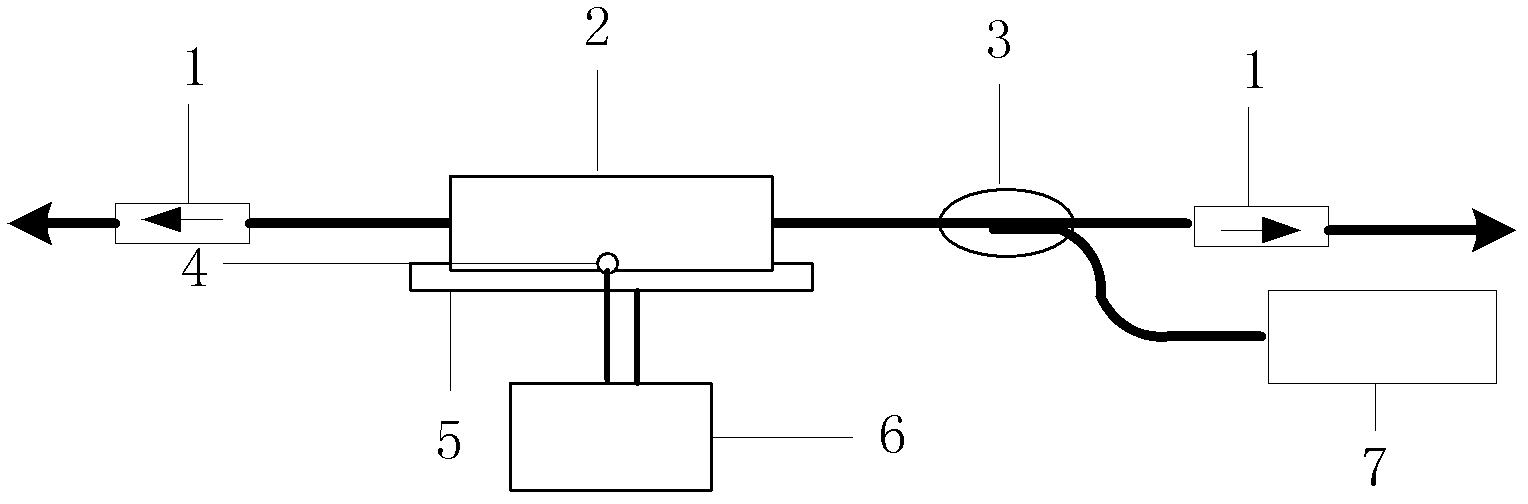

[0029] The structure of the high repetition rate mode-locked fiber laser of the present invention is as follows figure 1 shown. It can be seen from the figure that the high repetition rate mode-locked fiber laser of the present invention includes a pump laser 7 and a laser resonator 2, the laser resonator 2 is an FP cavity structure, and the gain medium 11 and the mode-locking element 10 are located between two optical fibers. Between the end faces of the parts 8, the end faces of the optical fiber connectors are coated with a dichroic film 9, the gain fiber 11 is a phosphate fiber doped with rare earth ions, the mode-locking element 10 is graphene, and the laser resonance One end of the cavity 2 is output through the laser isolator 1, the other end of the laser resonator 2 is connected to an output end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com