Clean high-value utilization method for preparing fulvic acid and fertilizers by using papermaking black liquor

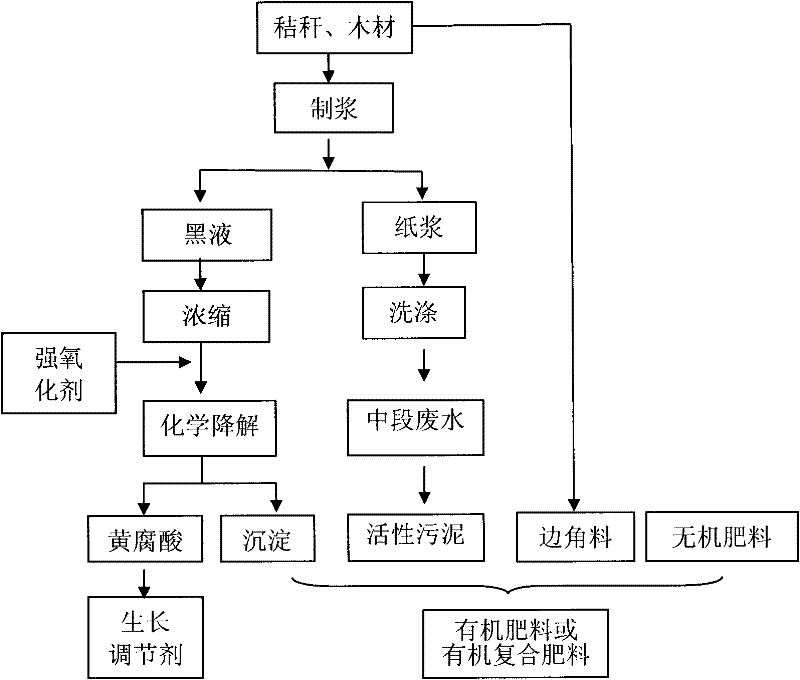

A technology for papermaking black liquor and fulvic acid, applied in chemical instruments and methods, fertilizer mixtures, applications, etc., can solve problems such as a large number of activated sludge, and achieve sustainable development of agriculture, good environmental protection, and no chemical residues. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]The straw is cut into rods, and the leftovers are completely crushed into materials below 5mm. The straw is cooked with sodium hydroxide and the black liquor is squeezed out of the pulp. The dilute black liquor is first evaporated and concentrated to a thick black liquor with a solid content rate of 40%. Add 30% peracetic acid solution to the thick black liquor, the volume ratio of the peracetic acid solution to the thick black liquor is 1:20, mix well, keep stirring and keep warm at 60°C for reaction. After reacting for 50 minutes, phosphoric acid was added to the reaction solution, stirred and mixed to adjust the pH to 4.5. After standing still, the mixture was vacuum filtered to obtain a supernatant, and the precipitate was collected. The content of fulvic acid in the supernatant was 32.4%.

[0042] The activated sludge obtained from the biological treatment of the wastewater in the middle stage of papermaking is fully mixed with the separated sediment and crushed ...

Embodiment 2

[0044] The rice straw is pretreated to obtain neat rod-shaped papermaking raw materials, and the leftovers are completely crushed. The rice straw is subjected to alkaline pulping, and the separated black liquor enters the preparation tank. The black liquor is concentrated and evaporated to a thick black liquor with a solid content of 35%. Add 30% hydrogen peroxide solution to the thick black liquor, the volume ratio of the hydrogen peroxide solution to the thick black liquor is 1:10, mix and react at 70° C. for 1 hour to obtain light brown liquid. Phosphoric acid was added to the liquid to adjust the pH to 5.4. The precipitate in the liquid is separated by high-speed centrifugation. The content of fulvic acid in the clarified liquid was 18.3%.

[0045] The separated sediment is fully mixed with the activated sludge after the biological treatment of the wastewater in the middle stage of papermaking, and the leftovers of rice stalks are fully mixed, and they are naturally sta...

Embodiment 3

[0047] After the cotton stalks are broken into 0.5-2cm pieces by a special grinder, they are sent to the screw feeder through the gas conveying system, and then enter the steaming ball for cooking. Fine dust and leftover scraps generated during raw material handling are collected by cyclone separators.

[0048] Cotton stalks are cooked with potassium hydroxide, and the chemical composition of the black liquor after cooking is: solid content 11.2%, K 2 O 4.7%, N 1.2%. Concentrate and evaporate the black liquor to a thick black liquor with a solid content rate of 30%, and add 1 volume of hydrogen peroxide solution to 8 volumes of the thick black liquor. The mixture was heated to 85°C while stirring the reaction well for 50 minutes. Nitric acid was added to the mixed solution to adjust the pH to 4.2, at which time some precipitation occurred. The solution is vacuum filtered to obtain a clear fulvic acid solution, and the fulvic acid content is 21.4%.

[0049] Fully mix the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com