Carbon nano-sphere/modified titanium dioxide nano-sol composite and preparation method thereof

A technology of carbon nano-microspheres and titanium dioxide, which is applied in the direction of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc., can solve the problems that various nano-sol particles cannot be uniformly coated, and uniform coating cannot be realized, and achieve suitable Large-scale industrial production, good chemical and thermal stability, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of carbon nanosphere / modified titanium dioxide nanosol composite material, comprising:

[0034] Provide titanium dioxide nano sol and carbon nano microspheres;

[0035] Using chloroauric acid as raw material, mercaptan as surfactant, and tetraoctyl ammonium bromide as phase transfer agent, a reduction reaction occurs under the action of mercaptocarboxylic acid and sodium borohydride to obtain a modified gold nano-sol;

[0036] Dispersing the modified gold nano sol and the titanium dioxide nano sol respectively in an organic solvent and mixing them together to obtain a titanium dioxide sol modified with gold nano sol;

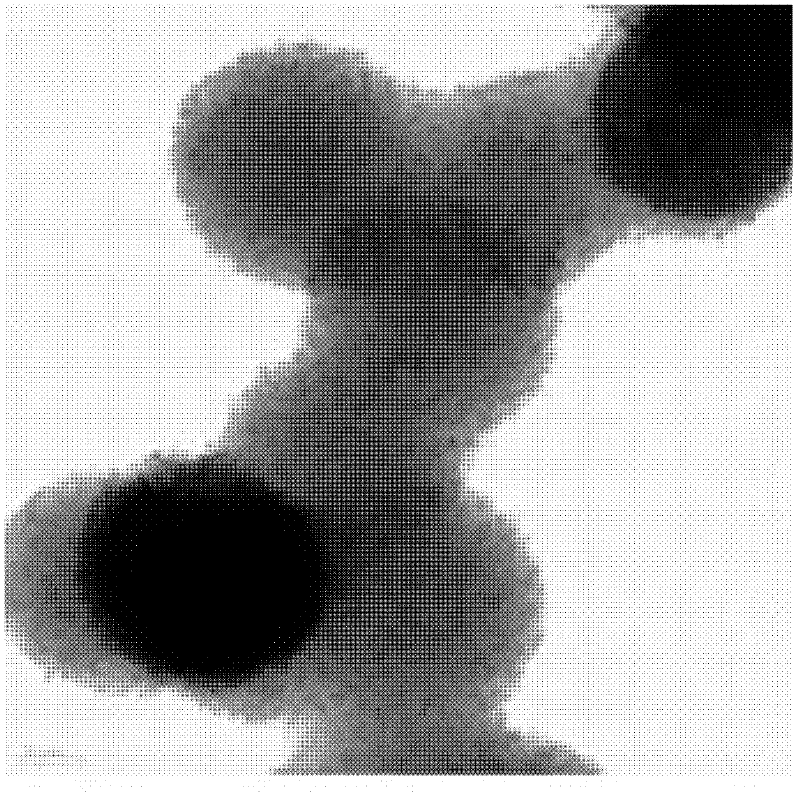

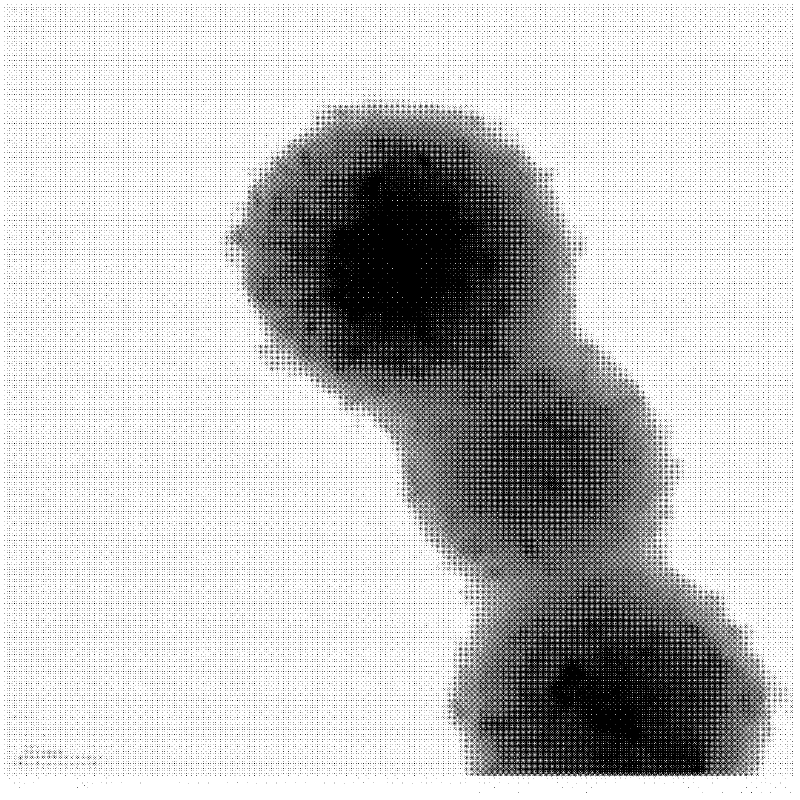

[0037] The titanium dioxide sol modified by the gold nanometer sol is dispersed in an organic solvent, mixed with the toluene solution of the carbon nanometer microspheres, and the carbon nanometer microsphere / modified titanium dioxide sol composite material is obtained after uniform stirring.

