Microbiological bio-imprinting membrane and preparation method thereof

A technology of bio-imprinting and microorganisms, applied in the direction of layered products, etc., can solve the problems of too large target substances, difficulties in immobilization, and difficulties in microbial bio-imprinting, and achieve the effects of mild deposition conditions, increased biocompatibility, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation steps of graphene:

[0026] 1g natural graphite, 1g NaNO 3 It was mixed with 46 mL of concentrated sulfuric acid (98%) and reacted in an ice-water bath for 4-5 h. Then 6g KMnO 4 Added to the mixture solution while raising the temperature to 35°C and maintaining the reaction temperature, after the reaction was carried out for 2-3h, 90-95mL of H was added 2 O and the temperature was raised to 98 °C, after the reaction was carried out for two hours, 200 mL of warm water, 20 mL of 30% H 2 O 2 , and continue the reaction at room temperature for 1-2h. Always keep stirring during the whole reaction process. The prepared product was filtered, washed with distilled water and dried in an oven at 60° C. for 24-48 h to obtain a yellow solid. After the reaction product was ground into pieces, 0.1 g was weighed and added to 100 mL of H 2 Sonicate in O for 1-2h to obtain a homogeneous mixed solution, add 2-3mL N 2 H 4 Then, it is divided into a reactor and reacted ...

Embodiment 2

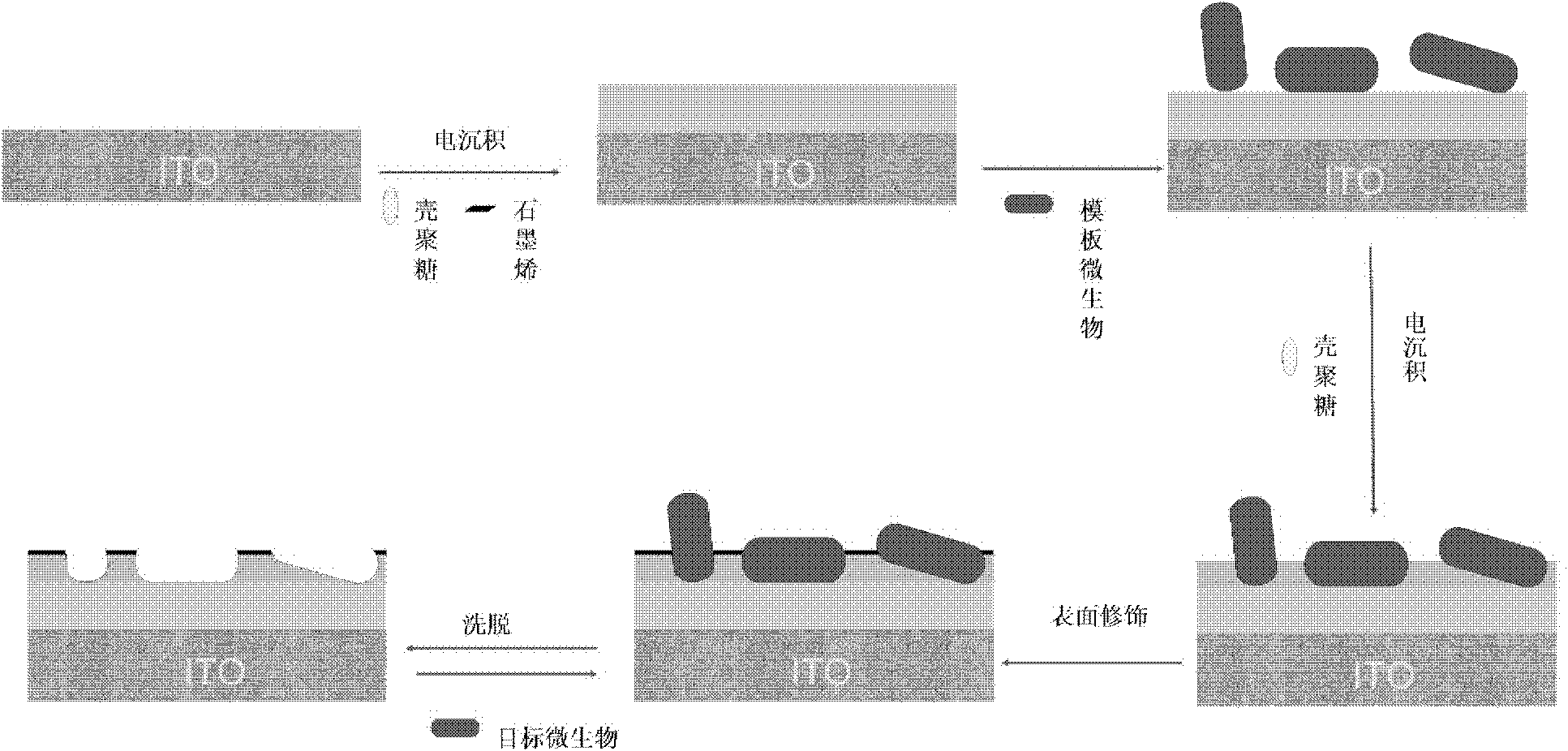

[0028] Preparation steps for microbial bioblotting films (see figure 1 ):

