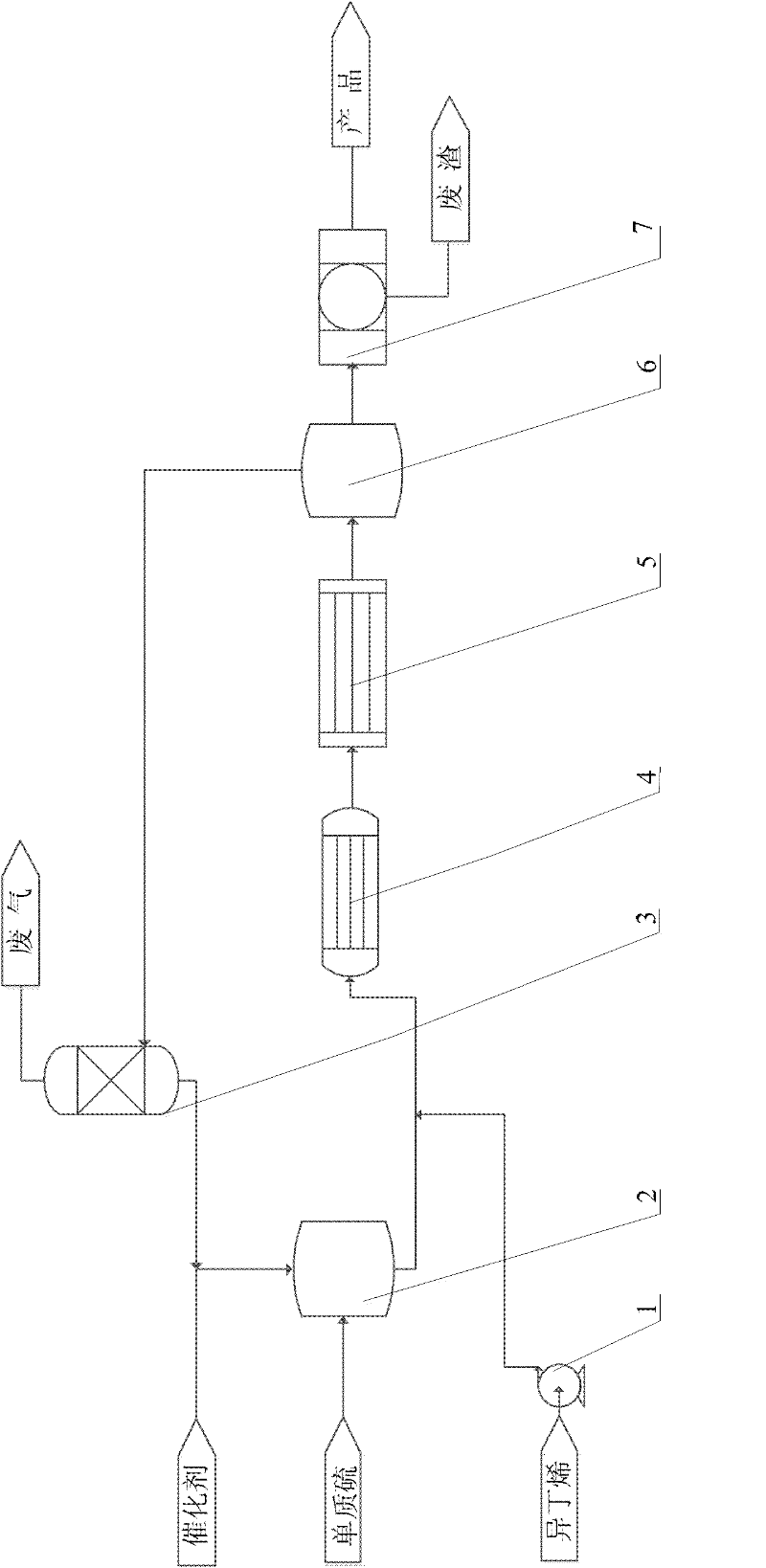

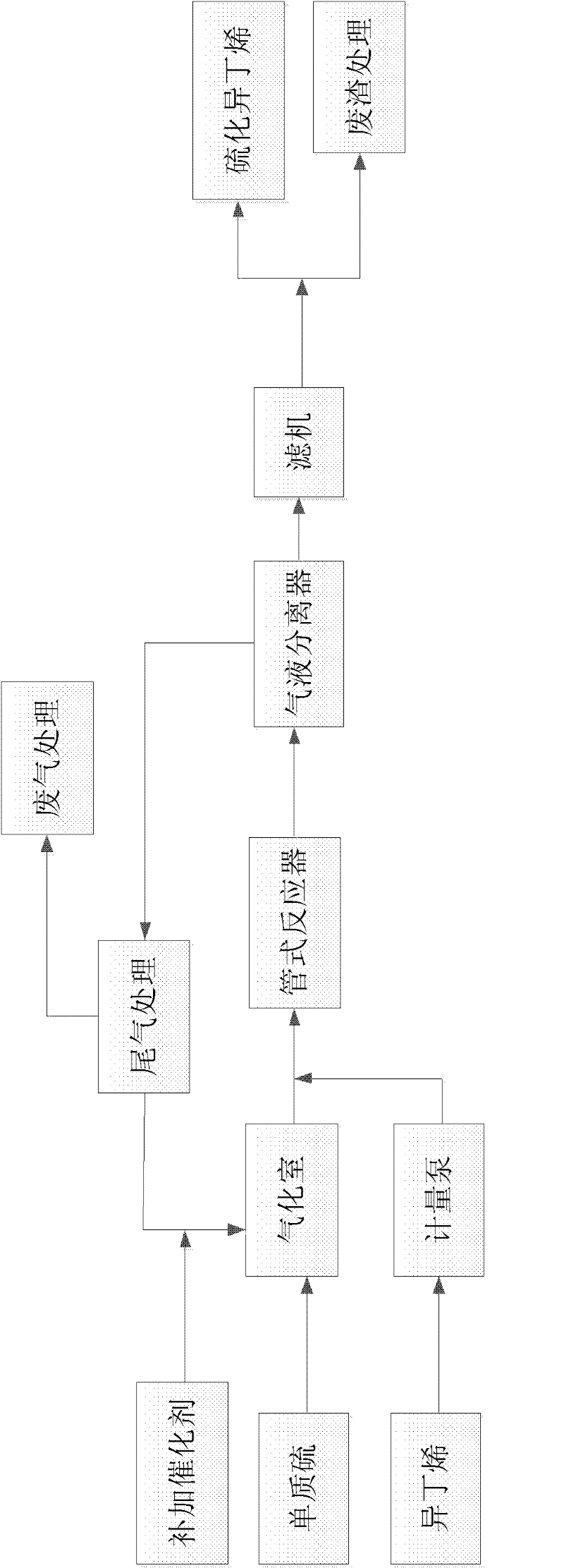

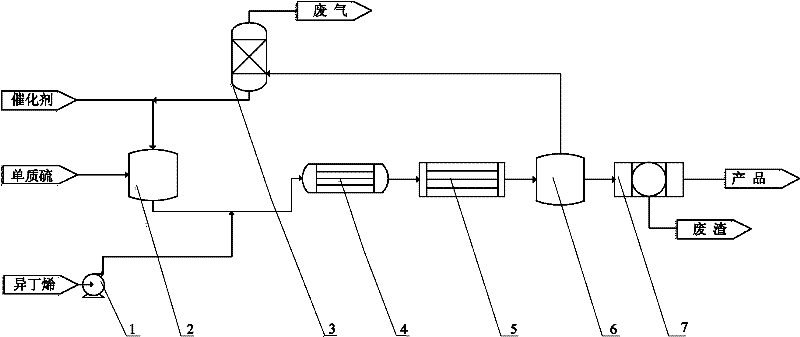

Synthetic technology for sulfurized isobutylene through vapor phase method and device thereof

A technology of sulfurized isobutylene and synthesis process, which is applied in the direction of organic chemistry, which can solve the problems of ineffective recycling of waste gas and waste residue, low reaction conversion rate, and serious environmental pollution, and achieve low production cost, good economic benefits, and high reaction rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) 4 kg of sulfur (i.e. 125 mol of elemental sulfur) and 125 mol of ammonia gas were stirred and mixed for 20 minutes at 450 ° C and 3 MPa to obtain a mixed gas phase stream;

[0034] 2) Feed 100 mol of isobutene gas (the flow rate of isobutene gas is 60mL / min) and mix with the mixed gas phase stream obtained in step 1) to form a gas phase mixture and enter the reactor to react at 460°C and 2MPa for 15min to obtain a reaction product;

[0035] 3) Cool the reaction product obtained in step 2) to 30°C and perform gas-liquid separation. The liquid phase is filtered to obtain 8.1 kg of sulfurized isobutylene product; the gas phase is washed with tail gas to recover the catalyst, and the recovered catalyst is recycled to step 1) for reuse .

Embodiment 2

[0037] 1) Stir and mix 100 g of sulfur (3.125 mol of elemental sulfur) and 1.7 mol of diethylamine at 460° C. and 4 MPa for 10 minutes to obtain a mixed gas phase stream;

