Method for determining lead content of cigarette paper

A technology for cigarette paper and lead content, which is applied to measurement devices, preparation of test samples, and color/spectral property measurement, etc., can solve the problems of limitation, expensive equipment, and high detection sensitivity, and achieves good accuracy, simple method, and high sensitivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 Digestive agent experiment

[0021] 1. Materials and instruments

[0022] MF60-32S vertical ribbed cigarette paper, 65% nitric acid, 30% hydrogen peroxide and ammonium dihydrogen phosphate are excellent grade pure; hydrochloric acid, hydrofluoric acid, palladium nitrate, magnesium nitrate and ascorbic acid are analytical pure; test water is high purity water; Lead standard solution (National Iron and Steel Material Testing Center Iron and Steel Research Institute).

[0023] AA-6800 Atomic Absorption Spectrometer (Shimadzu, Japan); Ethos1 Microwave Digestion Apparatus (China Labtech Co., Ltd.); 7500A Inductively Coupled Plasma Mass Spectrometer (Agilent, USA).

[0024] 2. Sample processing

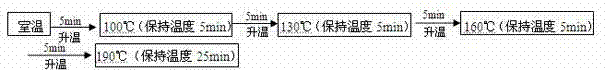

[0025] Weigh 0.3000g of cigarette paper, add different digestion agents (Table 1), press figure 1 The procedure shown for microwave digestion:

[0026] After the digestion is complete, transfer the sample to a 25mL volumetric flask to make the volume constant.

[0027] Table 1 Com...

Embodiment 2

[0046] Example 2 Cigarette paper quality test

[0047] In order to study the influence of the quality of cigarette paper on the determination of lead content, 0.2000 g, 0.3000 g, 0.4000 g, and 0.5000 g cigarette paper were weighed with an analytical balance and digested with digester 3 for microwave digestion, and then the lead content was detected by graphite furnace atomic absorption method , The results are shown in Table 3.

[0048] Table 3 Lead content measured after digestion of different quality cigarette paper

[0049]

[0050] Note: Use digester 3 for digestion, the ashing temperature is 700 ℃, the atomization temperature is 1900 ℃, and the matrix modifier is 0.10 g / L ammonium dihydrogen phosphate. The standard deviation is calculated based on the 10 test results.

[0051] It can be seen from Table 3 that when the mass of cigarette paper is 0.2000 g, the standard deviation of the detected lead content is larger, which is 0.036 mg / kg. This is because the quality of cigar...

Embodiment 3

[0052] Example 3 Ashing temperature experiment of graphite furnace atomic absorption spectrometry

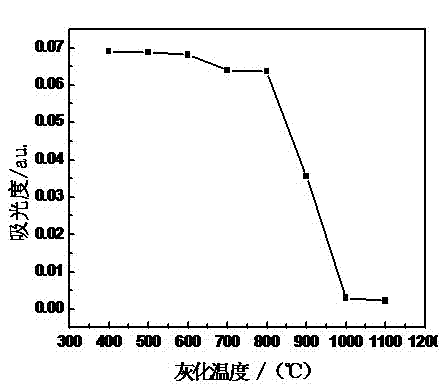

[0053] When the atomization temperature is 1900℃, add 0.10g / L ammonium dihydrogen phosphate as the matrix modifier, change the ashing temperature, the change trend of absorbance is as follows image 3 Shown.

[0054] Such as image 3 As shown, when the atomization temperature is 1900℃, the absorbance is larger at a lower ashing temperature, and it has a strong matrix effect; when the ashing temperature is 700℃~800℃, the influence of the matrix effect is small; 800℃ Then the absorbance decreases with the increase of ashing temperature. The function of the ashing stage is to remove all or most of the coexisting substances in the sample as much as possible, and to ensure that there is no loss of the elements to be analyzed. Therefore, it is necessary to choose a suitable ashing temperature. When the ashing temperature is low, the coexisting substances cannot be removed. When atomized,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com