Preparation method of nano epoxy resin composite material

A nano-composite material and epoxy resin technology, applied in the direction of epoxy resin coating, epoxy resin glue, adhesive type, etc., can solve the problems of high cost, high density, and difficult degradation of composite materials, and achieve less pollution, Improve the effect of bending strength and fracture bending deformation, excellent mechanical properties and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of epoxy resin nano composite material, it comprises the steps:

[0030] 1) Pretreatment of raw materials: liquid epoxy resin E51 (epoxy value between 0.48 and 0.52mol / 100g) is vacuum-dried to remove water at 50°C (vacuum degree is -0.1MPa), and the time for vacuum drying to remove water is 120min, until the liquid epoxy resin becomes clear and no bubbles come out;

[0031] Diethylenetriamine (curing agent) is purified by vacuum distillation before use (collecting fractions at about 85-90°C under a vacuum of -0.098MPa), so that the purity of the curing agent is greater than or equal to 95wt%;

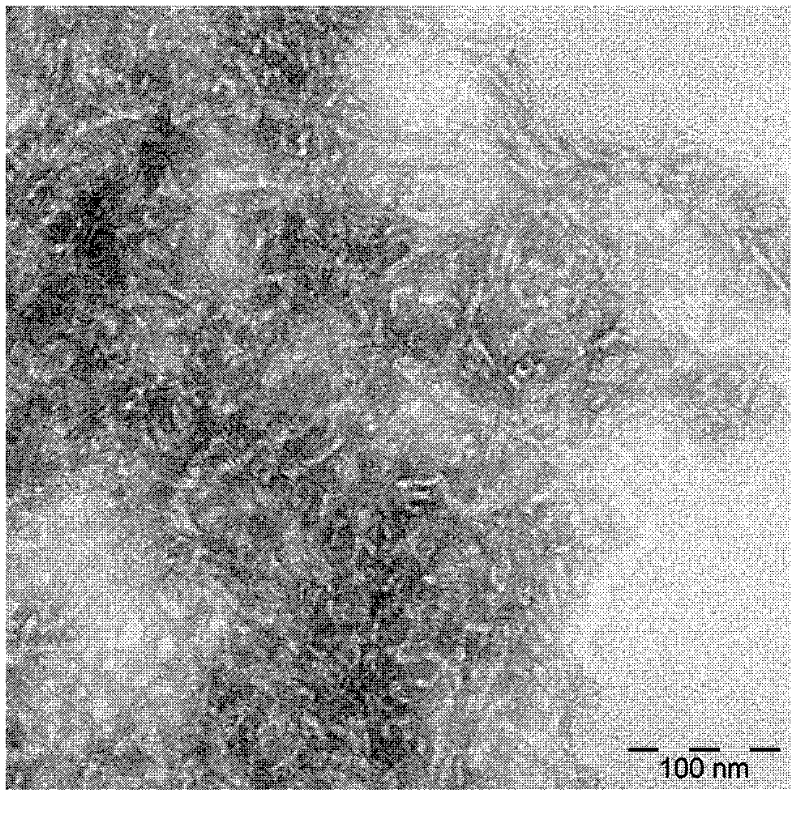

[0032] 2) Extraction of starch nanocrystals through sulfuric acid solution: press H 2 SO 4 The proportioning of solution, pea starch, deionized water is 250mL: 36.00g: 100mL, choose 3.16mol / L H 2 SO 4 Solution, pea starch and deionized water, set aside;

[0033] Under the condition of stirring, pea starch was added to the 3.16mol / L H 2 SO 4 solution co...

Embodiment 2

[0041] A preparation method of epoxy resin nano composite material, it comprises the steps:

[0042] 1) Pretreatment of raw materials: Bisphenol A epoxy resin E51 is vacuum-dried at 100°C to remove water (vacuum degree is -0.1MPa), and the time for vacuum drying to remove water is 180min until the liquid epoxy resin becomes clear And no bubbles come out;

[0043] Diethylenetriamine (curing agent) is purified by vacuum distillation before use (collecting fractions at about 85 to 90°C under a vacuum of -0.098MPa), so that the purity of the curing agent is greater than or equal to 95wt%; the curing agent can be diethylenetriamine Any of aliphatic polyamines such as amine, triethylenetetramine, tetraethylenepentamine, or diethylaminopropylamine.

[0044] 2) First prepare 250mL 3.16mol / L H 2 SO 4 solution, and when the temperature of the sulfuric acid solution dropped to room temperature, it was transferred to a 500mL round bottom flask. Take by weighing 36.00g dry pea starch r...

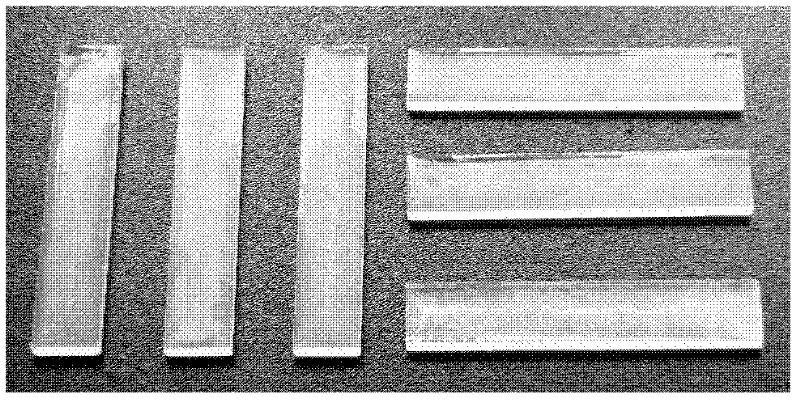

Embodiment 3

[0049] Same as Example 1, change the epoxy resin E51 of the third step {i.e. step 3)}: the mass ratio of starch nanocrystals to 100: 1.5, and change the oil bath temperature, stirring rate, stirring time and ultrasonic time to 60°C respectively , 800rpm, 50min and 30min; the stirring time and vacuum degassing time of the fourth step were changed to 10min and 10min respectively; the degassing time of the fifth step was changed to 10min, curing at room temperature for 3 days, and post-curing at 90°C for 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com