Preparation method of granular activated carbon by chemical activation

A granular activated carbon, chemical activation technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., to achieve the effects of low cost, promotion of development, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

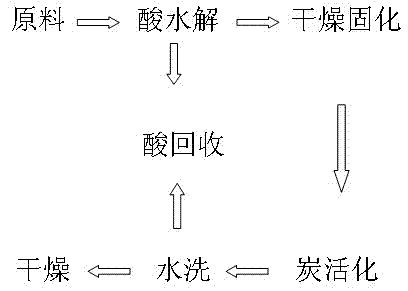

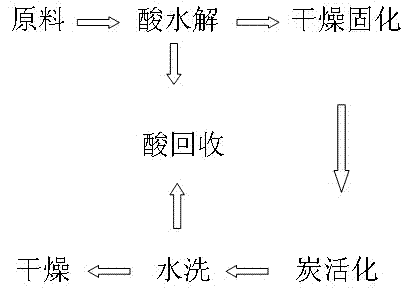

Method used

Image

Examples

Embodiment 1

[0027] Dry the camellia oleifera shell at 100°C, mix it with 50%wt phosphoric acid solution at a weight ratio of 1.5:1 and let it stand for 20 hours, then place the mixture in an oven for 2 hours at 110°C, and then recover Dry and harden the excess phosphoric acid solution in an oven at 230°C for 6 hours, and finally put it into an activation furnace for activation at 450°C for 45 minutes. Put it into an oven and bake it at 150°C until it reaches a constant weight, so that high-performance unshaped granular activated carbon can be produced. After testing: the iodine adsorption value reaches 1053 mg / g, the methylene blue adsorption value reaches 202 (13.5ml) mg / g, the granular carbon strength is greater than 90%, and the yield rate is 40%.

Embodiment 2

[0029] Dry the camellia oleifera shell at 100°C, mix the camellia oleifera shell with 70% phosphoric acid solution in a weight ratio of 2:1 and place it in an oven for 6 hours at 70°C, then recover the excess phosphoric acid solution and dry it in an oven at 230°C Dry and harden at ℃ for 6 hours, and finally put it into the activation furnace and activate it at 450℃ for 45min. Constant weight, high-performance unshaped granular activated carbon can be prepared. After testing: the iodine adsorption value reaches 970 mg / g, the methylene blue adsorption value reaches 187.5 (12.5ml) mg / g, the granular carbon strength is greater than 85%, and the yield rate is 37%.

Embodiment 3

[0031] Dry the camellia oleifera shell at 100°C, mix the camellia oleifera shell with 50% phosphoric acid solution in a weight ratio of 3:1 and place it in an oven for 10 hours at 70°C, then recover the excess phosphoric acid solution and dry it in an oven at 230 Dry and harden at ℃ for 6 hours, and finally put it into the activation furnace and activate it at 450℃ for 45min. Constant weight, high-performance unshaped granular activated carbon can be prepared. After testing: the iodine adsorption value reaches 940 mg / g, the methylene blue adsorption value reaches 225 (15ml) mg / g, the strength of granular carbon is greater than 90%, and the yield rate is 37%. Example 4 :

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption value of blue | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com