HB500 (Brinell Hardness 500) wear-resistant steel plate and preparation method thereof

A wear-resistant steel plate, weight percentage technology, applied in the field of steel material manufacturing, can solve the problems of easy growth and coarsening of recrystallized grains, affecting the performance of steel plates, increasing production costs, etc., so as to avoid the growth of matrix grains and eliminate internal Stress and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

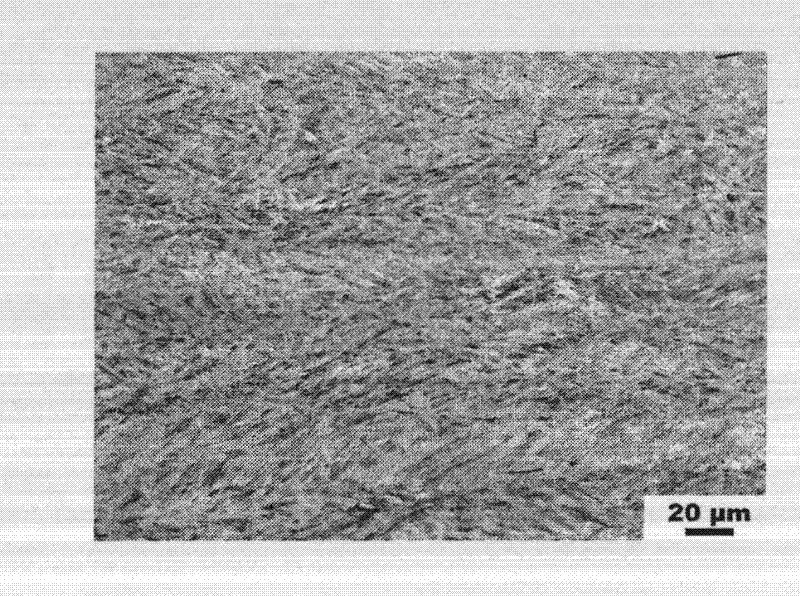

Embodiment 1

[0023] Example 1 The wear-resistant steel plate is composed of the following components (wt%): C: 0.30%, Si: 0.35%, Mn: 0.8%, P: 0.0083%, S: 0.0045%, Cr: 0.6%, Mo: 0.35 %, Nb: 0.028%, V: 0.06%, Ti: 0.016%, B: 0.0025%, and the rest are Fe and unavoidable impurities.

[0024] The mechanical properties of the wear-resistant steel are shown in Table 1, and its production process includes the following steps:

[0025] (1) According to the chemical composition of the above-mentioned wear-resistant steel plate, the raw material is smelted and cast into a slab;

[0026] (2) Heating the above-mentioned slab, the heating temperature is 1200-1250°C, and the holding time is 2h;

[0027] (3) Controlled rolling, rough rolling start temperature ≤ 1000°C, rough rolling finish temperature ≥ 970°C, pass deformation rate 10-30%; finish rolling start temperature 870-900°C, finish rolling temperature The temperature is 790-860°C, the pass deformation rate is 10-30%, the total compression ratio i...

