Preparation method of up-conversion fluorescence/paramagnetic difunctional nanocrystal

A paramagnetic, bifunctional technology, applied in the field of preparation of up-conversion fluorescent/paramagnetic bifunctional nanocrystals, can solve problems such as no public reports, and achieve huge industrial development prospects, high energy utilization, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

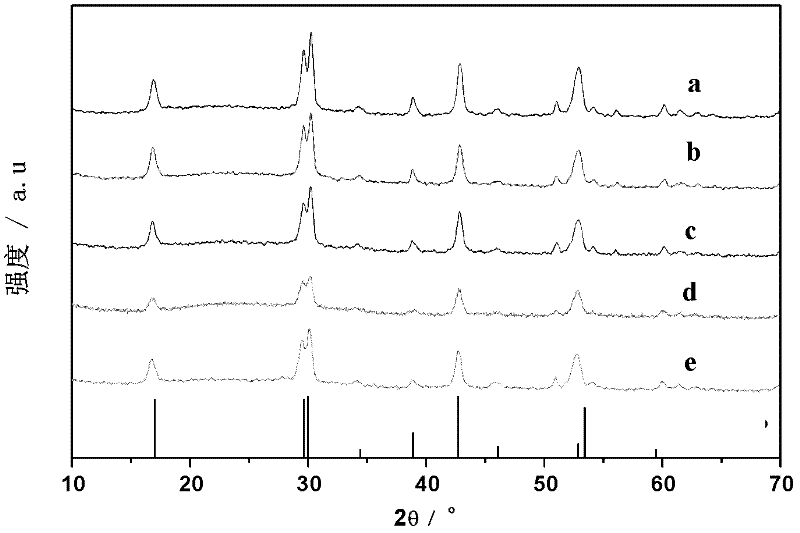

Embodiment 1

[0036] (a) According to the molar ratio of 80% Gd, 18% Yb, 2% Er, accurately weigh 725mg (2mmol) Gd of rare earth oxide 2 o 3 , 177.35 mg (0.45 mmol) Yb 2 o 3 , 19.13 mg (0.05 mmol) Er 2 o 3 In a 50ml flask, add 5ml of pure water and 5ml of concentrated hydrochloric acid with a concentration of 37.5%, seal it tightly, heat it in a water bath at 80-85°C and stir it magnetically to dissolve it completely, then heat the solution slowly until it evaporates to dryness, and then make it to volume In a 25ml volumetric flask, get 0.2mol / L of LnCl 3 (Ln=80%Gd, 18%Yb, 2%Er) Solution A, sealed and stored for future use.

[0037] (b) Put 0.8g NaOH, 4ml H 2 O, 13ml oleic acid, and 7ml ethanol were mixed during stirring to obtain a homogeneous transparent solution B.

[0038] (c) During the stirring process, add 2ml 02mol / L solution A and 3ml 1mol / LNaF solution successively to solution B to obtain homogeneous translucent solution C.

