High-strength laminated fire-retarding conveyer belt coating rubber, and preparation method thereof

A covering layer and conveyor belt technology, which is applied in the field of high-strength laminated flame-retardant conveyor belt covering rubber and its preparation, can solve the problems of incapable of high mechanical properties, poor flexibility, poor toughness and softness, etc. It is difficult to balance mechanical strength and excellent flame retardant performance, improve flexibility and strength, and improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

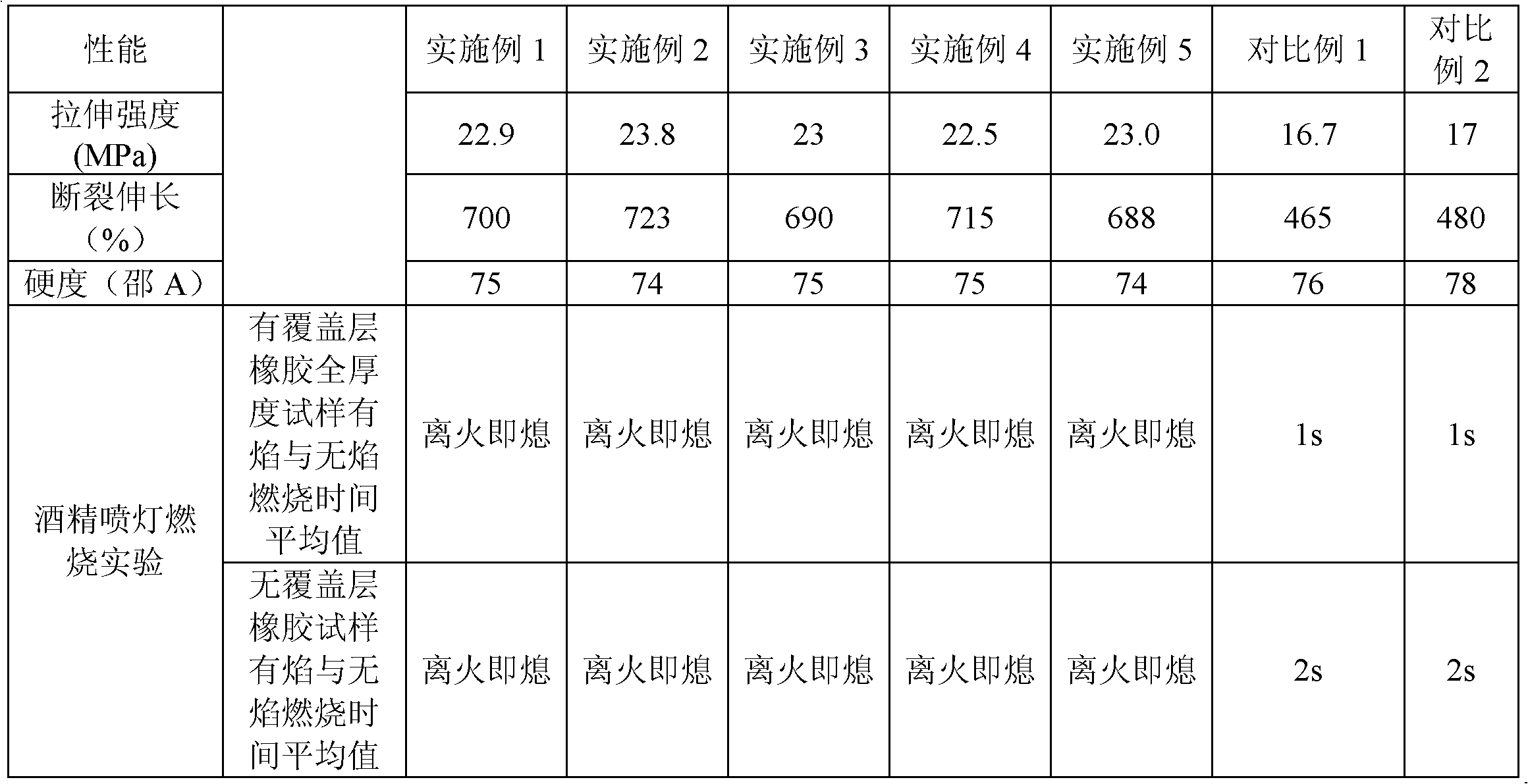

Examples

Embodiment 1

[0033] On the double-roll mill, add 500g styrene-butadiene rubber (commercially available SBR1502) for mastication, and then add metal oxides: 15g nano-zinc oxide, 10g nano-magnesium oxide and 5g stearic acid, anti-aging agent: 2, 2, 4 - Trimethyl-1,2-dihydroquinoline polymer (RD) 5g, N-phenyl-N'-base p-phenylenediamine (4010NA) 10g, flame retardant: chlorinated paraffin 150g, dioxygen trioxide Antimony 40g and zinc borate 40g, reinforcing agent: surface modified silicon dioxide 250g, nano-magnesium hydroxide 100g, and finally add vulcanization accelerator 2-mercaptobenzothiazole (M) 10g, N-tert-butyl-2 -5 g of benzothiazole sulfenamide (NS) and 5 g of N-cyclohexyl-2-benzothiazyl sulfenamide (CZ), and 10 g of sulfur as the vulcanizing agent. Mix evenly on an open mill to obtain a cover layer glue; vulcanize the cover layer glue and the adhesive layer on a molded vulcanized plate at 150°C to obtain a product, and its properties are shown in Table 1.

[0034] The high-strength ...

Embodiment 2

