Method for preparing polyoxometallate composite mesoporous material by electrostatic spinning

A polyoxometalate and electrospinning technology, which is used in the preparation of spinning solutions, textiles and papermaking, and rayon of inorganic raw materials, etc., to achieve the effects of convenient operation, good repeatability and quick preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 0.5g of surfactant P123 to 10g of absolute ethanol and stir for 3 hours to fully disperse the surfactant in the solvent; add 0.3g of polyoxometalate H 3 PW 12 o 40 , and continued stirring for 1 hour to form a homogeneous solution. Continue to add 1.5 g of polyvinylpyrrolidone (PVP), and continue to stir for 2 hours until the polymer is completely dissolved. Next, 2 g of tetraethoxysilane (TEOS) was added, stirred for 30 minutes, and then heated and stirred at 110° C. for 1 hour to form a clear colloidal solution.

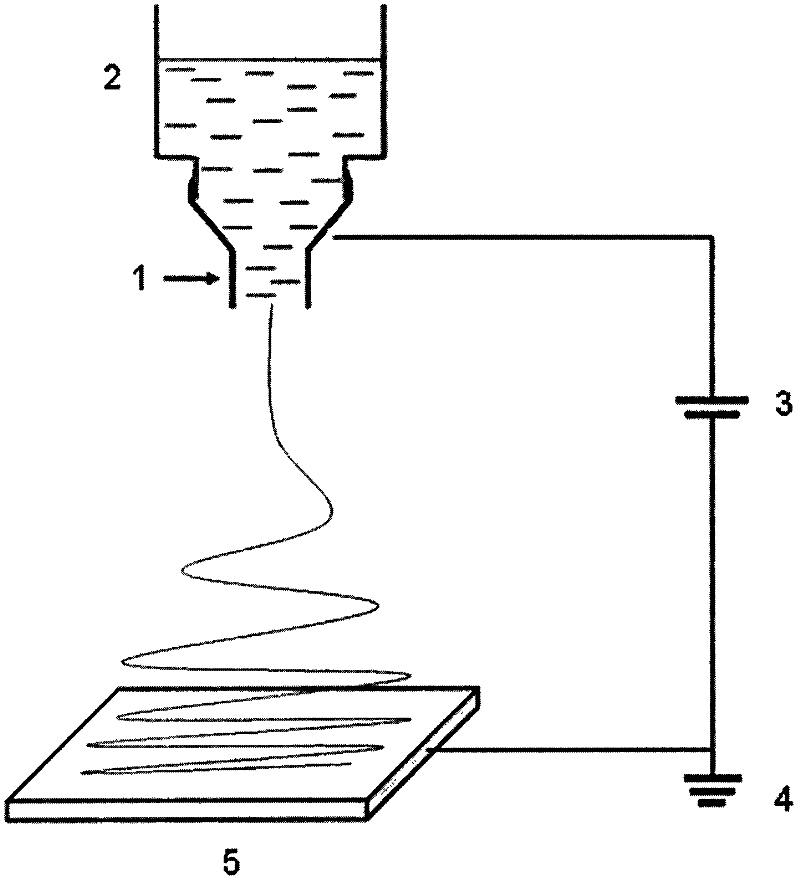

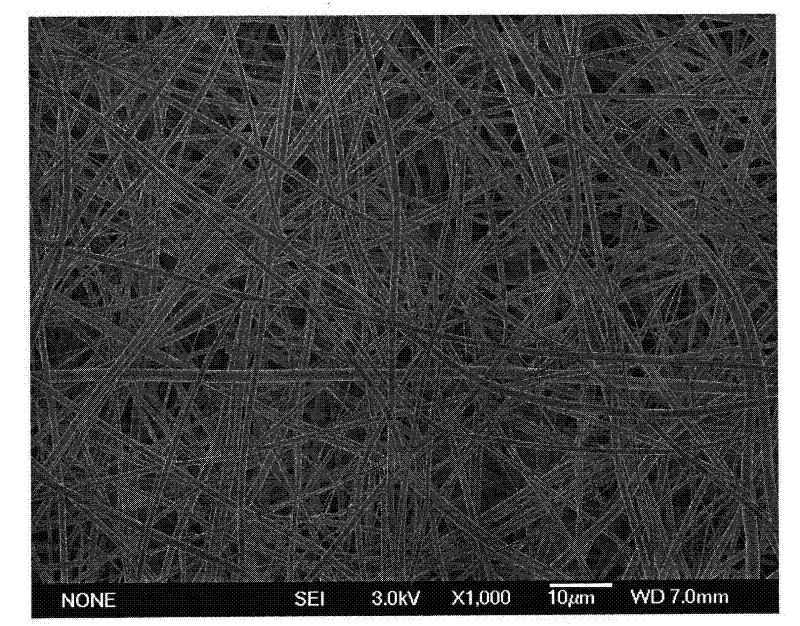

[0042] Add 10mL of the prepared clear colloidal solution into the liquid storage tube on the nozzle through a pipette, connect the nozzle to the positive electrode of the high-voltage electrostatic generator, and the metal plate covered with aluminum foil on the surface is grounded and used as a collecting plate. The working voltage is 20kv. The distance between the composite nozzle and the collecting plate is 35cm, and the high-voltage electrospinnin...

Embodiment 2

[0045] Add 0.3g of surfactant P123 to 18g of absolute ethanol and stir for 1 hour to fully disperse the surfactant in the solvent; add 0.1g of polyoxometalate H 4 SiW 12 o 40 , and continued to stir for 1.5 hours to form a homogeneous solution. Continue to add 1.9 g of polyvinylpyrrolidone (PVP), and continue stirring for 1 hour until the polymer is completely dissolved. Next, 1.1 g of tetraethoxysilane (TEOS) was added, stirred for 30 minutes, and then heated and stirred at 100° C. for 2 hours to form a clear colloidal solution.

