Wood raw material pre-treatment method

A treatment method and pretreatment technology, applied in the direction of wood impregnation, impregnated wood, wood processing equipment, etc., to achieve the effect of improving internal bonding strength, reducing water consumption and energy consumption, and rapidly popularizing and applying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

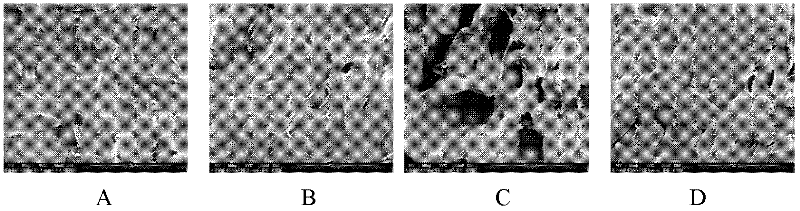

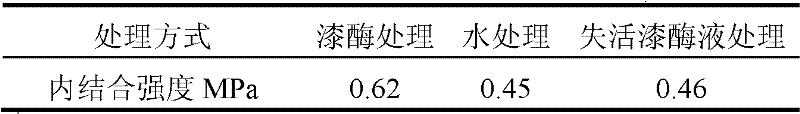

Embodiment 1

[0014] The woody raw material used is poplar wood shavings for particleboard production. Weigh 10 g of poplar wood shavings and place them in a 500 mL beaker, and add 200 g of water to form a shavings-water suspension. The suspension was stirred to pH 4 while adding citric acid-sodium citrate buffer. Add laccase to the above suspension with an enzyme amount of 20U / g woody material, place the above suspension in a water bath at 50°C for 2 hours, filter out the soaking solution after the treatment, and dry the woody material at 60°C for 3 hours . At the same time, make blank, water treatment, and inactivated laccase treatment as controls, observe the surface structure of woody raw materials treated in different ways under an electron microscope, and make particleboard, and measure its internal bonding strength according to the method described in GB / T 17657-1999 , the result is shown below. The results showed that the laccase treatment could loosen the shell-like coating on th...

Embodiment 2

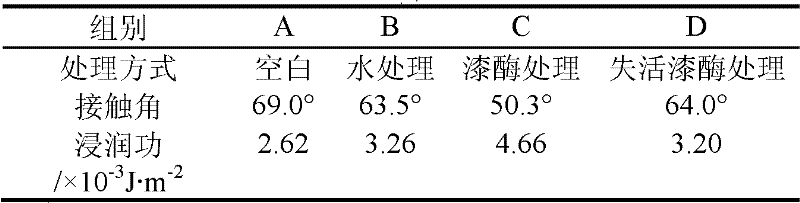

[0018] The woody raw material used is poplar veneer (thickness 1.5cm) used in the production of plywood. Take the poplar veneer and cut it into 3cm×5cm long thin slices. Take 3 pieces (4.6g) and put them in a 250mL beaker, add 100mL of water, and add hydrochloric acid to adjust When the pH reaches 5, add laccase to the above suspension at an enzyme dosage of 30U / g woody material, take it out after incubating at 45°C for 3h, filter out the soaking liquid, and dry the treated poplar veneer in an oven at 70°C for 3h . Simultaneously do the contrast of blank, water treatment, inactivated laccase treatment, adopt OCA40 optical contact angle measuring instrument to carry out surface contact angle measurement to the prepared sample, and make plywood, measure its according to the method described in GB / T 17657-1999 Inner bond strength, the results are shown below.

[0019] Table 2 The wetting angle and wetting work of water on the surface of wood raw materials treated by different me...

Embodiment 3

[0025] The woody material used is poplar solid wood (cut into solid wood blocks with a length of 2.5cm, a width of 2.5cm, and a thickness of 1cm). Take 6 pieces (about 30g) of the solid wood blocks, put them in a 500mL beaker, add 200mL of water, and add dilute sulfuric acid to adjust the pH to 3.5. Add laccase to the above soaking solution with an enzyme amount of 20U / g of woody raw materials, and take it out after 2 hours of incubation at 50°C. After filtering out the soaking solution, the treated poplar solid wood blocks were dried in an oven at 80°C for 2.5 hours, and at the same time, water treatment and inactivated laccase treatment were used as controls. The obtained four groups of wooden blocks were glued with white latex and then pressed and left for 12 hours. HG / T 2727-95 was used to measure the bonding strength and the average value was obtained. The results are shown below.

[0026] Table 4 Effect of different pretreatment methods on the glue strength of poplar sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com