[0...

Embodiment 1

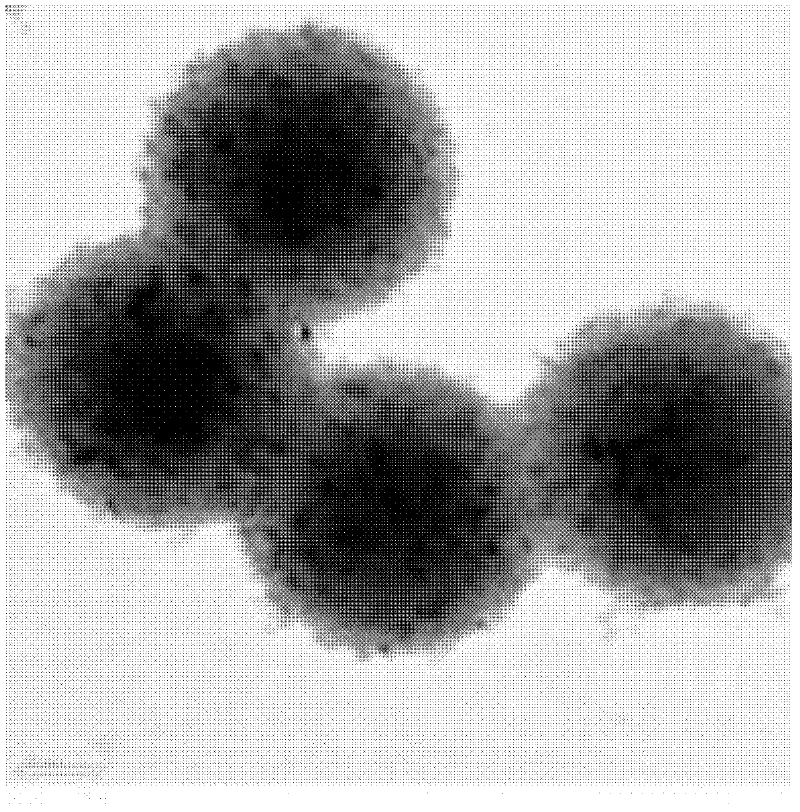

[0052] Take 3g of glucose and 30mL of pure water and mix them in a 50mL reactor, heat to 180°C and react for 10h to obtain a carbon nanosphere sol with an average particle size of 300nm, which is washed and dried.

[0053] Disperse 0.15g of TTIP and 5mL of oleic acid in toluene, dissolve 0.1mL of tert-butylamine in water, mix the toluene solution of TTIP and oleic acid with the aqueous solution of tert-butylamine in a 50mL reactor, heat to 180°C for 4h, and obtain the average Titanium dioxide nano-sol with a particle size of 4nm.

[0054] Get 0.09mmol chloroauric acid, 0.9mmol sodium borohydride, 0.18mmol TOAB, 0.09mmol DDT and 0.09mmol 3-mercaptopropionic acid, chloroauric acid is dissolved in water, the aqueous solution of chloroauric acid and the sodium borohydride, TOAB, DDT, and 3-mercaptopropionic acid toluene solution were mixed and stirred evenly, and the chloroauric acid was reduced into gold nanoparticles with an average particle size of 2nm.

[0055] Take 0.5mL of ...

Embodiment 2

[0058] Take 3g of glucose and 30mL of pure water and mix them in a 50mL reactor, heat to 180°C and react for 10h to obtain a carbon nanosphere sol with an average particle size of 300nm, which is washed and dried.

[0059] Disperse 0.15g of TTIP and 5mL of oleic acid in toluene, dissolve 0.1mL of tert-butylamine in water, mix the toluene solution of TTIP and oleic acid with the aqueous solution of tert-butylamine in a 50mL reactor, heat to 180°C for 4h, and obtain the average Titanium dioxide nano-sol with a particle size of 4nm.

[0060] Get 0.09mmol chloroauric acid, 0.9mmol sodium borohydride, 0.18mmol TOAB, 0.09mmol DDT and 0.09mmol 3-mercaptopropionic acid, chloroauric acid is dissolved in water, the aqueous solution of chloroauric acid and the sodium borohydride, TOAB, DDT, and 3-mercaptopropionic acid toluene solution were mixed and stirred evenly, and the chloroauric acid was reduced into gold nanoparticles with an average particle size of 2nm.

[0061] Take 0.5mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com