Conductive polymer film and preparation method thereof

A conductive polymer and film technology, applied in the field of conductive polymer film and its preparation, can solve the problems of complex preparation, low conductivity of conductive polymer film, difficult control of sample shape and size, etc., and achieve simple and convenient preparation method The effect of large-scale production, excellent controllability and wide range of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0027] According to a typical embodiment of the present invention, the method for preparing a conductive polymer film includes the following steps: 1) dissolving the monomer to be polymerized in an organic solvent to obtain solution A; 2) dissolving an oxidant in water to obtain solution B, 3) Mix solution A and solution B to obtain mixture C, freeze mixture C to form a crystal interface, and polymerize the monomer to be polymerized at the crystal interface to obtain a conductive polymer film. The freezing of the mixture C mentioned here means that the mixture C is placed in a constant temperature refrigerator for low-temperature freezing interfacial polymerization. The preparation process causes the organic solvent to crystallize to discharge the monomer to be polymerized under low temperature conditions, and the water crystal to discharge the oxidant ion. The discharged monomer to be polymerized is oxidized by the oxidant ion at the crystal interface formed by the organic solv...

Embodiment 1

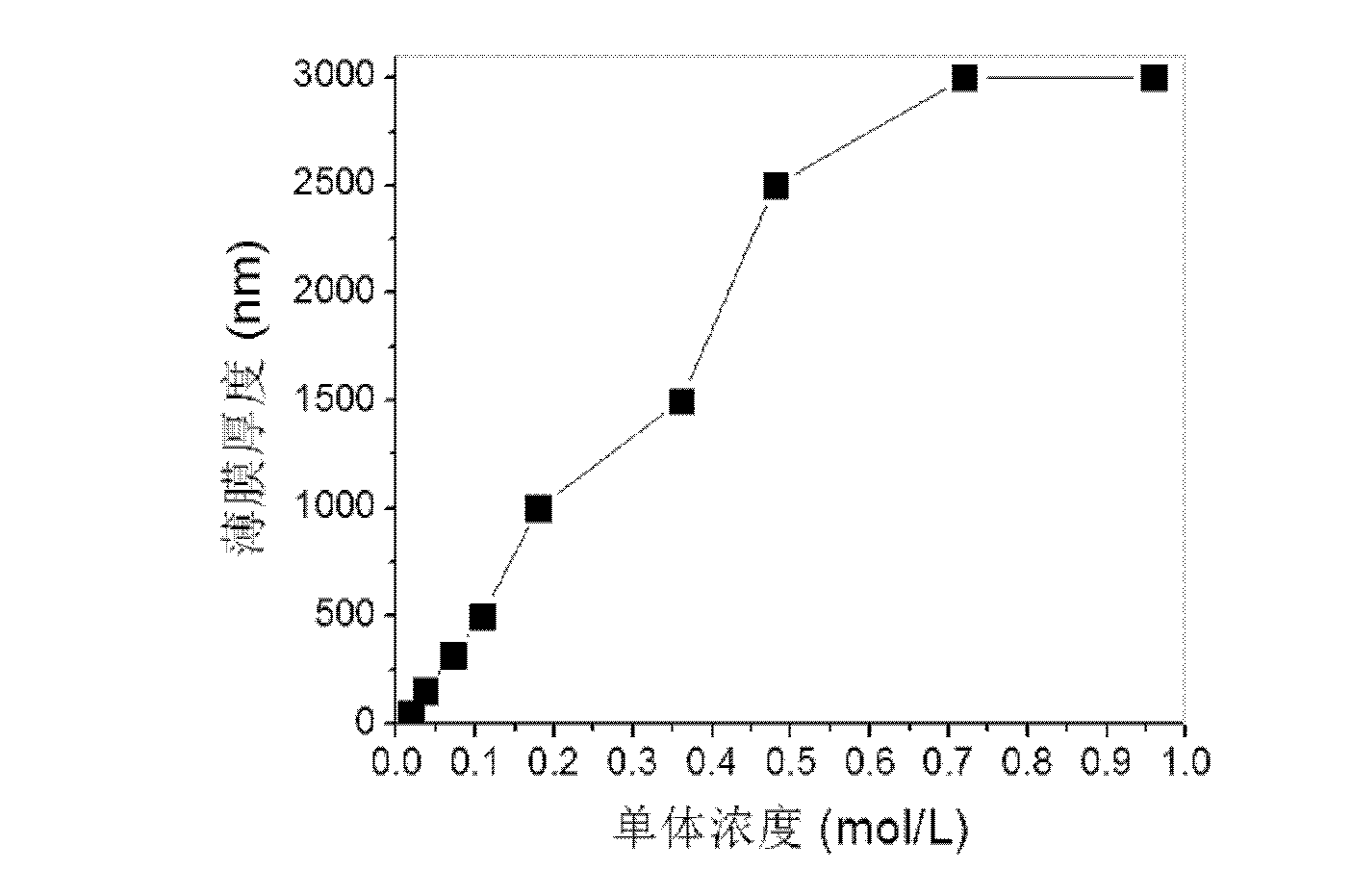

[0036] Preparation of solution A: 0.18mmol of pyrrole monomer was dissolved in 3ml of cyclohexane to obtain a monomer concentration of 0.06mol / L.