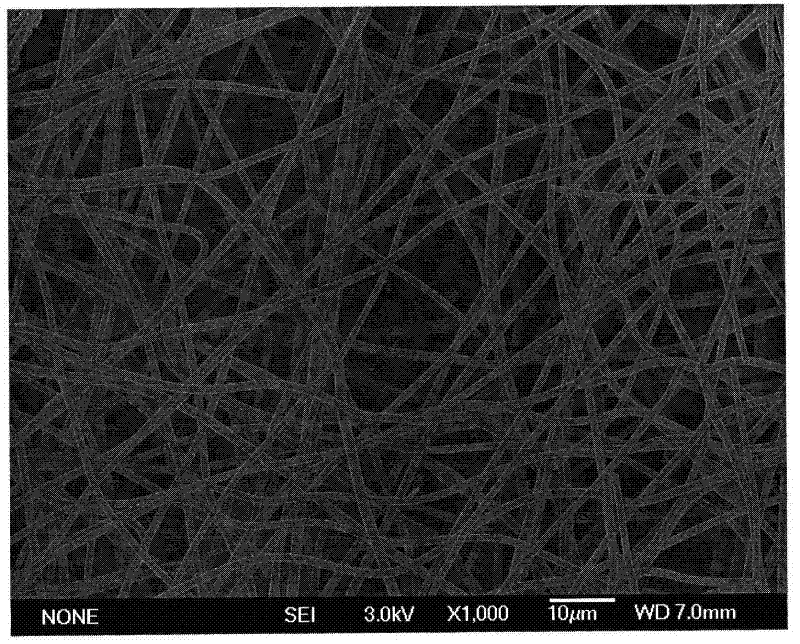

[0046] Add 5mL of the prepared clear colloidal solution into the liquid storage tube on the nozzle through a pipette, connect the nozzle to the positive electrode of the high-voltage electrostatic generator, and the metal plate covered with aluminum foil on the surface is grounded and used as a collecting plate. The working voltage is 25kv. The distance between the composite nozzle and the collecting plate is 28cm, and the high-voltage electrospi...

Embodiment 3

[0049] Add 0.7g of surfactant cetyltrimethylammonium bromide (CTAB) to 14g of methanol and stir for 1.5 hours to fully disperse the surfactant in the solvent; add 0.2g of polyoxometalate Cs 3 PMo 12 o 40 , and continued to stir for 2 hours to form a homogeneous solution. Continue to add 0.9g of polyacrylic acid, and continue to stir for 5 hours until the polymer is completely dissolved. Next, 1.8 g of tetrabutyl titanate was added, stirred for 1 hour, and then heated and stirred at 40° C. for 12 hours to form a pale yellow clear colloidal solution.

[0050] Add 7mL of the prepared clear colloidal solution into the liquid storage tube on the nozzle through a pipette, connect the nozzle to the positive electrode of the high-voltage electrostatic generator, and the metal plate covered with aluminum foil on the surface is grounded and used as a collecting plate. The working voltage is 30kv. The distance between the composite nozzle and the collecting plate is 38cm, and the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com