High-activity iron-based catalysts for coal direct liquefaction and preparation methods for high-activity iron-based catalysts

A technology of direct coal liquefaction and catalyst, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. It can solve the problem that the oil yield needs to be further improved and the requirements for catalyst conditions are high , limited catalyst dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

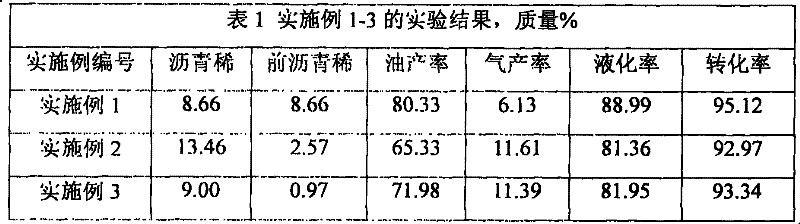

[0035] 36.5g sodium oleate (C 18 H 33 O 2 Na) and 10.8g iron chloride (FeCl 3 ·6H 2 O) Add to the solvent system composed of 140mL n-hexane, 60mL water and 80mL ethanol, stir to make it fully mixed; heat the system to 70℃ for 4h; after that, transfer the solution system to the separatory funnel to make the upper layer oily Add 30 mL of water to the phase, let it stand, and separate the lower water phase, repeat 3 times; dry the oil phase liquid containing iron oleate at 70° C. for 12 hours; finally obtain an oil-soluble iron oleate coal direct liquefaction catalyst.

[0036] Using Xinjiang Jiangjunmiao coal for direct coal liquefaction reaction, mixing 7 parts by weight of the above-mentioned iron oleate catalyst with 30 parts by weight of coal sample, adding 0.3 parts by weight of elemental sulfur and 60 parts by weight of tetralin, passing H 2 , At a temperature of 420°C and a pressure of 6.5MPa, react for 75 minutes; after the reaction, the products are extracted with n-hexane, ...

Embodiment 2

[0038] Add 36 g of naphthenic acid with an average molar mass of 300 and 4.8 g of sodium hydroxide (NaOH) to a solvent system consisting of 140 mL of n-hexane, 60 mL of water, and 80 mL of ethanol, and stir to mix thoroughly; heat the system to 70°C 2h to obtain sodium naphthenate solution; 10.8g ferric chloride (FeCl 3 ·6H 2 O) Add to the sodium naphthenate solution and keep it at 70°C for 4 hours; then, transfer the solution system to a separatory funnel, add 30 mL of water to the upper oil phase, let it stand, and separate the lower water phase. Repeat 3 Second; the oil phase liquid containing iron naphthenate is vacuum dried at 70°C for 12 hours; finally an oil-soluble iron naphthenate coal direct liquefaction catalyst is obtained.

[0039] Using Xinjiang Jiangjunmiao coal for direct coal liquefaction reaction, mixing 14 parts by weight of the above iron naphthenate catalyst with 30 parts by weight of coal sample, adding 0.3 parts by weight of elemental sulfur and 60 parts by ...

Embodiment 3

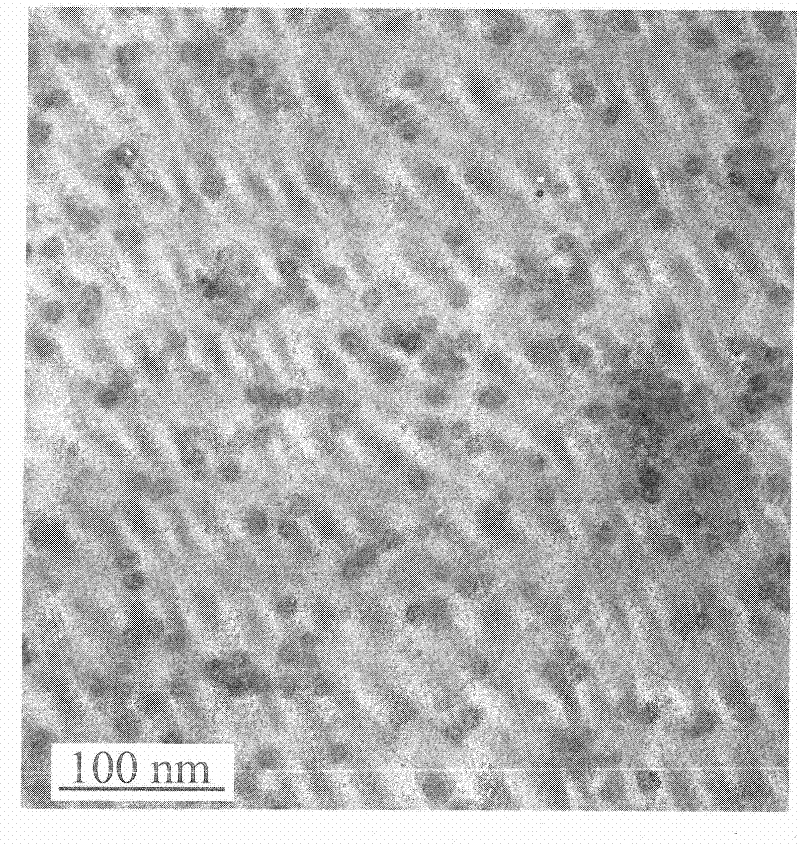

[0041] Mix 70mL of tetrahydronaphthalene and 1mL of oleylamine, stir well for 30min; 2 Under protection, slowly heat the system to 180℃; use a syringe to add 2.4mL Fe(CO) 5 Slowly inject into the system, react at 180℃ for 20min; finally get oil-soluble Fe 3 O 4 Hollow nanospheres are uniformly dispersed in the tetralin solvent system.

[0042] Xinjiang Jiangjunmiao coal is used for direct coal liquefaction reaction. 1 part by weight of the iron-based coal direct liquefaction catalyst is mixed with 25 parts by weight of coal sample, 0.25 parts by weight of elemental sulfur and 50 parts by weight of tetralin are added, and H 2 , At a temperature of 420°C and a pressure of 6.5MPa, react for 75 minutes; after the reaction, the products are extracted with n-hexane, toluene, and tetrahydrofuran through a Soxhlet extractor to obtain oil and n-hexane that are soluble in n-hexane. Asphaltene insoluble in alkanes but soluble in toluene, pre-asphaltene insoluble in toluene but soluble in tetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com