Core shell nanometer crystal of gold and copper-indium-diselenide and preparation method of core shell nanometer crystal

A copper indium selenide and nanocrystalline technology, applied in the coating and other directions, can solve the problems of low collection rate and too much photogenerated carriers, and achieve the effects of improving photoelectric conversion performance, single product, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

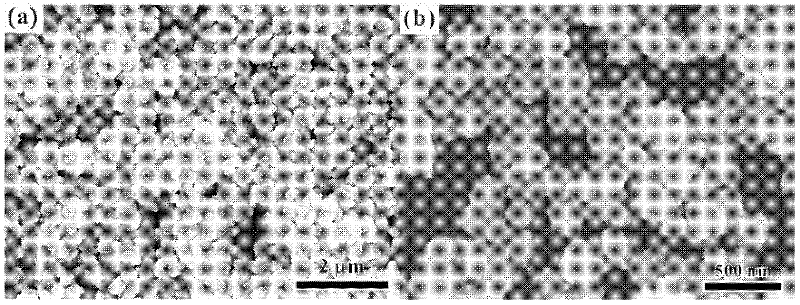

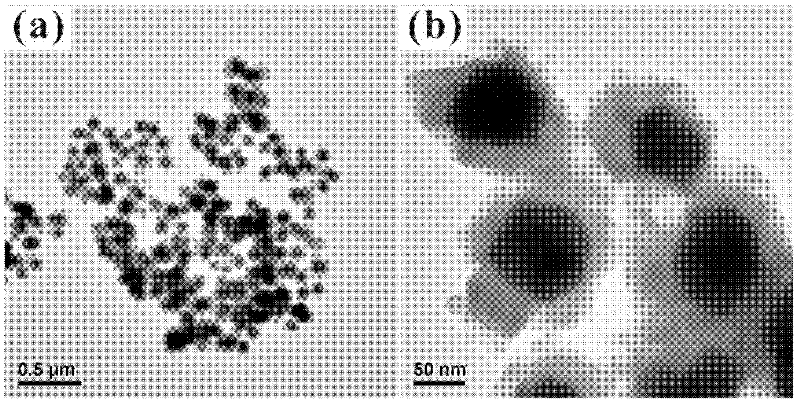

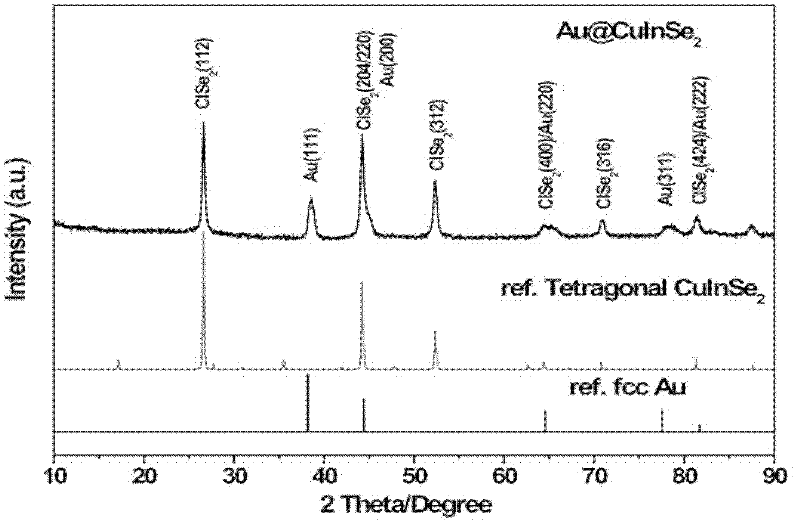

Image

Examples

Embodiment 1

[0031](1) In a 25mL three-necked round-bottomed flask, add 32mg of triphenylphosphine gold chloride and 5mL of oleylamine, ultrasonically disperse at room temperature for 5min, place the three-necked flask in a magnetic heating stirrer, and connect the temperature on the left side The probe, the middle port is connected to the reflux condenser, the right side is connected to the anti-port plug, and the temperature is raised to 80°C while magnetic stirring, and the vacuuming and nitrogen gas are repeated for 3 times, and the vacuuming time is at least 10 minutes each time, so that the vacuum degree of the system reaches -0.1MPa. Then, it was heated to 120° C. under a nitrogen atmosphere, and reacted at a constant temperature for 0.5 h.

[0032] (2) Add 44mg of selenium powder and 10mL of oleylamine to a 50mL three-neck round bottom flask, and disperse ultrasonically at room temperature for 10 minutes. The middle port is connected to a reflux condenser, and the temperature is ra...

Embodiment 2

[0039] (1) In a 25mL three-necked round-bottomed flask, add 64mg of triphenylphosphine gold chloride and 5mL of oleylamine, ultrasonically disperse at room temperature for 5min, place the three-necked flask in a magnetic heating stirrer, and connect the temperature on the left side The probe, the middle port is connected to the reflux condenser, the right side is connected to the anti-port plug, and the temperature is raised to 80°C while magnetic stirring, and the vacuuming and nitrogen gas are repeated for 3 times, and the vacuuming time is at least 10 minutes each time, so that the vacuum degree of the system reaches -0.1MPa. Then, it was heated to 120° C. under a nitrogen atmosphere, and reacted at a constant temperature for 0.5 h.

[0040] (2) Add 44mg of selenium powder and 10mL of oleylamine to a 50mL three-neck round bottom flask, ultrasonically disperse at room temperature for 10min, place the three-neck flask in a magnetic heating stirrer, and connect the temperature ...

Embodiment 3

[0046] (1) In a 25mL three-necked round-bottomed flask, add 32mg of triphenylphosphine gold chloride and 5mL of oleylamine, ultrasonically disperse at room temperature for 5min, place the three-necked flask in a magnetic heating stirrer, and connect the temperature on the left side The probe, the middle port is connected to the reflux condenser, the right side is connected to the anti-port plug, and the temperature is raised to 80°C while magnetic stirring, and the vacuuming and nitrogen gas are repeated for 3 times, and the vacuuming time is at least 10 minutes each time, so that the vacuum degree of the system reaches -0.1MPa. Then, it was heated to 120° C. under a nitrogen atmosphere, and reacted at a constant temperature for 0.5 h.

[0047] (2) Add 44mg of selenium powder and 15mL of oleylamine to a 50mL three-neck round bottom flask, ultrasonically disperse at room temperature for 10min, place the three-neck flask in a magnetic heating stirrer, and connect the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com