Novel metal catalyst loaded by mesoporous carbon and preparation method thereof

A metal catalyst, mesoporous carbon technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst supports, preparation of amino compounds, etc., can solve the problem of low reaction selectivity, easy deactivation of catalysts, and limited catalyst applications and other problems, to achieve the effect of enhancing catalytic activity and simple metal loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

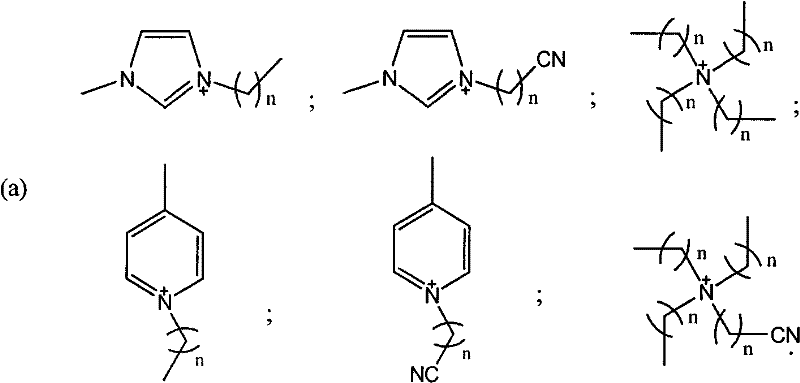

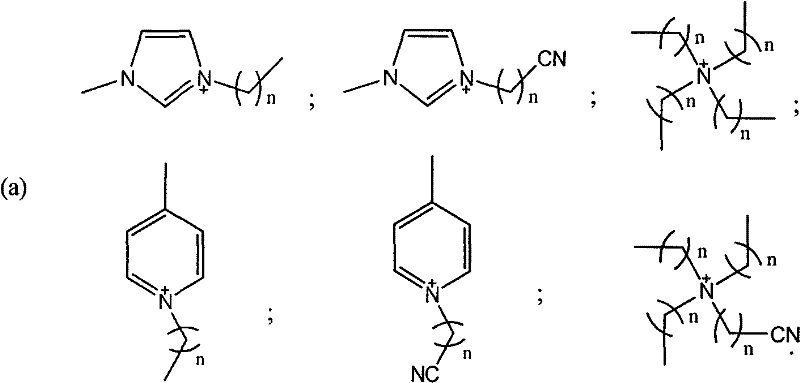

[0026] This embodiment provides a metal Pd catalyst supported by a mesoporous carbon material co-doped with nitrogen and phosphorus, which is prepared by the following steps:

[0027] (1). Mix 1g 1-pentylcyano-3-methylimidazole hexafluorophosphate ionic liquid with 1.5g molecular sieve SBA-15 at room temperature, then heat up to 600°C and calcinate for 3 hours, then use after cooling to room temperature Ammonium bifluoride decomposes and removes SBA-15 to obtain 0.6g of mesoporous carbon material co-doped with nitrogen and phosphorus. Elemental analysis shows that the mass content of nitrogen is 7.8%, the mass content of phosphorus is 0.2%, and its specific surface area is 150~1200m 2 / g.

[0028] (2) Add 0.2g of the mesoporous carbon material co-doped with nitrogen and phosphorus obtained in step (1) into a 250mL beaker, add 50-100mL deionized water, sonicate for 5-30 minutes, and then add 4ml to a concentration of 0.056 mmol / ml PdCl 2 Aqueous solution, ultrasonic vibration for 5-...

Embodiment 2

[0030] This embodiment provides a metal Au catalyst supported by a mesoporous carbon material co-doped with nitrogen, boron, and fluorine, which is prepared by the following steps:

[0031] (1). Mix 1g 4-methyl-N-pentylcyanopyridine tetrafluoroborate and 2g Ludox HS 40 silica sol at room temperature uniformly, then heat up to 800°C and calcinate for 3 hours, then use hydrogen fluoride after cooling to room temperature Ammonium decomposes the template Ludox-41 silica sol to obtain 0.5g of mesoporous carbon material co-doped with nitrogen, boron and fluorine. Elemental analysis shows that the mass fraction of nitrogen in the material is 5.6%, the mass fraction of boron is 0.2%, and the mass fraction of fluorine The mass fraction is 0.1%, and its specific surface area is 150~1200m 2 / g.

[0032] (2) Add 0.3g of the mesoporous carbon material co-doped with nitrogen, boron and fluorine obtained in step (1) into a 250mL beaker, add 50-100mL deionized water, sonicate for 5-30 minutes, and...

Embodiment 3

[0034] This embodiment provides a metal Pt catalyst supported by a mesoporous carbon material co-doped with nitrogen, boron, and fluorine, which is prepared by the following steps:

[0035] (1) Mix 1g 1-butyl-3-methylimidazole chloride salt and 1.5g MCM-41 uniformly at room temperature, then heat it up to 400℃ and calcinate for 3 hours, then use ammonium bifluoride to decompose the template after cooling to room temperature MCM-41, 0.6g of nitrogen-doped mesoporous carbon material is obtained, with a specific surface area of 150~1200m 2 / g.

[0036] (2) Add 0.3g of nitrogen-doped mesoporous carbon material into a 250mL beaker, add 50-100mL deionized water, sonicate for 5-30 minutes, then add 10ml of chloroplatinic acid aqueous solution with a concentration of 0.038mmol / ml , Sonicate for 5-30 minutes, and finally add 7mg NaBH 4 , Ultrasonic vibration for 5 to 60 minutes, filtration, washing, and drying to obtain a metal Pt catalyst supported by a mesoporous carbon material co-dope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com