[0037] Preparation of solution B: Dissolve 0.18 mmol of ammonium persulfate in 5 ml of deionized water, then add 0.60 mmol of concentrated hydrochloric acid, and mix well to obtain a clear solution.

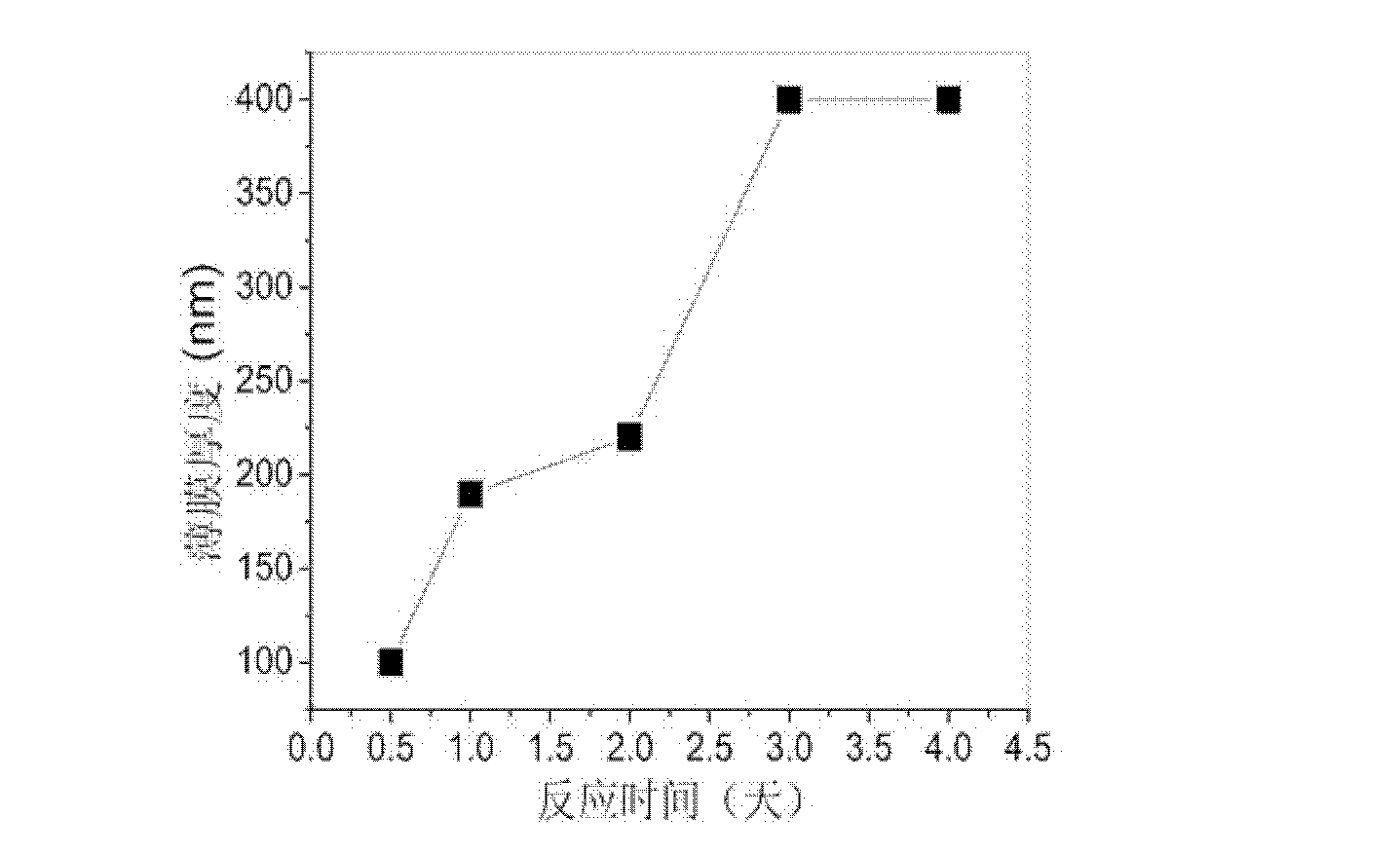

[0038] The solution B was added to the test tube containing the solution A and stirred for a while, and then immediately placed in a constant temperature refrigerator at a temperature of -17° C. for low-temperature freezing interface polymerization. After 12 hours of reaction, the product was repeatedly washed with methanol, acetone, and water, and then filtered. Finally, it was dried in a vacuum oven at 60°C for 24 hours to obtain a bright metallic polypyrrole film with a thickness of 240nm and a conductivity of 580S / cm.

