Hawthorn fruit paste product and preparation method thereof

A technology of hawthorn and hawthorn, which is applied in the field of hawthorn and hawthorn products and its preparation, can solve problems such as adverse effects on human health and complicated preparation process, and achieve the effects of avoiding adverse effects, comfortable taste, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

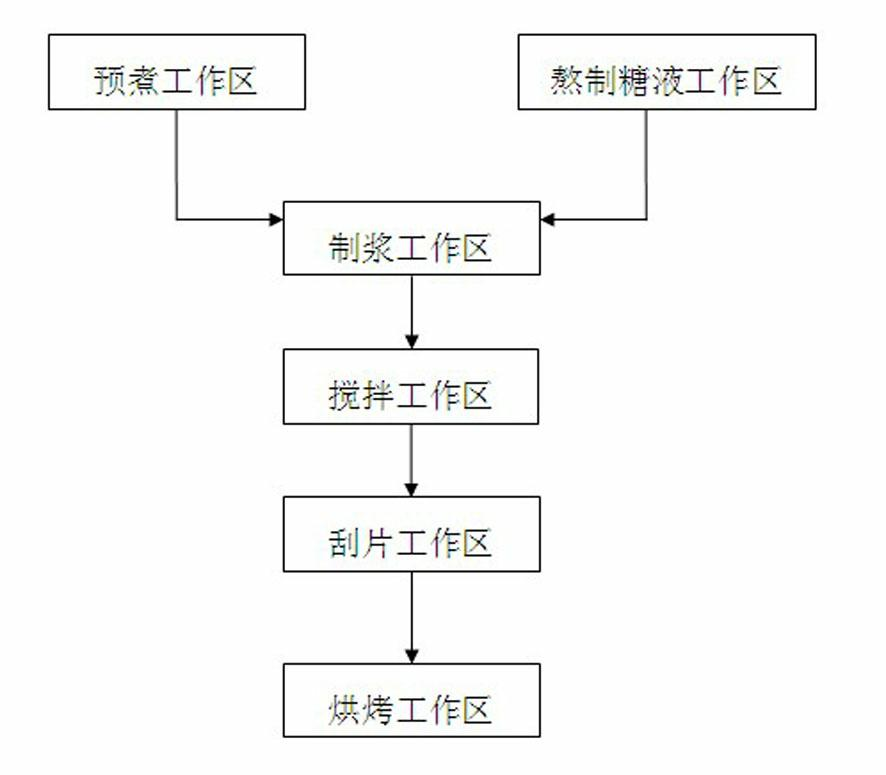

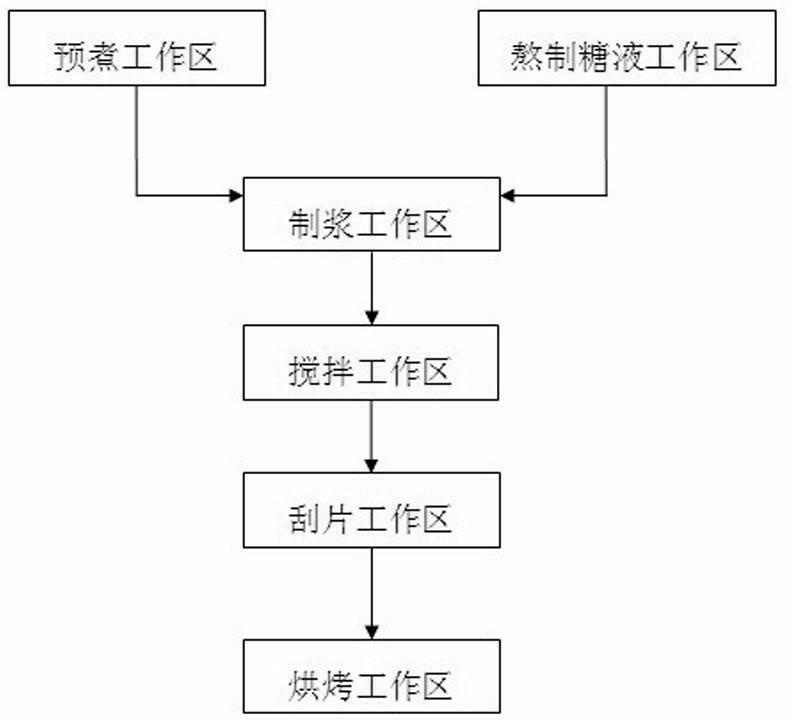

Method used

Image

Examples

Embodiment 1

[0041] A kind of hawthorn fruit peel product, raw materials include: the raw material of described hawthorn fruit peel product includes hawthorn fruit, boiling sugar, water, glucose, natural pigment, coating material; described hawthorn fruit, boiling sugar, The weight ratio of water, glucose, natural pigment and coating material is 40-70:40-55:12-15:8-14:0.05-2:0.05-2.

[0042] The hawthorn fruit is natural pure hawthorn or frozen natural pure hawthorn.

[0043] The quality requirement for described hawthorn fruit is as follows:

[0044] The sugar content of the hawthorn fruit is 20%-30%, the water content is 60%-70%, and the pectin content is 6%-7%;

[0045] The hawthorn fruit is preferably an organically grown hawthorn fruit, and only natural organic fertilizers are used in the planting process to avoid the impact of chemical fertilizers and pesticides on the quality of the hawthorn fruit; the hawthorn fruit can also be wild hawthorn fruit.

[0046] The preferred variety ...

Embodiment 2

[0098] This embodiment is an improvement on the basis of Embodiment 1, and the same parts as Embodiment 1 will not be described again. The raw materials of the hawthorn papaya product include: hawthorn fruit, sugar for boiling, water, glucose, natural pigment, coating material; described hawthorn fruit, sugar for boiling, water, glucose, natural pigment, coating material The weight ratio of materials is 50:40:12:10:0.05:0.05;

