Lentinus edodes dietary fiber slice and preparation method thereof

A technology of dietary fiber and shiitake mushrooms, applied in food preparation, food science, application, etc., can solve the problems of rough taste, poor solubility, and poor palatability of shiitake mushrooms, and achieve the goal of ensuring pure natural properties, high nutritional value, and lowering blood sugar Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1 Materials and reagents

[0052] Mushrooms (provided by Hangzhou Huadan Agricultural Products Co., Ltd.). Before use, dry in an oven at 50°C, pulverize, and sieve samples with a mesh size of 40-60 mesh for later use.

[0053] Total dietary fiber determination kit (TDF 100A-1KT, purchased from Sigma-Aldrich), konjac gum, xanthan gum, white sugar, ginger powder, salt, allspice powder, monoglycerides, and sucrose esters are all commercial food grade. Among them, konjac gum and xanthan gum were purchased from Hangzhou Jinjunke Biological Products Co., Ltd., and sucrose ester was sucrose fatty acid ester purchased from Zhejiang Dier Chemical Co., Ltd.

[0054] 2 experimental equipment

[0055] Pulverizer, AL04 electronic balance, HH-2 water bath, ZHENGFCHEN double-layer constant temperature shaker, DHG-9240A blast drying oven, 101-2y far-infrared drying oven, DL-5M centrifuge, 85-Z magnetic stirring Instrument, T6 new century spectrophotometer, muffle furnace, digestion ...

Embodiment 2

[0108] Embodiment 2: Homogenization parameters

[0109] The homogenization conditions in Step 3.1 of Example 1 were changed, and the other operations were the same as in Example 1 to prepare mushroom dietary fiber slices. The sensory evaluation was performed according to the sensory evaluation standards shown in Table 1, and the results are shown in Table 8.

[0110] Table 8 The influence of homogenization pressure and time on the homogeneity of shiitake mushroom dietary fiber homogeneity

[0111]

[0112] Note: The sensory evaluation is based on 100 points for a full score, and the closer to the homogeneous state and the finer the particles, the closer to the full score.

