Synchronous remover for mixed impurities of ink and adhesive in waste paper, and preparation method thereof

A sticky matter and remover technology, which is applied in the field of sticky matter removal and ink in waste paper pulping, can solve the problems that cannot meet the needs of production practice, and achieve the goals of reducing energy consumption, easy preparation, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

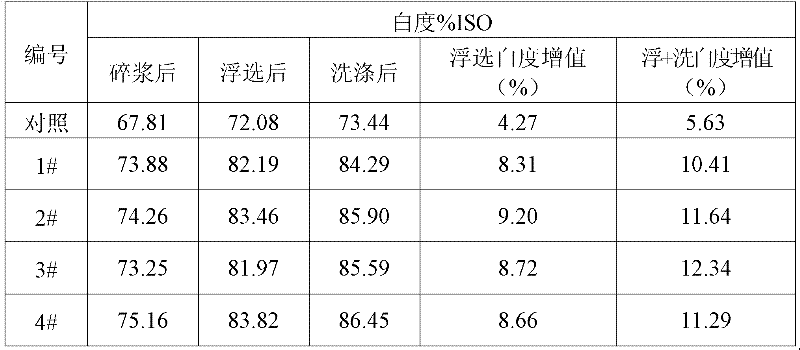

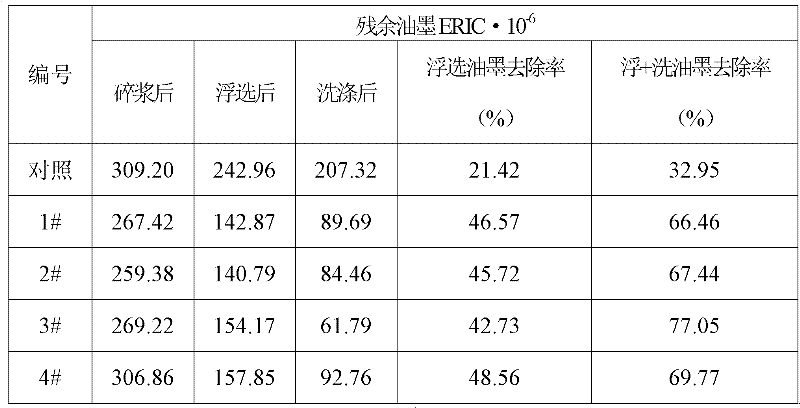

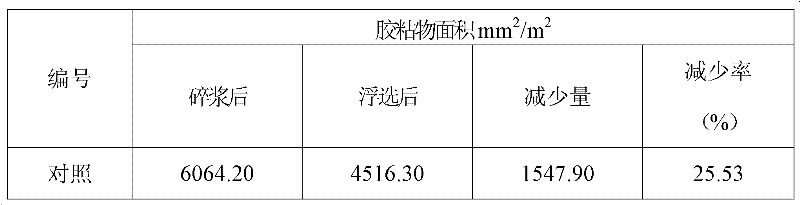

Examples

Embodiment 1

[0029] (1) The alkaline pulping waste liquid is prepared into a solution with a mass fraction of 10%, and the lignin raw material in the solution is classified by an ultrafilter, and the part with a molecular weight between 3000 and 5000 is taken, concentrated and dried to obtain Refined lignin raw materials;

[0030] (2) Take 100g of refined lignin raw material, add 600ml of 10% NaOH solution and 1500ml of 37% formaldehyde solution, then add water to 2500ml, and react at 80°C for 2h; after the reaction, adjust the pH with 10% dilute hydrochloric acid < 3. The product was precipitated, centrifuged, the supernatant was removed, the precipitate was washed 3 times with water with pH=2, and then vacuum-dried at 35°C to obtain a lignin-modified product;

[0031] (3) calcining diatomite raw soil at 500°C for 0.5h to obtain calcined diatomite;

[0032] (4) Add 400ml of water to the reactor, put 100g of calcined diatomaceous earth into the reactor, and dissolve 1g of dodecyltrimethyl...

Embodiment 2

[0036] (1) Adjust the acidic sulfite pulping waste liquid into a solution with a mass fraction of 12%, use an ultrafilter to classify the lignin raw material in the solution, take the part with a molecular weight between 3000 and 5000, concentrate and dry processing to obtain refined lignin raw materials;

[0037] (2) Get 100g of refined lignin raw material, add 1000ml10% NaOH solution and 1500ml37% formaldehyde solution, then add water to 3000ml, react at 40°C for 5h; Vacuum drying at ℃ to obtain a lignin modified product;

[0038] (3) calcining bentonite raw soil at 300°C for 1.5h to obtain calcined bentonite;

[0039] (4) Add 400ml of water to the reactor, put 100g of calcined diatomaceous earth into the reactor, and dissolve 5g of cetyltrimethylammonium chloride in 100ml of water, add it to the reactor, and then react Put the device into the ultrasonic generator, and ultrasonically treat it for 48 hours at a frequency of 80KHz and a temperature of 60°C;

[0040] (5) Aft...

Embodiment 3

[0043] (1) Prepare lignosulfonate into a solution with a mass fraction of 10%, use an ultrafilter to classify the lignin raw material in the solution, take the part with a molecular weight between 3000 and 5000, concentrate and dry it, and obtain refined lignin raw material;

[0044] (2) Get 200g of refined lignin raw material, add 1200ml10% NaOH solution and 2000ml37% formaldehyde solution, then add water to 3500ml, and react at 60°C for 3h; after the reaction is completed, the reaction solution is concentrated by rotary evaporation, and then Vacuum drying at 50°C to obtain a lignin-modified product;

[0045](3) calcining palygorskite raw soil at 400°C for 1 hour to obtain calcined palygorskite;

[0046] (4) Add 400ml of water to the reactor, put 100g of calcined diatomaceous earth into the reactor, and dissolve another 3g of tetradecyltrimethylammonium bromide with 100ml of water, add it to the reactor, and then react Put the device into an ultrasonic generator, and ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com