[0038] 2) Feed 5 mol of isobutene gas (the flow rate of isobutene gas is 1.5mL / min) and mix with the mixed gas phase stream obtained in step 1) to form a gas phase mixture and enter the reactor to react at 490°C and 3MPa for 12min to obtain the reaction product ;

[0039] 3) Cool the reaction product obtained in step 2) to 40° C. and then perform gas-liquid separation. The liquid phase is filtered to obtain 210 mL of sulfurized isobutylene product; the gas phase is washed with tail gas to recover the catalyst, and the recovered catalyst is recycled to step 1) for reuse.

Embodiment 3

[0041] 1) Stir and mix 100 g of sulfur (ie, 3.125 mol of elemental sulfur) and 3 mol of monomethylamine at 500° C. and 5 MPa for 15 minutes to obtain a mixed gas phase stream;

[0042] 2) Feed 5 mol of isobutene gas (the flow rate of isobutene gas is 1.5mL / min) and mix with the mixed gas phase stream obtained in step 1) to form a gas phase mixture and enter the reactor to react at 450°C and 4MPa for 15min to obtain the reaction product ;

[0043] 3) Cool the reaction product obtained in step 2) to 35° C. and then perform gas-liquid separation. The liquid phase is filtered to obtain 205 mL of sulfurized isobutylene product; the gas phase is washed with tail gas to recover the catalyst, and the recovered catalyst is recycled to step 1) for reuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com