Water base fracturing and blocking-removing composite process

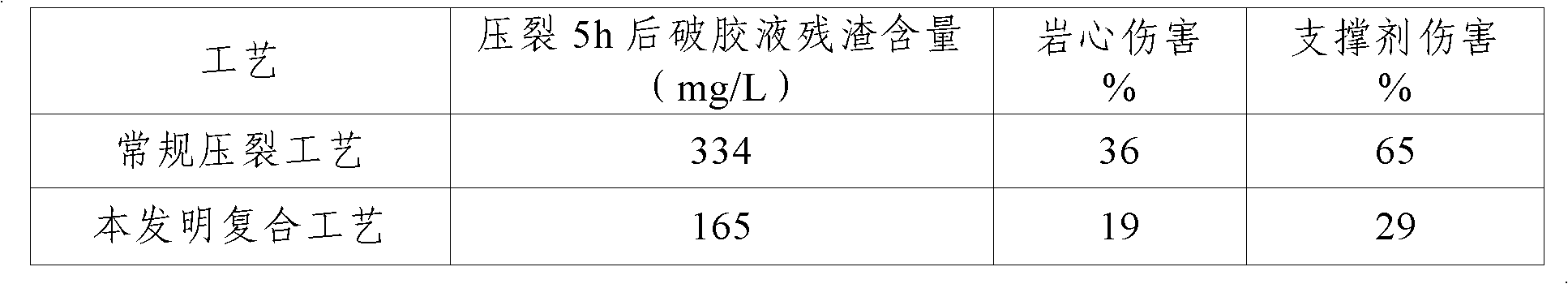

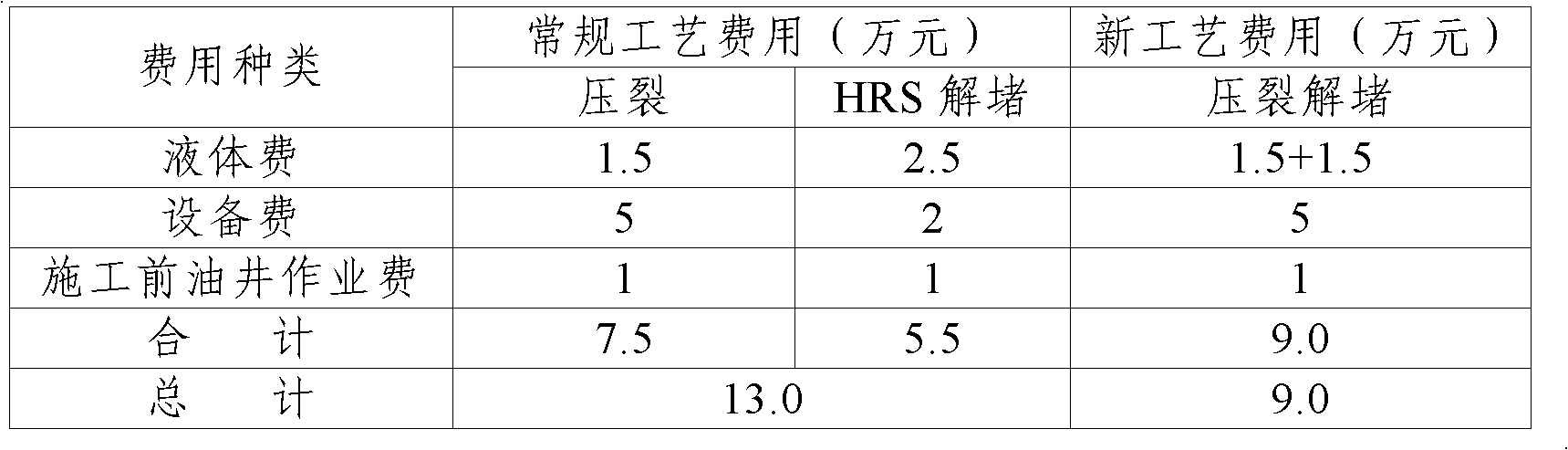

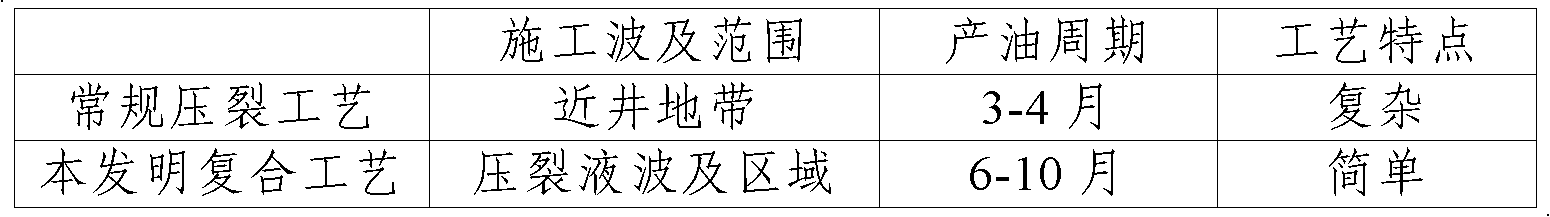

A composite process and water-based fracturing technology, which is applied in the direction of drilling composition, production fluid, wellbore/well components, etc., can solve the problems of increasing construction unsafety, affecting the effect of plugging removal, and decreasing the use concentration. Achieve the effect of wide range of blocking, effective effect of blocking, and reduction of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1. Add HRS compound plugging agent into the water, stir well, then add clay stabilizer potassium chloride and demulsification and drainage aid CF-5C (produced by Changqing underground chemical factory in Qingyang, Gansu Province), stir well and then add Hydroxypropyl guar gum, stir 10min to obtain former glue solution; The mass concentration of hydroxypropyl guar gum in the described former glue solution is 0.1%, and the mass concentration of clay stabilizer is 0.5%, and the mass concentration of demulsification aid-drainage agent is 0.1%, the mass concentration of compound plugging agent HRS is 0.1%;

[0026] Step 2, mixing the original gum solution and the crosslinking agent described in step 1 at a volume ratio of 100:6 and then stirring evenly to obtain a fracturing fluid; the crosslinking agent is a mixed aqueous solution of sodium tetraborate and ammonium persulfate, The mass concentration of sodium tetraborate in the crosslinking agent is 0.4%, and the mass ...

Embodiment 2

