Preparation method of Mn element-doped cyclodextrin polymer material with adsorptive separation function and application thereof

A cyclodextrin polymer, element doping technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of difficult separation and reuse, poor mechanical properties, etc. The effect of regeneration and reuse, good mechanical properties and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

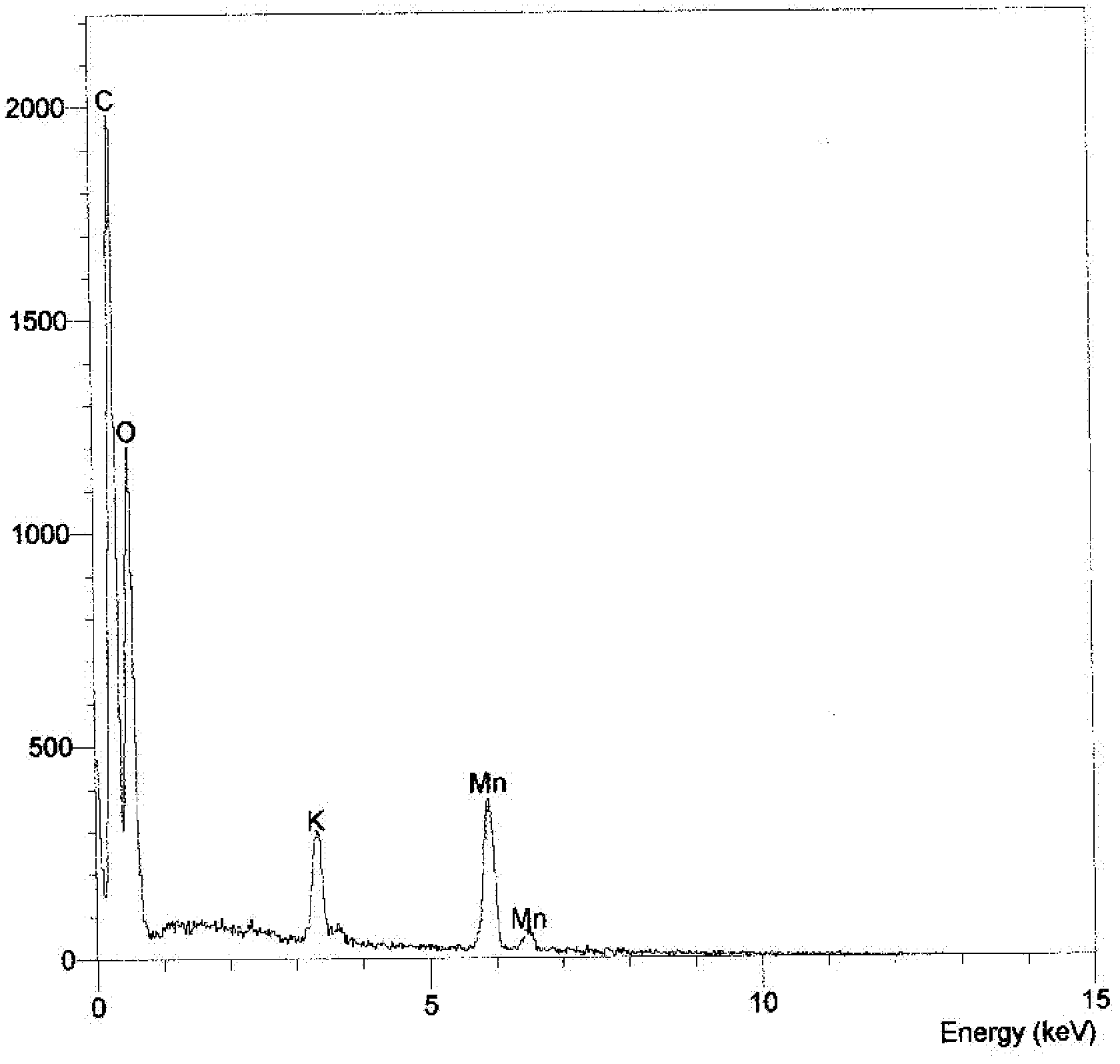

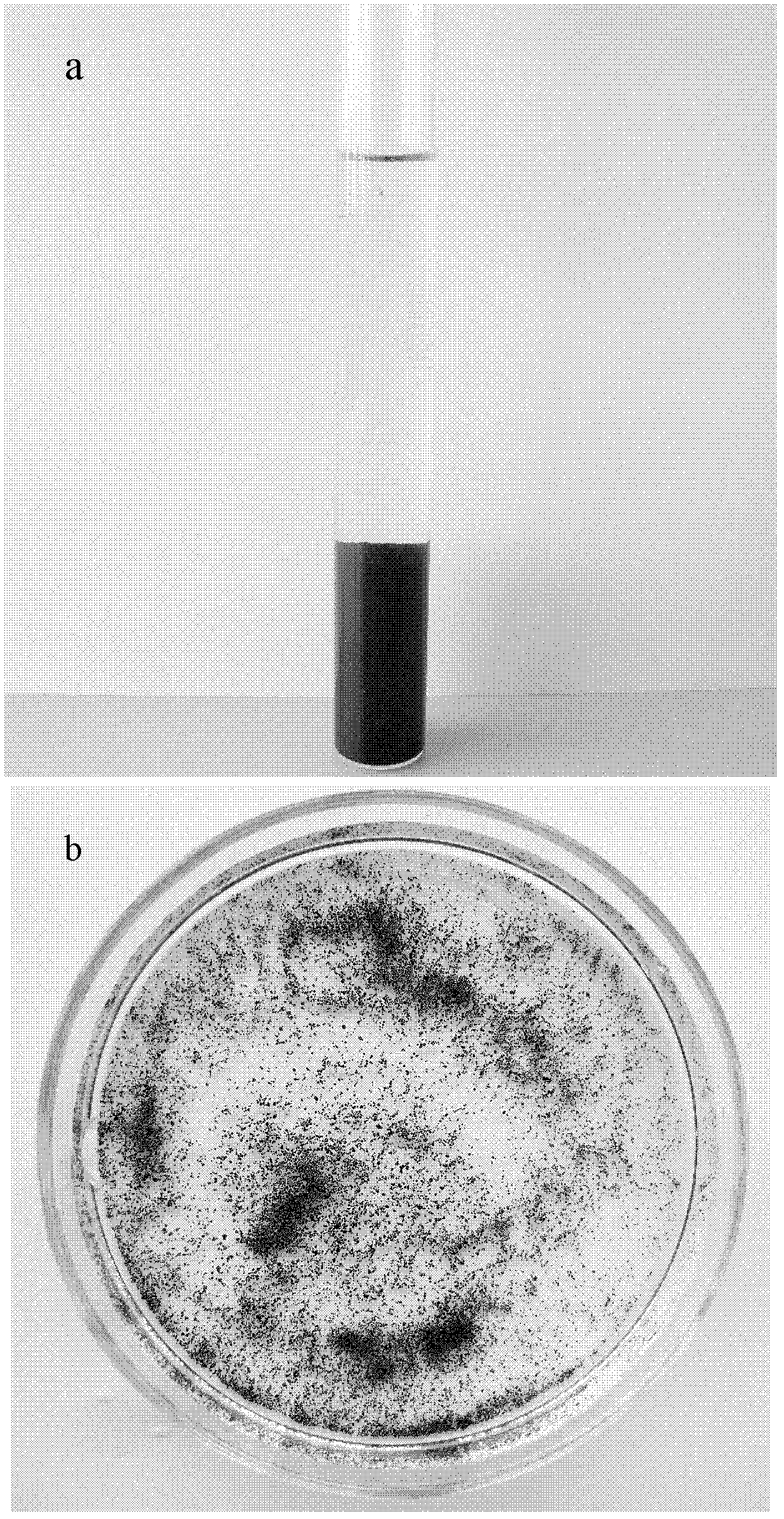

[0022] After recrystallization, 100.0 g of β-CD was weighed and dissolved in 220 g of 16% NaOH solution to obtain a clear slightly yellow solution. At 30° C., 41.0 g of EPI was added dropwise, and after reacting for 1 hour, 44.0 g of 40% NaOH solution was added. At 50°C, add 300ml containing 6.0g dispersant (m span80 :m tween20 =3:1) n-decane solution, after stirring evenly, 80.0 g of EPI was added, and the temperature was raised to 60° C. for 3 h. After the reaction is completed, let it stand for cooling, pour off the supernatant, wash with methanol and deionized water to neutrality, dry in a constant temperature blast drying oven at 70°C, and grind to obtain β-cyclodextrin polymer .

[0023] Weigh 5.0g of β-cyclodextrin high molecular weight polymer in the Erlenmeyer flask, add 100ml of 0.1mol / L KMnO 4 solution, magnetically stirred to disperse, impregnated for 1 h, allowed to stand, filtered, and fully washed with deionized water until the filtrate was clear and neutral...