[0029] 1) Cutting and cleaning of ITO electrodes. Cut the ITO electrode into glass pieces of uniform size (1 × 4 cm) with a glass knife, then add absolute ethanol and ultrapure water to the beaker in turn, and ultrasonically treat them for 30 minutes respectively. After taking them out, measure the conductive surface with a multimeter. dry, spare;

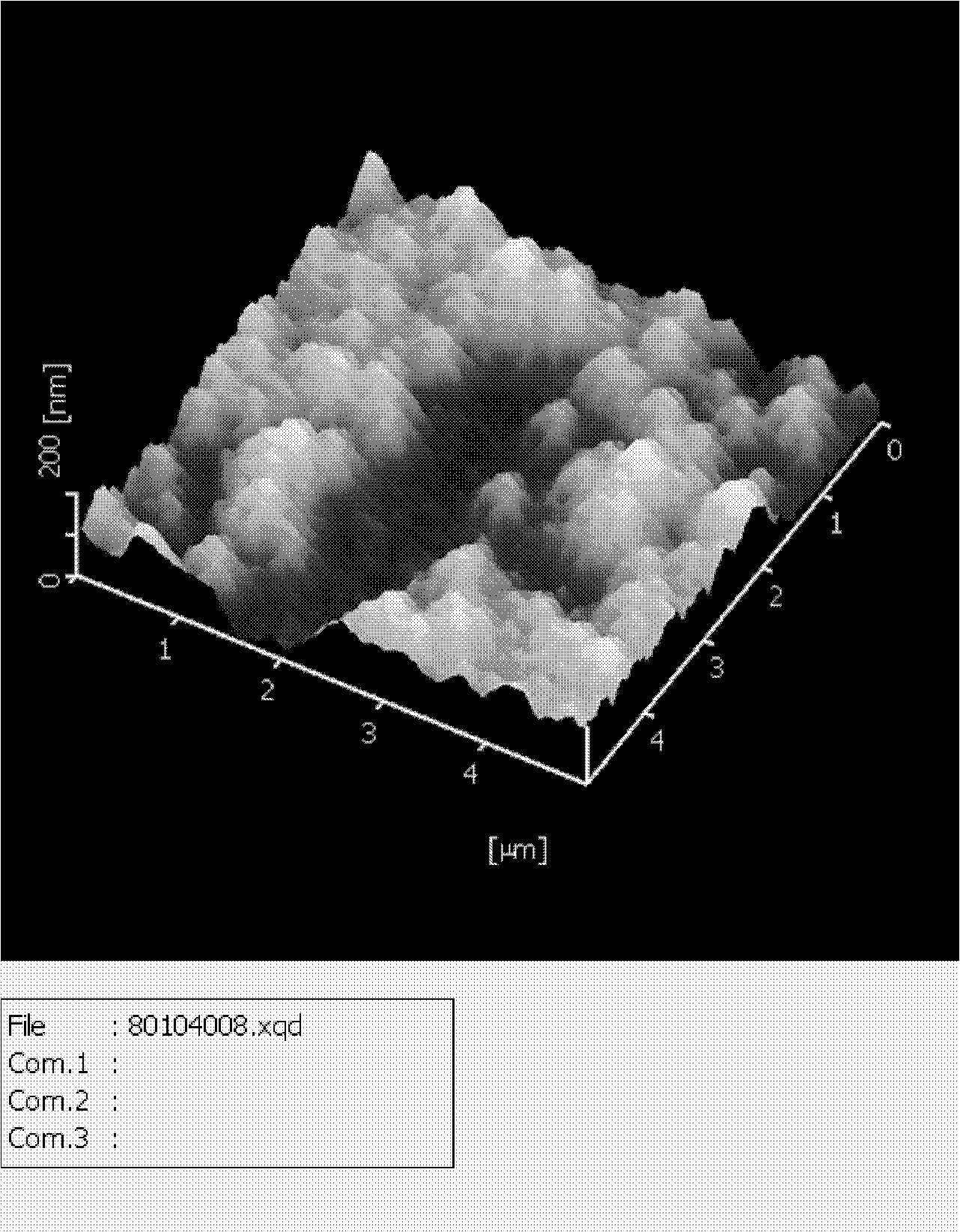

[0030] 2) Deposition of graphene / chitosan composite membrane carrier. The graphene prepared in Example 1 was centrifugally cleaned and added to a chitosan solution with a mass fraction of 0.5% to obtain a graphene-containing concentration of 0.3 mg mL -1 Graphene / chitosan mixture. Using the potentiostatic deposition method, a three-electrode system was used, the platinum wire electrode was used as the counter electrode, the Ag / AgCl electrode was used as the reference electrode, the ITO electrode in step 1) was used as the working electrode, and the depo...

