Sweetcane bark fiber composite and preparation method thereof

A fiber composite material and composite material technology, applied in the field of fiber composite material and its preparation, to achieve the effects of temperature control, easy mixing and heat transfer, and excellent hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

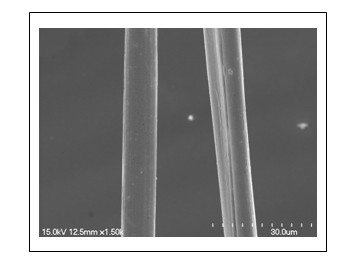

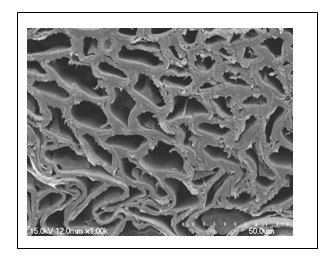

[0028] 1. Fiber extraction

[0029] Cut sugarcane bark into small sections about 70 mm in length and wash them with clean water.

[0030] Take an appropriate amount of sugarcane peel and add it to clean water, the bath ratio is 1:50, put it in a water bath and boil for 1 hour, replace with new clean water and boil for another 2 hours, then change the water and boil for 1 hour. Take out the sugarcane skin and wash it, put it in a 55°C oven and dry it for later use.

[0031] Take the cleaned and dried sugarcane bark for fiber extraction according to the following process:

[0032] Take 30g of sugarcane skin, put it into 600ml of hydrochloric acid and formic acid mixed solution, the solution contains 15ml of hydrochloric acid with a mass concentration of 36-38%, and 60ml of formic acid with a mass concentration of 88%, stir at 80°C for 60min; take out the solid Wash it with water, put it into 600ml of NaOH solution with a mass concentration of 10%, and stir it at 75°C for 120 m...

Embodiment 2

[0052] Remove the bark of sugarcane and cut it into small sections, wash it with clean water. Take an appropriate amount of sugarcane peel and add it to clean water, the bath ratio is 1:50, put it in a water bath and boil for 1 hour, replace with new clean water and boil for another 2 hours, then change the water and boil for 1 hour. Take out the sugarcane skin and wash it, put it in a 55°C oven and dry it for later use.

[0053] Take the cleaned and dried sugarcane bark for fiber extraction according to the following process:

[0054] Take 30g of sugarcane skin, put it into 600ml of hydrochloric acid and formic acid mixed solution, the solution contains 15ml of hydrochloric acid, 60ml of formic acid, stir at 80°C for 60min; take out the solid matter and wash it with water, then put it into 600ml of 10% NaOH solution, Stir at 75°C for 120 minutes; take out the fiber and wash it, add dilute acetic acid solution to neutralize it, rinse it repeatedly with water, take it out, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com