Embodiment 2

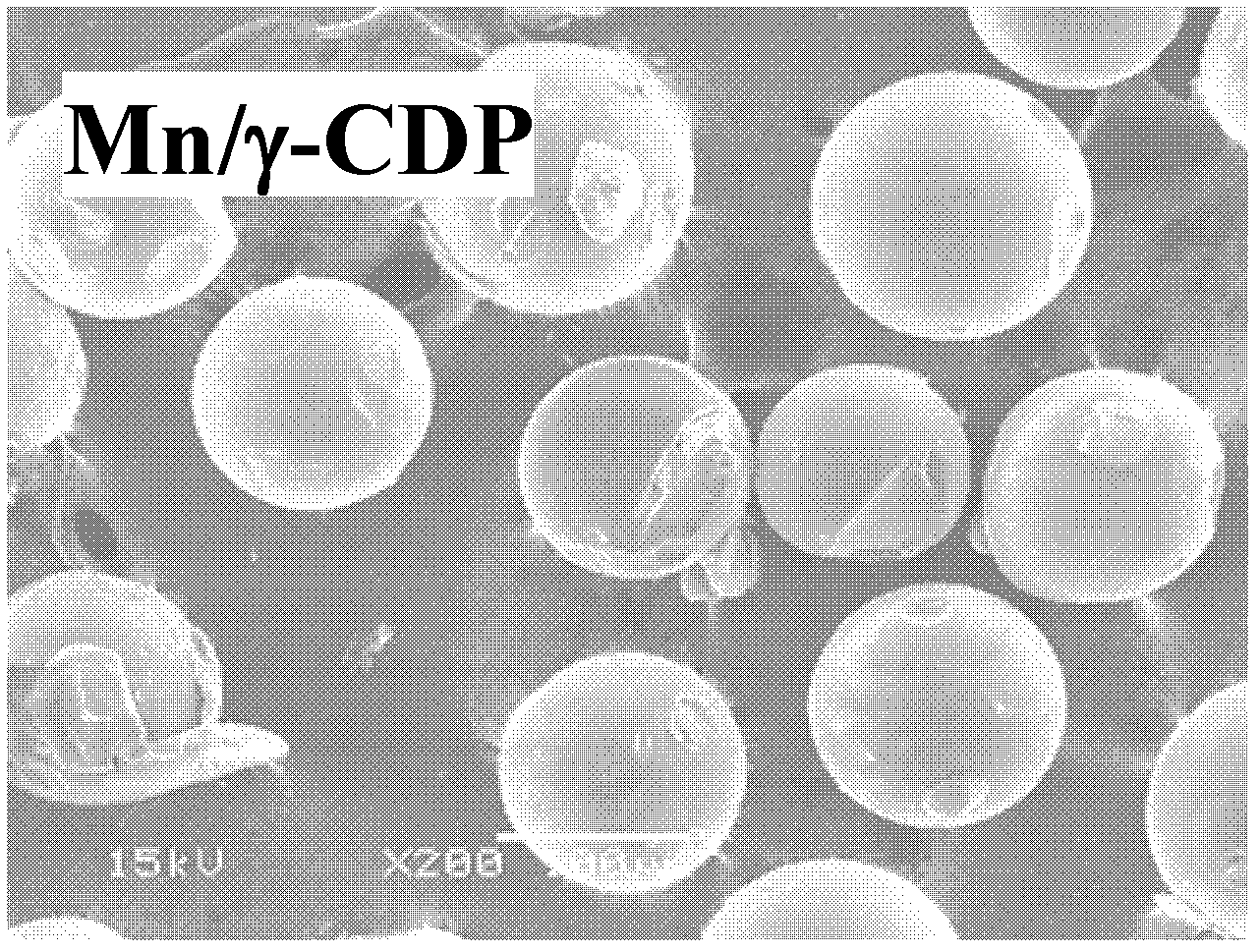

[0025] Weighed 114.3g of γ-CD and dissolved it in 220.0g of 16% NaOH solution to obtain a clear slightly yellow solution. 80.0 g of EPI was added dropwise at 30° C., and after 1.5 h of reaction, 44.0 g of 40% NaOH solution was added. Add 300ml containing 4.0g dispersant (m span80 :m tween20 =3:1) n-decane solution, after stirring evenly, add EPI 41.0g, heat up to 60°C and react for 3.5h. After the reaction is finished, let it stand for cooling, pour off the supernatant, wash with methanol and deionized water in turn until neutral, dry in a constant temperature blast drying oven at 70°C, and grind to obtain γ-cyclodextrin polymer .

[0026] Weigh 5.0g of γ-cyclodextrin high molecular weight polymer in a conical flask, add 100ml of 0.1mol / L KMnO 4 solution, magnetically stirred to disperse, impregnated for 1 h, allowed to stand, filtered, and fully washed with deionized water until the filtrate was clear and neutral, washed with H 2 o 2 Check for no air bubbles. Dry it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com