Embodiment 3

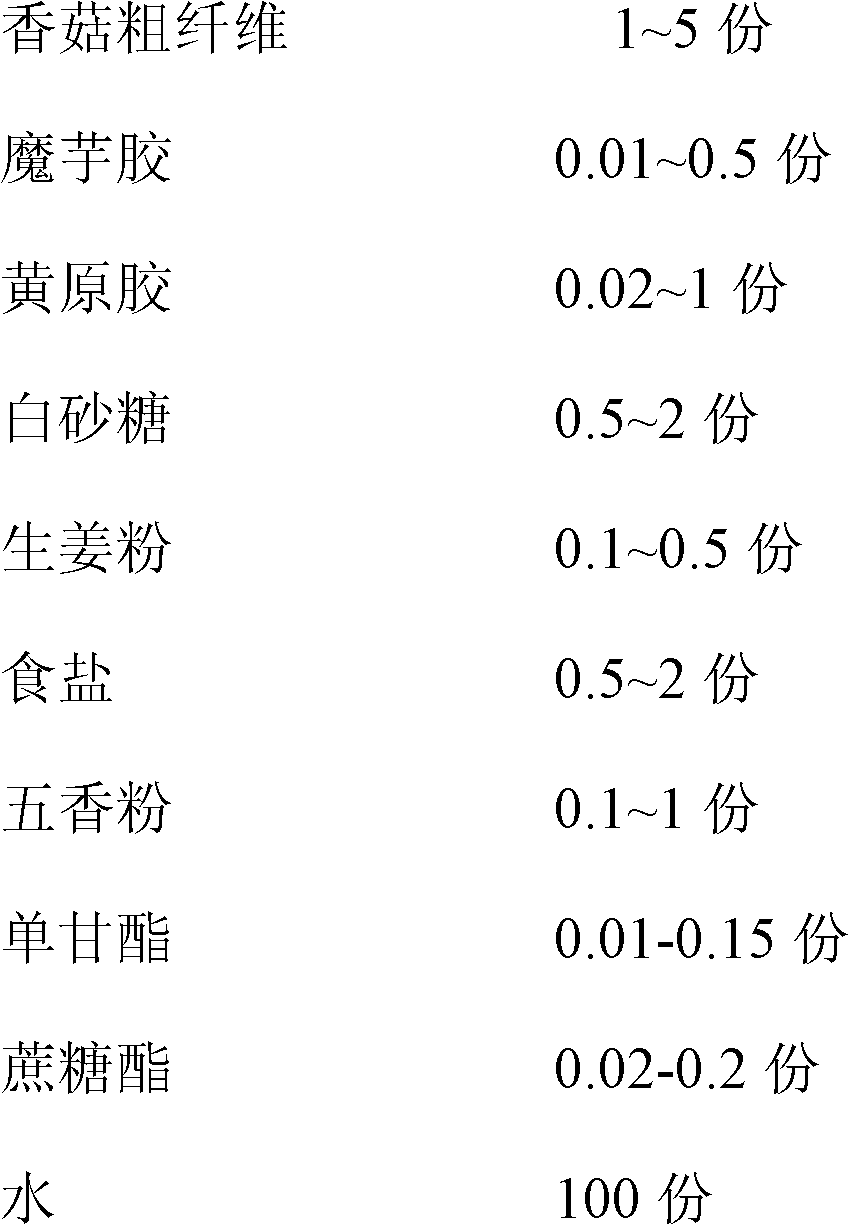

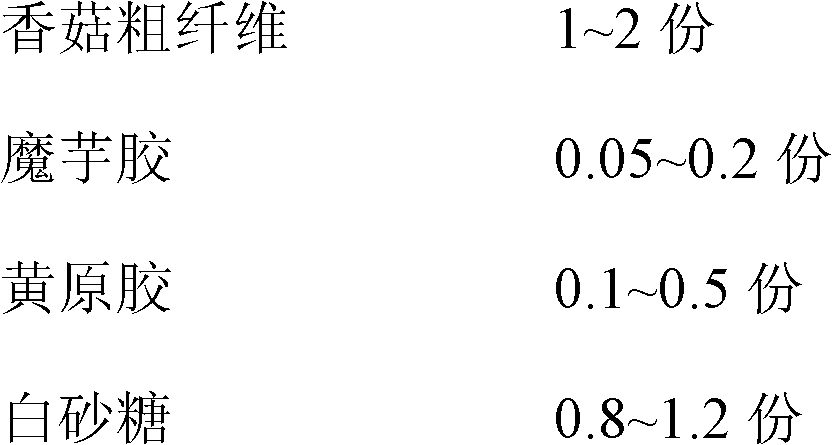

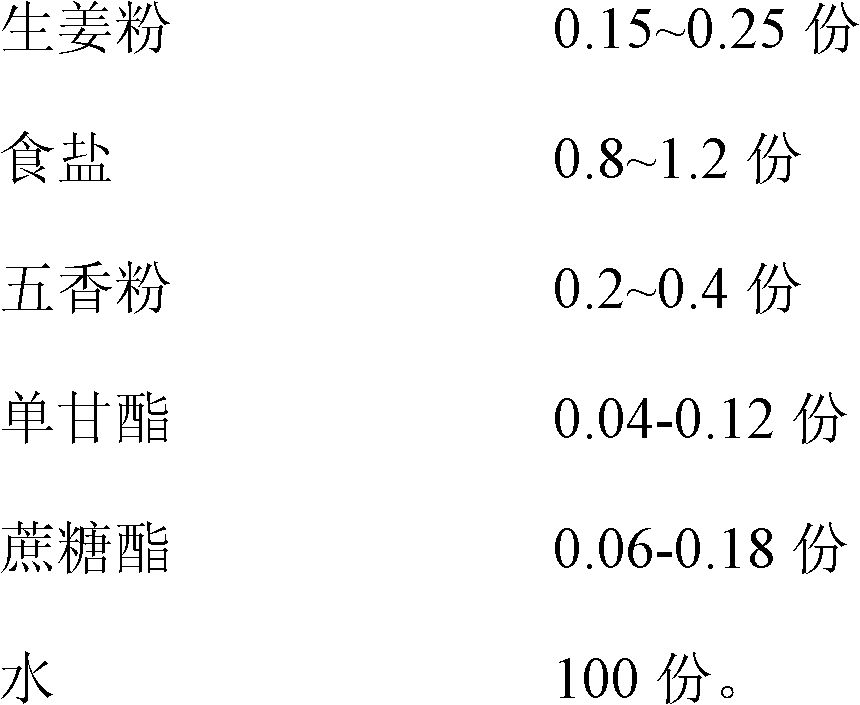

[0113] Embodiment 3: Composition ratio test of shiitake mushroom dietary fiber flakes

[0114] 3-1 Effects of added amount of konjac gum and xanthan gum on the taste of shiitake mushroom dietary fiber slices

[0115] The total consumption of konjac gum and xanthan gum (mass ratio 2:5) is 0.01 part (0.05g), 0.05 part (0.25g), 0.15 part (0.75g), 0.5 part (2.5g), 1.0 part (5g) ), 1.5 parts (7.5g), 2.0 parts (10g), 5.0 parts (25g), other material consumptions are with embodiment 1, and processing steps and other processing conditions are with embodiment 1, and product character is as shown in table 9.

[0116] Table 9 The effect of the addition of konjac gum and xanthan gum on the taste of shiitake mushroom dietary fiber slices

[0117]

[0118] It can be known from Table 9 that when the amount of konjac gum and xanthan gum is 0.15 parts, the shiitake mushroom dietary fiber flakes have a fine structure, high elasticity, moderate hardness and chewiness.

[0119] 3-2 Seasoning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com