[0029] Step 1. Add HRS compound plugging agent into the water, stir well, then add clay stabilizer potassium chloride and demulsification and drainage aid CF-5C (produced by Changqing underground chemical factory in Qingyang, Gansu Province), stir well and then add Hydroxypropyl guar gum, stir 20min to obtain former gum solution; The mass concentration of hydroxypropyl guar gum in the described former gum solution is 1%, and the mass concentration of clay stabilizer is 2.5%, and the mass concentration of demulsification aid-drainage agent is 1%, the mass concentration of composite plugging agent HRS is 0.5%;

[0030] Step 2, mixing the original gum solution and the cross-linking agent described in step 1 at a volume ratio of 100:10 and stirring evenly to obtain a fracturing fluid; the cross-linking agent is a mixed aqueous solution of sodium tetraborate and ammonium persulfate, The mass concentration of sodium tetraborate in the crosslinking agent is 1%, and the mass concentra...

Embodiment 3

[0033] Step 1. Add HRS compound plugging agent into the water, stir well, then add clay stabilizer potassium chloride and demulsification and drainage aid CF-5C (produced by Changqing underground chemical factory in Qingyang, Gansu Province), stir well and then add Hydroxypropyl guar gum, stir 10min to obtain former gum solution; The mass concentration of hydroxypropyl guar gum in the described former gum solution is 0.3%, and the mass concentration of clay stabilizer is 1%, and the mass concentration of demulsification aid-drainage agent is 0.3%, the mass concentration of compound plugging agent HRS is 0.2%;

[0034] Step 2, mixing the original gum solution and the crosslinking agent described in step 1 at a volume ratio of 100:6 and then stirring evenly to obtain a fracturing fluid; the crosslinking agent is a mixed aqueous solution of sodium tetraborate and ammonium persulfate, The mass concentration of sodium tetraborate in the crosslinking agent is 0.6%, and the mass conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com