Embodiment 2

[0040] Preparation of solution A: Dissolve 0.72mmol of pyrrole monomer in 3ml of cyclohexane to obtain a monomer concentration of 0.24mol / L.

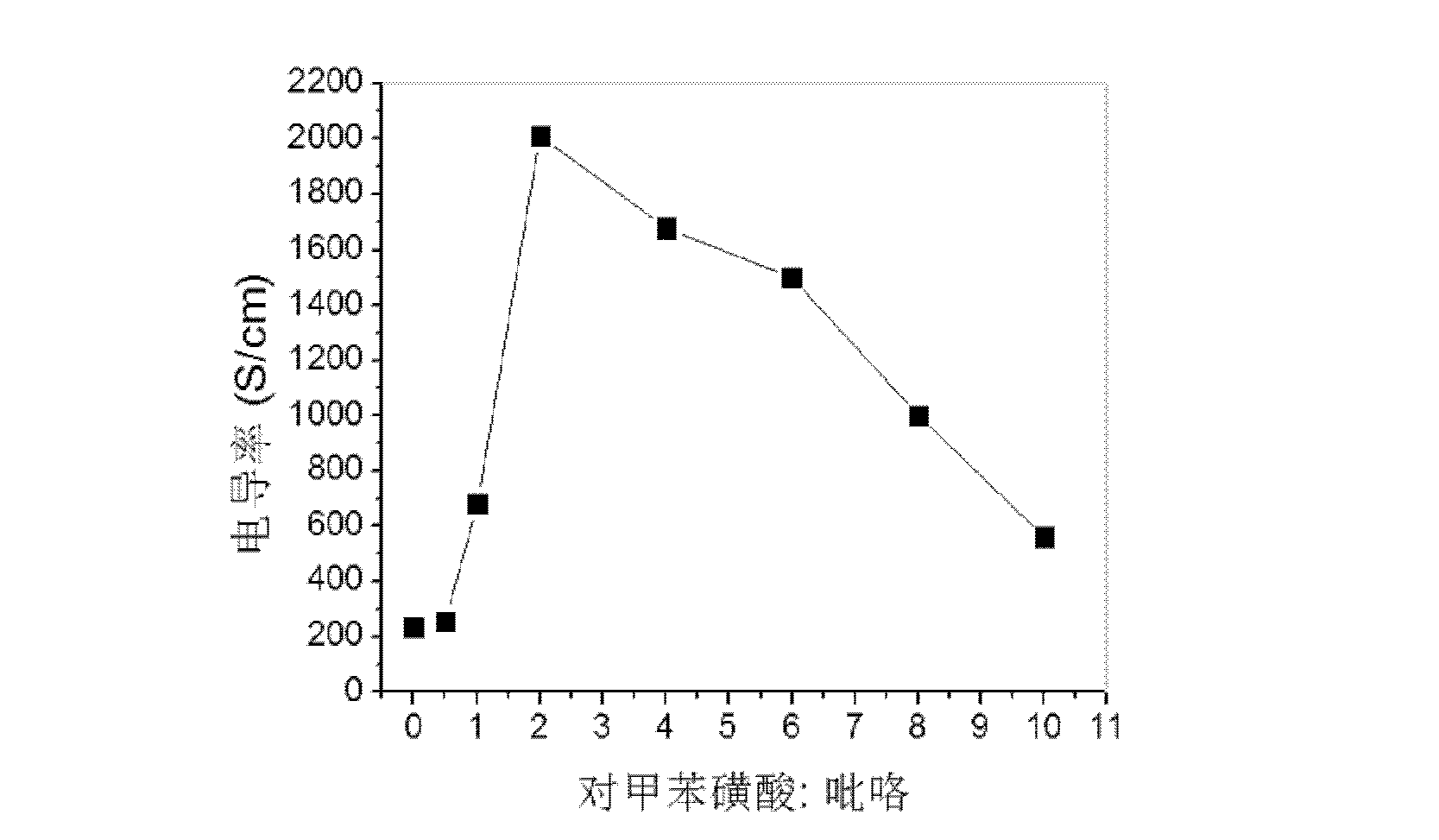

[0041] Preparation of solution B: Dissolve 1.45 mmol of anhydrous ferric chloride in 4 ml of deionized water, then add 2.90 mmol of p-benzoic acid and mix well to obtain a clear solution.

[0042] The solution B was added to the test tube containing the solution A and stirred for a while, and then immediately and immediately quickly frozen in a liquid nitrogen atmosphere. After the freezing was completed, it was placed in a constant temperature refrigerator at a temperature of -17°C for freezing interfacial polymerization. After 24 hours of reaction, the product was repeatedly washed with methanol, acetone, and water, and then suction filtered. Finally, it was dried in a vacuum oven at 60° C. for 24 hours to obtain a black metallic luster polypyrrole film with a thickness of 220 nm and a conductivity of 2010 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com