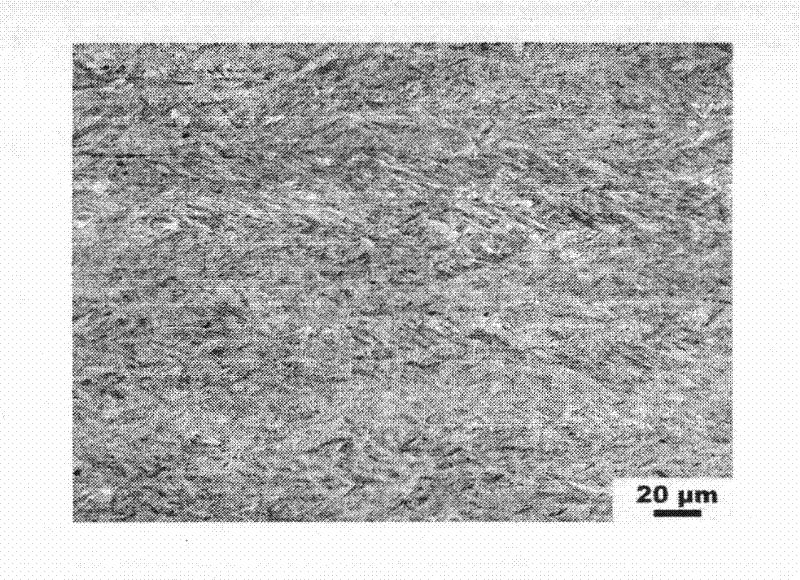

Embodiment 2

[0030] Example 2 The wear-resistant steel plate is composed of the following components (wt%): C: 0.30%, Si: 0.35%, Mn: 0.8%, P: 0.0083%, S: 0.0045%, Cr: 0.6%, Mo: 0.35 %, Nb: 0.028%, V: 0.06%, Ti: 0.016%, B: 0.0025%, and the rest are Fe and unavoidable impurities.

[0031] The mechanical properties of the wear-resistant steel plate are shown in Table 1, and its production process includes the following steps:

[0032] (1) Smelting and casting into a slab according to the weight percentage of the above chemical composition.

[0033] (2) Heating the above-mentioned slab, the heating temperature is 1200-1250°C, and the holding time is 2h;

[0034] (3) Controlled rolling, rough rolling start temperature ≤ 1000°C, rough rolling finish temperature ≥ 970°C, pass deformation rate 10-30%; finish rolling start temperature 870-900°C, finish rolling temperature The temperature is 790-860°C, the pass deformation rate is 10-30%, the total compression ratio is ≥5, and the finished product...

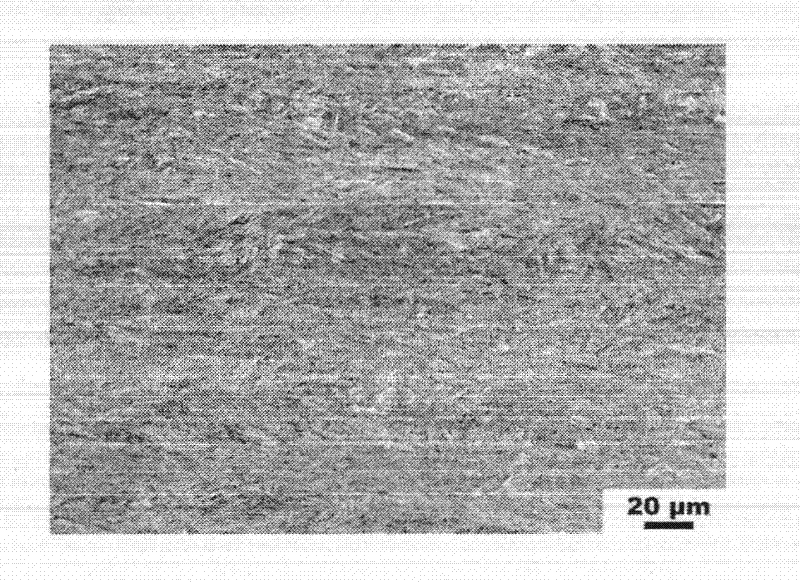

Embodiment 3

[0037] Example 3 The wear-resistant steel plate consists of the following components (wt%): C: 0.30%, Si: 0.35%, Mn: 0.8%, P: 0.0083%, S: 0.0045%, Cr: 0.6%, Mo: 0.35 %, Nb: 0.028%, V: 0.06%, Ti: 0.016%, B: 0.0025%, and the rest are Fe and unavoidable impurities.

[0038] The mechanical properties of the wear-resistant steel plate are shown in Table 1, and its production process includes the following steps:

[0039] (1) Smelting and casting into a slab according to the weight percentage of the above chemical composition.

[0040] (2) Heating the above-mentioned slab, the heating temperature is 1200-1250°C, and the holding time is 2h;

[0041](3) Controlled rolling, rough rolling start temperature ≤ 1000°C, rough rolling finish temperature ≥ 970°C, pass deformation rate 10-30%; finish rolling start temperature 870-900°C, finish rolling temperature The temperature is 790-860°C, the pass deformation rate is 10-30%, the total compression ratio is ≥5, and the finished product is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com