Method for restraining secondary emission of surface nano-structure of microwave component

A secondary electron emission and nanostructure technology, applied in microstructure technology, microstructure devices, manufacturing of microstructure devices, etc., can solve the problems of high surface resistance, poor conductivity of the coating, difficult to promote, etc. The effect of increasing the discharge threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

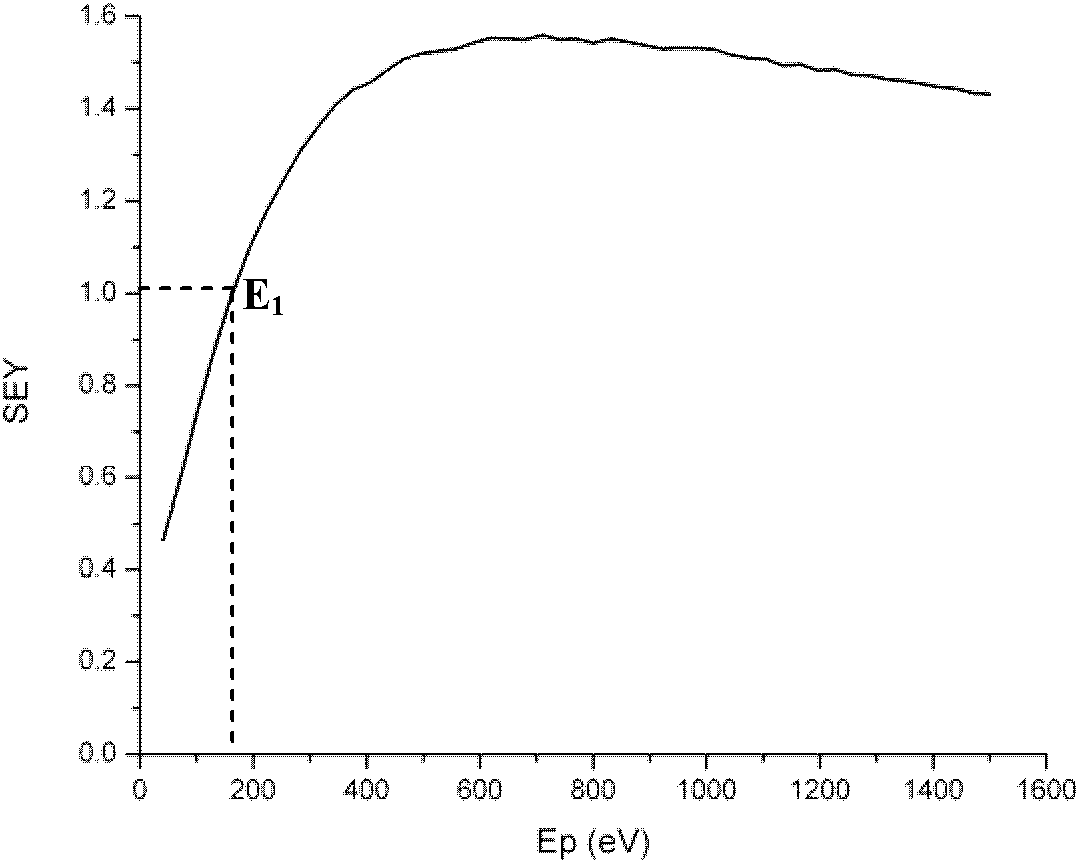

[0027] like figure 1 As shown, the SEY test curve of the electrochemical silver-plated surface on a typical aluminum alloy substrate, the abscissa is the initial energy of the electron incident on the metal surface, when the free electrons in the cavity meet Ep>E under the condition of microwave field acceleration 1 When (E 1 The incident is the electron energy point), and micro-discharge may occur.

[0028] On the basis of obtaining the SEY curve of the surface of the actual microwave component on the satellite, the scale of the nanostructure is limited to below 100nm, which is far smaller than the rough undulation scale of the mechanical processing of the microwave cavity and the subsequent electrochemical surface coating. Therefore, the surface of the actual microwave component is viewed as is an approximately smooth surface.