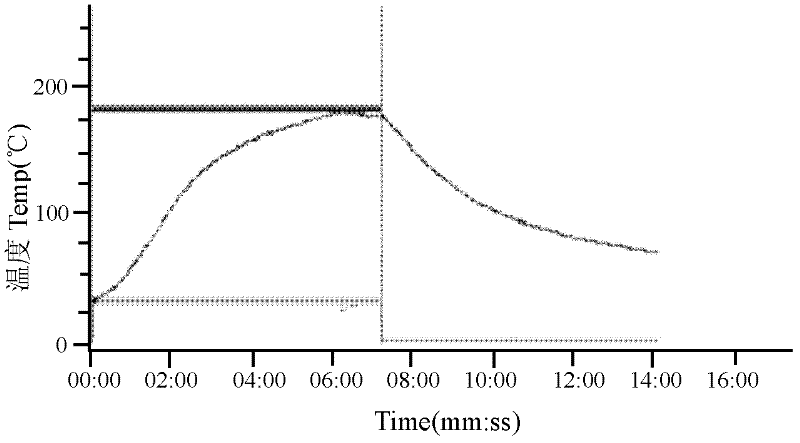

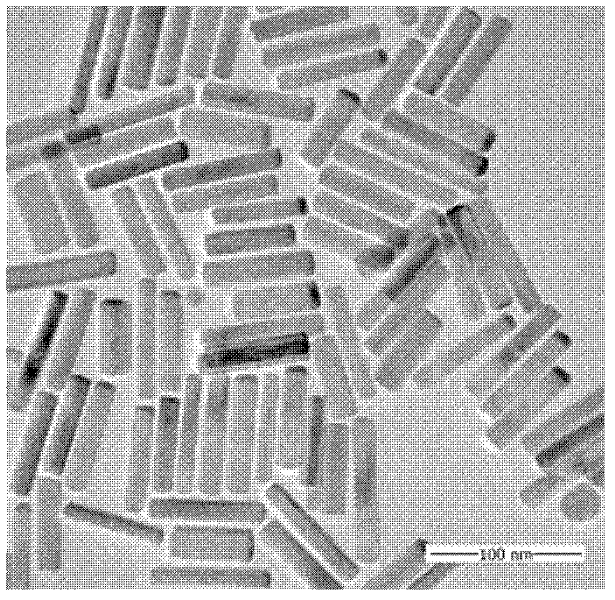

[0039] (d) Take 7ml of the reactant solution fro...

Embodiment 2

[0044] (a) According to the molar ratio of 78% Gd, 20% Yb, 2% Er, accurately weigh 1.41g (3.9mmol) Gd of rare earth oxide 2 o 3 , 394.08 mg (1 mmol) Yb 2 o 3 , 38.25 mg (0.1 mmol) Er 2 o 3 Add 10ml of pure water and 10ml of 37.5% concentrated hydrochloric acid to the flask, seal it tightly, heat it in a water bath at 80-85°C and stir it magnetically to dissolve it completely, then heat the solution slowly until it evaporates to dryness, and then set the volume to 25ml volumetric flask, to obtain 0.4mol / L of LnCl 3 (Ln=78%Gd, 20%Yb, 2%Er) Solution A, sealed and stored for future use.

[0045] (b) Put 0.8g NaOH, 4ml H 2 O, 13ml oleic acid, and 7ml ethanol were mixed during stirring to obtain a homogeneous transparent solution B.

[0046] (c) During stirring, add 1ml of 0.4mol / L solution A and 3ml of 1mol / L NaF solution to solution B to obtain homogeneous translucent solution C

[0047] (d) Take 5ml of the reactant solution from C and add it to the 10mL quartz reactor of ...

Embodiment 3

[0050] (a) Accurately weigh 1078.44mg (2.975mmol) Gd of rare earth oxide according to the molar ratio of 59.5%Gd, 40%Yb, 0.5%Tm 2 o 3 , 788.16mg (2.0mmol) Yb 2 o 3 , 9.65mg (0.025mmol) Tm 2 o 3 Add 5ml of pure water and 3ml of 68% concentrated nitric acid to the flask, seal it tightly, heat it in a water bath at 80-85°C and stir it magnetically to dissolve it completely, then heat the solution slowly until it evaporates to dryness, and then set the volume to 25ml Volumetric flask, get 0.4mol / L LnNO 3 (Ln=59.5% Gd, 40% Yb, 0.5% Tm) Solution A, sealed and stored for future use.

[0051] (b) Put 0.8g NaOH, 4ml H 2 O, 13ml oleic acid, and 7ml ethanol were mixed during stirring to obtain a homogeneous transparent solution B.

[0052] (c) During the stirring process, add 2ml 0.4mol / L solution A and 6ml 1mol / L NaF solution to solution B successively to obtain homogeneous translucent solution C.

[0053] (d) Take 5ml of the reactant solution from C and add it to the 10mL quart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com