Preparation method for ultrahigh molecular weight polyethylene microporous membrane

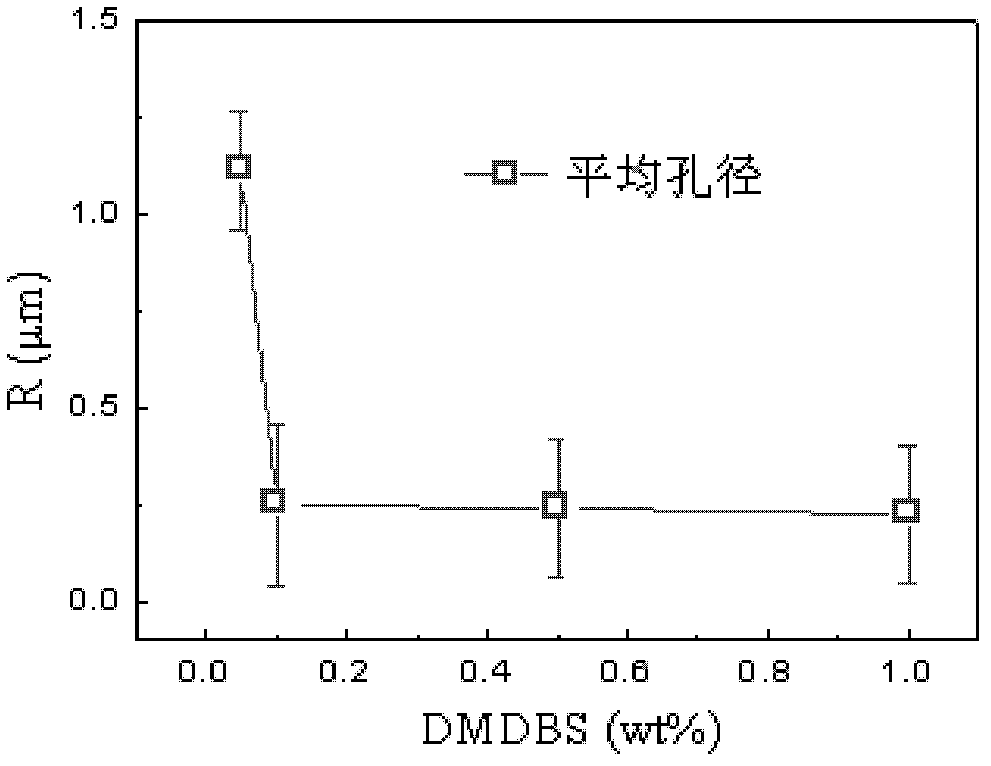

A polyethylene microporous membrane and ultra-high molecular weight technology, applied in the field of membrane separation, can solve problems such as difficulty in obtaining pore structure, uneven pore size distribution of microporous membranes, etc., to prevent agglomeration, speed up the crystallization process, and small pore size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Melt and mix the ultra-high molecular weight polyethylene of 10% weight fraction, the liquid paraffin of 89.5% weight fraction, the antioxidant dibutyltin maleate of 0.5% weight fraction by Haake torque rheometer, obtain ultra-high molecular weight Polyethylene blend. The melt mixing temperature is 160° C., the melt mixing time is 12 min, and the rotor speed is 80 rpm.

[0033](2) Then the ultra-high molecular weight polyethylene mixture is formed into a flat film on a laminator. The film thickness is controlled at 200um, the molding temperature is 160°C, and the molding time is 5min.

[0034] (3) Then use absolute ethanol to extract the liquid paraffin, wash it repeatedly with deionized water, and form a microporous membrane after drying.

[0035] (4) Finally, an oven is used to dry and anneal the microporous membrane to obtain an ultra-high molecular weight polyethylene microporous membrane. The drying temperature is 80°C, the drying time is 3 hours, the anneal...

Embodiment 2

[0037] (1) First use a flask to melt and mix 150 g of liquid paraffin and 1% by weight of DBS in an oil bath at 240° C., while stirring magnetically until a homogeneous solution is formed. After cooling the homogeneous solution, the DBS nanofiber-liquid paraffin gel can be obtained.

[0038] (2) then by Haake torque rheometer by the ultra-high molecular weight polyethylene of 10% weight fraction, the DBS nanofiber-liquid paraffin gel of 89.5% weight fraction, the antioxidant dibutyltin maleate of 0.5% weight fraction Melt mixing to obtain ultra-high molecular weight polyethylene mixture. The melt mixing temperature is 170° C., the melt mixing time is 16 min, and the rotor speed is 80 rpm.

[0039] (3) Molding the ultra-high molecular weight polyethylene mixture into a flat film. The film thickness is controlled at 200um, the pressure is 5MPa, the molding temperature is 170°C, and the molding time is 6min.

[0040] (4) Next, the liquid paraffin is extracted with absolute eth...

Embodiment 3

[0043] (1) The antioxidant dibutyltin maleate of 30% by weight of ultra-high molecular weight polyethylene, 69% by weight of liquid paraffin, and 1% by weight of Haake torque rheometer is melt-mixed to obtain ultra-high-molecular-weight polyethylene vinyl mixture. The melt mixing temperature is 170° C., the melt mixing time is 12 min, and the rotor speed is 80 rpm.

[0044] (2) Molding the ultra-high molecular weight polyethylene mixture into a flat film. The film thickness is controlled at 200um, the molding temperature is 170°C, the molding time is 5min, and the pressure is 5MPa.

[0045] (3) Next, the liquid paraffin is extracted with absolute ethanol, washed with deionized water, and dried to form a microporous membrane.

[0046] (4) Finally, an oven is used to dry and anneal the microporous membrane to obtain an ultra-high molecular weight polyethylene microporous membrane. The drying temperature is 80°C, the drying time is 3 hours, the annealing temperature is 110°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com