Preparation method of hydrophobic chromic oxide

A technology of chromium trioxide and hydrophobicity, which is applied in the direction of dyeing method, dyeing organic silicon compound treatment, dyeing low molecular organic compound treatment, etc., can solve the problems of non-chromium trioxide hydrophobic modification and relatively few researches, etc. Achieve better coloring effect, improved application, enhanced binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

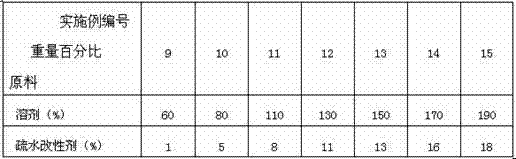

Examples

Embodiment 1

[0019] A preparation method of hydrophobic chromium trioxide, adding 50g of chromium trioxide and 100g of acetone into a 250mL three-necked flask, then placing the three-necked flask in a constant temperature water bath, installing a reflux condensing device, and then heating to 80°C , quickly added 1.0g stearic acid, stirred and reacted for 40 minutes, suction filtered, dried, pulverized, and ground to obtain modified chromium trioxide powder, the activation index of the modified chromium sesquioxide>99%, and the contact angle was The original 32° is increased to 145°, and the chromium trioxide changes from hydrophilicity to hydrophobicity. The obtained hydrophobic chromium oxide was placed in a constant temperature and humidity box (temperature: 25°C, humidity: 80%), and after 30 days, its moisture absorption rate was only 0.1% (18% before modification), and its waterproof performance was improved. Greatly improve. After modification, the polarity of chromium trioxide parti...

Embodiment 2

[0021] A kind of preparation method of hydrophobic chromium trioxide, 50g dichromium trioxide and 100g dehydrated alcohol are added in the there-necked flask of 250mL, then there-necked flask is placed in constant temperature water bath, reflux condensing device is installed, then heated to 90°C, quickly add 1.0g of lauric acid, stir and react for 30min, filter with suction, dry, pulverize, and grind to obtain modified chromium trioxide powder. The activation index of the modified chromium trioxide is >98%, and the contact angle From 32° to 143°, the modified chromium oxide has stronger hydrophobicity. Infrared spectrum research shows that the modified sample is at 1701cm -1 The characteristic absorption peak of the C=O bond in the carboxyl group of lauric acid-COOH disappears at 1639cm -1 The laurate carboxylate anion (CH 3 (CH 2 ) 10 COO-) C=O bond absorption peak at 2923cm -1 and 2853cm -1 CH 3 and CH 2 The characteristic peaks of organic groups such as lauric acid ...

Embodiment 3

[0023] A preparation method of hydrophobic chromium trioxide, 50g of chromium trioxide and 100g of absolute ethanol are added to a 250mL three-necked flask, then the three-necked flask is placed in a constant temperature oil bath, equipped with a reflux condensing device, and then heated To 120°C, quickly add 1.0g of aluminate, stir and react for 30min, filter with suction, dry, pulverize and grind to obtain modified chromium oxide powder, the activation index of the modified chromium oxide is >99%, The contact angle is increased from 32° to 159°, effectively obtaining hydrophobic chromium trioxide powder. Infrared spectrum research shows that the modified sample is at 2919cm -1 and 2851cm -1 CH 3 and CH 2 The characteristic peaks of organic groups, which indicate that the organic matter has been successfully connected to the surface of chromium trioxide particles, and the aluminate coupling agent is chemically bonded on the surface of chromium trioxide to form new chemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com