Flux-cored wire for visible arc overlaying of high-chromium cast iron

A technology of high-chromium cast iron and high-carbon ferrochrome, which is applied in the direction of arc welding equipment, welding equipment, welding equipment, etc., can solve the problems of waste of surfacing welding materials, rising construction costs, and large weld penetration, so as to reduce construction costs , arc stability, ultra-high hardness and the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

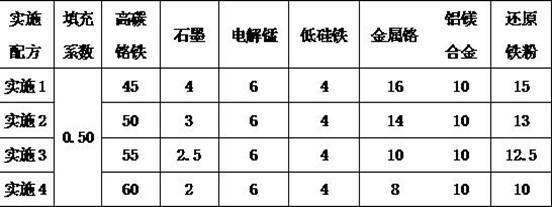

[0015] Embodiment 1-4 Preparation of high chromium cast iron open arc surfacing welding flux-cored wire of the present invention

[0016] The outer steel strip of the welding wire is a low-carbon cold-rolled steel strip with a width of 16mm and a thickness of 0.30mm; its chemical composition is shown in Table 1.

[0017] Table 1. Chemical composition of low-carbon cold-rolled steel strip (mass fraction)

[0018] C mn Si S P ≤0.05 0.18-0.26 ≤0.10 ≤0.03 ≤0.03

[0019] Take each raw material powder according to Table 2, mix it evenly, put it into the powder adding device of the flux-cored welding wire forming machine, and add the powder evenly to the flux-cored welding wire that is gradually rolled and formed. Then the wire is drawn into a flux-cored wire with a diameter of 2.4 to 3.2 mm through a wire drawing machine.

[0020]

[0021] Table 2 Formula of powder mass fraction of flux-cored wire for open-arc surfacing welding of high-chromium cast ir...

experiment example 1~4

[0024] Using the flux-cored welding wire prepared in Examples 1-4 of the present invention, a welding machine with a flat characteristic power supply is used to directly carry out surfacing welding, and the surfacing welding current is selected as 400A. It is observed that there are transverse microcracks on the surface of the weld, and the appearance of cracks can reduce the stress generated during the surfacing process and prevent spalling.

experiment example 5~8

[0026] The flux-cored welding wires prepared in Examples 1-4 of the present invention were tested, and the test results are shown in Table 3.

[0027]

[0028] Table 3 Chemical composition (mass fraction) of deposited metal of high chromium cast iron open arc surfacing welding in Examples 1-4

[0029] Average hardness (HRC) C mn Si S P Cr other Implementation 1 60.2 4.88 1.80 1.50 0.014 0.015 25.8 3.0 Implementation 2 60.5 4.90 1.82 1.52 0.012 0.016 26.0 3.0 Implementation 3 60.8 4.92 1.78 1.55 0.015 0.018 26.2 3.0 Implementation 4 61.0 5.00 1.85 1.50 0.013 0.016 26.4 3.0

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com