Method for preparing functional flavor-developing base material from rice protein

A technology of rice protein and rice protein powder, which is applied in the field of deep processing of rice protein, can solve problems such as difficult control of safety, and achieve the effects of improving human immunity, good anti-oxidation, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

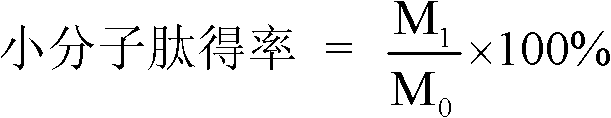

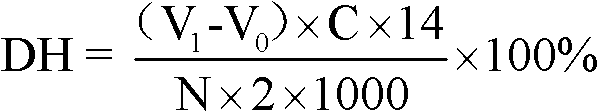

Image

Examples

Embodiment 1

[0030] (1) Rice protein powder (food grade rice protein powder of Anhui Huijia Biotechnology Co., Ltd., protein content 80%) is configured into a protein solution with a concentration of 5% by mass with deionized water, and the The cutting speed disperses the rice protein powder;

[0031] (2) Heat the dispersed rice protein solution to 90°C and keep it for 10 minutes, then cool it to 50°C;

[0032] (3) Use a concentration of 5mol L -1 The pH value of the solution was adjusted to 8.0 with sodium hydroxide, and 2.4L of Novozymes’ alkaline protease Alcalase with 0.5% mass of rice protein powder was added, the enzymolysis temperature was 50°C, and the enzymolysis time was 4 hours; The enzymolysis solution was maintained at 90°C for 10 minutes, and then cooled to 55°C to obtain enzymolysis solution 1;

[0033] (4) Use a concentration of 5mol L -1 hydrochloric acid to adjust the pH value of the solution to 4.0, add 0.01% ascorbic acid of rice protein quality, then add 0.5% acid p...

Embodiment 2

[0044] (1) Rice protein powder (rice dregs of Anhui Huijia Biotechnology Co., Ltd., protein content 50%) is configured into a protein solution with a concentration of 20% by mass with deionized water, and the Dispersion of rice protein powder;

[0045] (2) heating the dispersed rice protein solution to 90°C and keeping it for 30 minutes, then cooling the temperature to 30°C;

[0046] (3) Use a concentration of 10mol L -1 The pH value of the solution was adjusted to 9.0 with sodium hydroxide, and 2.4L of Alcalase Alcalase from Novozymes, which was 2.0% of the mass of rice protein powder, was added. The enzymolysis temperature was 50°C and the enzymolysis time was 10 hours; , the enzymolysis solution was kept at 100°C for 10 minutes, and then cooled to 55°C to obtain enzymolysis solution 1;

[0047] (4) Use a concentration of 5mol L -1 hydrochloric acid to adjust the pH value of the solution to 5.0, add rice protein 0.1% erythorbic acid, add 1% acid protease Protex 26L and 1%...

Embodiment 3

[0050] (1) Rice protein powder (food-grade rice protein powder of Anhui Huijia Biotechnology Co., Ltd., protein content 75%) is configured into a protein solution with a concentration of 10% by mass with deionized water, and the The cutting speed disperses the rice protein powder;

[0051] (2) Heating the dispersed rice protein solution to 100°C and keeping it for 5 minutes, then cooling the temperature to 60°C;

[0052] (3) Use a concentration of 8mol L -1 The pH value of the solution was adjusted to 9.0 with sodium hydroxide, and the alkaline protease Protex-6L of Genencor Co., Ltd. was added with 2.0% of the mass of rice protein powder. The enzymolysis temperature was 60°C and the enzymolysis time was 10 hours; Finally, the enzymolysis solution was kept at 90°C for 20 minutes, and then cooled to 50°C to obtain enzymolysis solution 1;

[0053] (4) with a concentration of 8mol L -1 The hydrochloric acid solution is adjusted to pH value to 5.0, adds rice protein quality 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com