[0099] The sugar is a mixture of maltose and white sugar; in the mixture of maltose and white sugar, the weight ratio of white sugar and maltose is 1:1; the natural pigment is radish red;

[0100] The coating material is a powder material, preferably glucose powder.

[0101] Refer to Example 1 for the preparation method of this example.

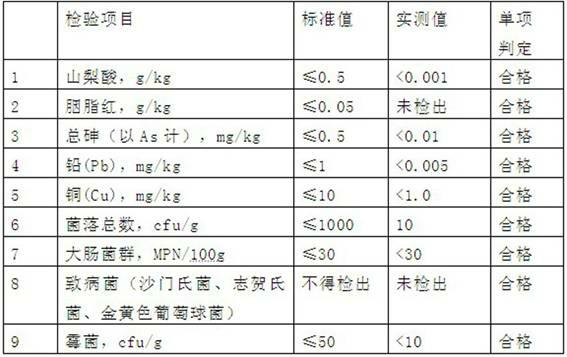

[0102] The detection result of this embodiment is as follows:

[0103] The quality of the hawthorn papaya product in this example meets the requirements of the national standard GB / T 10782 General Rules for Candied ...

Embodiment 3

[0108] This embodiment is an improvement on the basis of Embodiment 1, and the same parts as Embodiment 1 will not be described again. The raw materials of the hawthorn papaya product include: hawthorn fruit, sugar for boiling, water, glucose, natural pigment, coating material; described hawthorn fruit, sugar for boiling, water, glucose, natural pigment, coating material The weight ratio of materials is 60:50:15:10:1:1;

[0109] Described sugar is the mixture of maltose and white sugar; In the mixture of described maltose and white sugar, the weight ratio of white sugar and maltose is 2:1; Described natural pigment is mulberry red;

[0110] The coating material is milk powder;

[0111] Refer to Example 1 for the preparation method of this example.

[0112] The detection result of this embodiment is as follows:

[0113] The quality of the hawthorn papaya product in this example meets the requirements of the national standard GB / T 10782 General Rules for Candied Fruits. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com