Embodiment 3

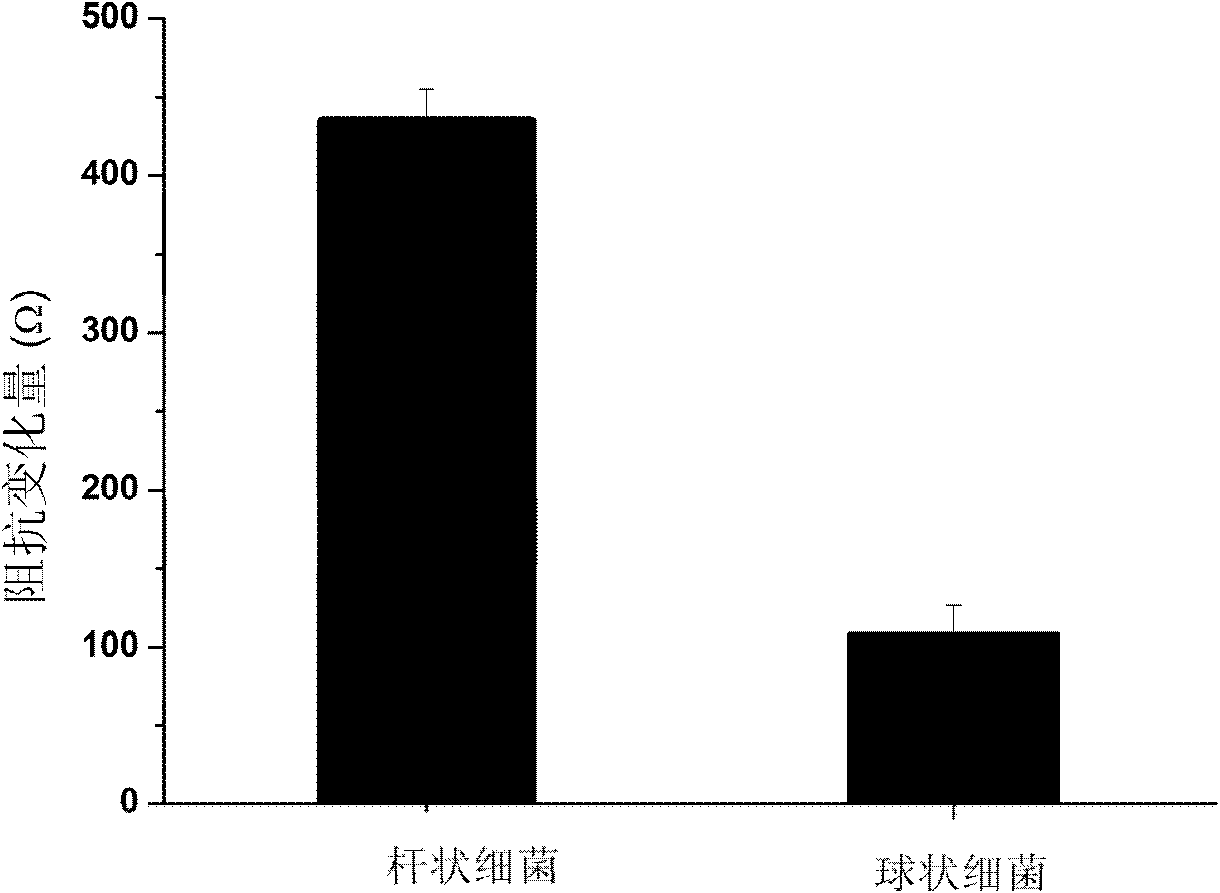

[0036] Selectivity Evaluation of Microbial Bioblot Films:

[0037] The selectivity of the microbial bioimprinted film obtained in Example 2 was evaluated by electrochemical impedance method. A three-electrode system was adopted, the platinum wire electrode was used as the counter electrode, the Ag / AgCl electrode was used as the reference electrode, and the ITO electrode with the microbial bioimprinting film prepared in Example 2) was used as the working electrode. 6 ] 4- / 3- The 0.2M PBS (pH 7.4) buffer was used as the electrolyte. The experimental parameters of electrochemical impedance spectroscopy were set to be measured at open circuit potential, the amplitude of the sine wave was 10mV, and the frequency range was from 0.1Hz to 100kHZ. Rod-shaped bacteria and spherical bacteria of the same concentration were respectively added dropwise to the ITO electrode modified with the recognition site of microbial bioprinting obtained in Example 2. By measuring the electrochemical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com