[0036] On the double-roll mill, add 400g styrene-butadiene rubber (commercially available SBR1502), 100g cis-butadiene rubber (commercially available BR9000) for mastication, and then add activator metal oxides in sequence: nano-zinc oxide 15g, nano-magnesium oxide 10g and hard Fatty acid 5g, antioxidant: 2,2,4-trimethyl-1,2-dihydroquinoline polymer (RD) 5g, N-phenyl-N'-yl p-phenylenediamine (4010NA) 10g, Flame retardant: 140g chlorinated paraffin, 50g antimony trioxide and 60g zinc borate, reinforcing agent: 275g surface-modified silicon dioxide, 125g nano-magnesium hydroxide, and finally add vulcanization accelerator 2-mercaptobenzothiazole (M) 10g, N-tert-butyl-2-benzothiazolyl sulfenamide (NS) 5g and N-cyclohexyl-2-benzothiazolyl sulfenamide (CZ) 5g, the vulcanizing agent is sulfur 10g. Mix evenly on an open mill to obtain a cover layer rubber, and then vulcanize the cover layer rubber and the adhesive layer on a molded vulcanized board at 150°C to obtain a flame-retardant...

Embodiment 3

[0038] On the double-roll mill, add 300g styrene-butadiene rubber (commercially available SBR1502), 200g natural rubber (commercially available natural rubber 10#) for mastication, and then add activator metal oxides in turn: 20g nano-zinc oxide, 5g nano-magnesium oxide And stearic acid 5g, antioxidant: 2-mercaptobenzimidazole (MB) 5g, N-phenyl-N'-base p-phenylenediamine (4010NA) 10g, flame retardant: chlorinated paraffin 100g, dioxygen trioxide 60g of antimony and 75g of zinc borate, reinforcing agent: 275g of surface-modified silicon dioxide, 150g of nano-calcium carbonate, and finally add vulcanization accelerator 2-mercaptobenzothiazole (M) 5g, tetramethylthiuram disulfide (TMTD) 5g and N-cyclohexyl-2-benzothiazolyl sulfenamide (CZ) 5g, the vulcanizing agent is sulfur 10g. Mix evenly on an open mill to obtain a cover layer rubber, and then vulcanize the cover layer rubber and the adhesive layer on a molded vulcanized board at 150°C to obtain a flame-retardant conveyor belt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com