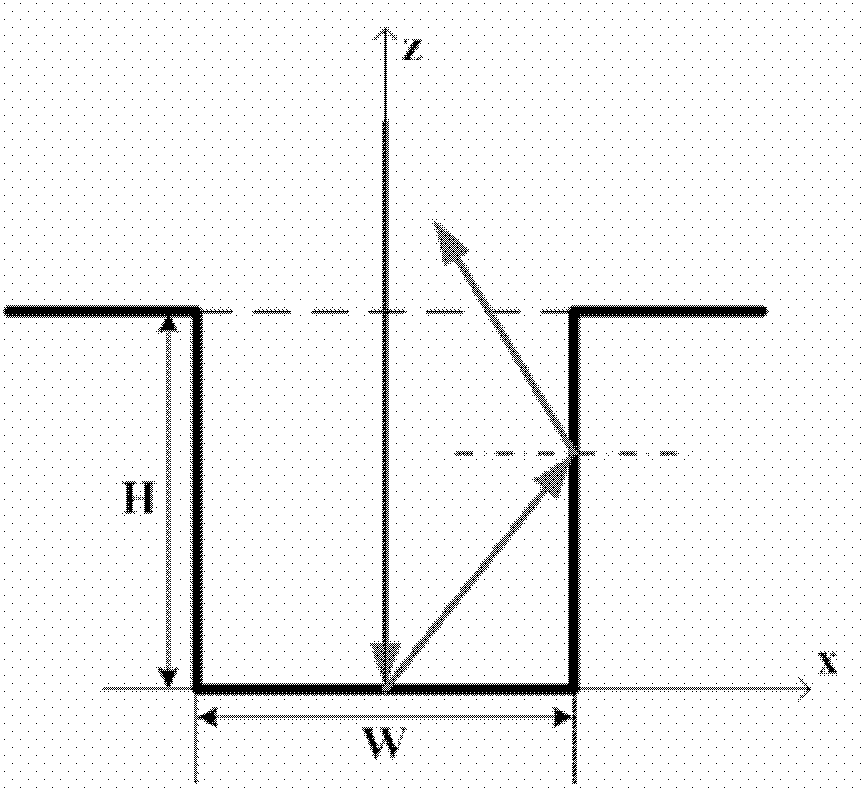

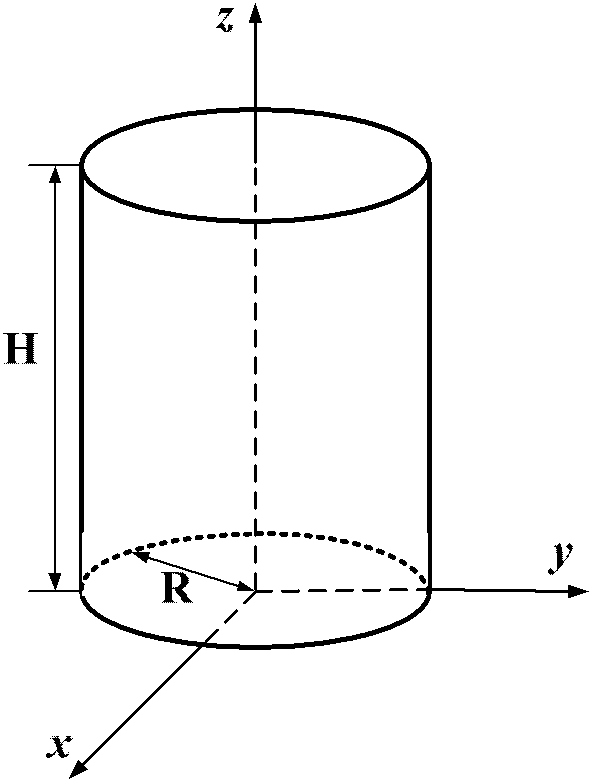

[0029] The Monte-Carlo method (M-C method) is used to simulate the collision, absorption, and collision, absorption, and escape of electrons incid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com