Titanium dioxide (TiO2) nanotube composite material and method for depositing SnSe/Ag nanoparticles

A technology of titanium dioxide and nanoparticles, applied in the field of nanomaterials, can solve the problems of different sizes of nanoparticles, expensive metals, and uneven distribution, and achieve high electrocatalytic efficiency, shortened reaction time, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Use 800#, 1000#, 2000#, and 2500# sandpaper to polish the surface of the pure Ti sheet until smooth, then clean it with deionized water, ultrasonically dry it with absolute ethanol for 5 minutes, and then dry it for later use

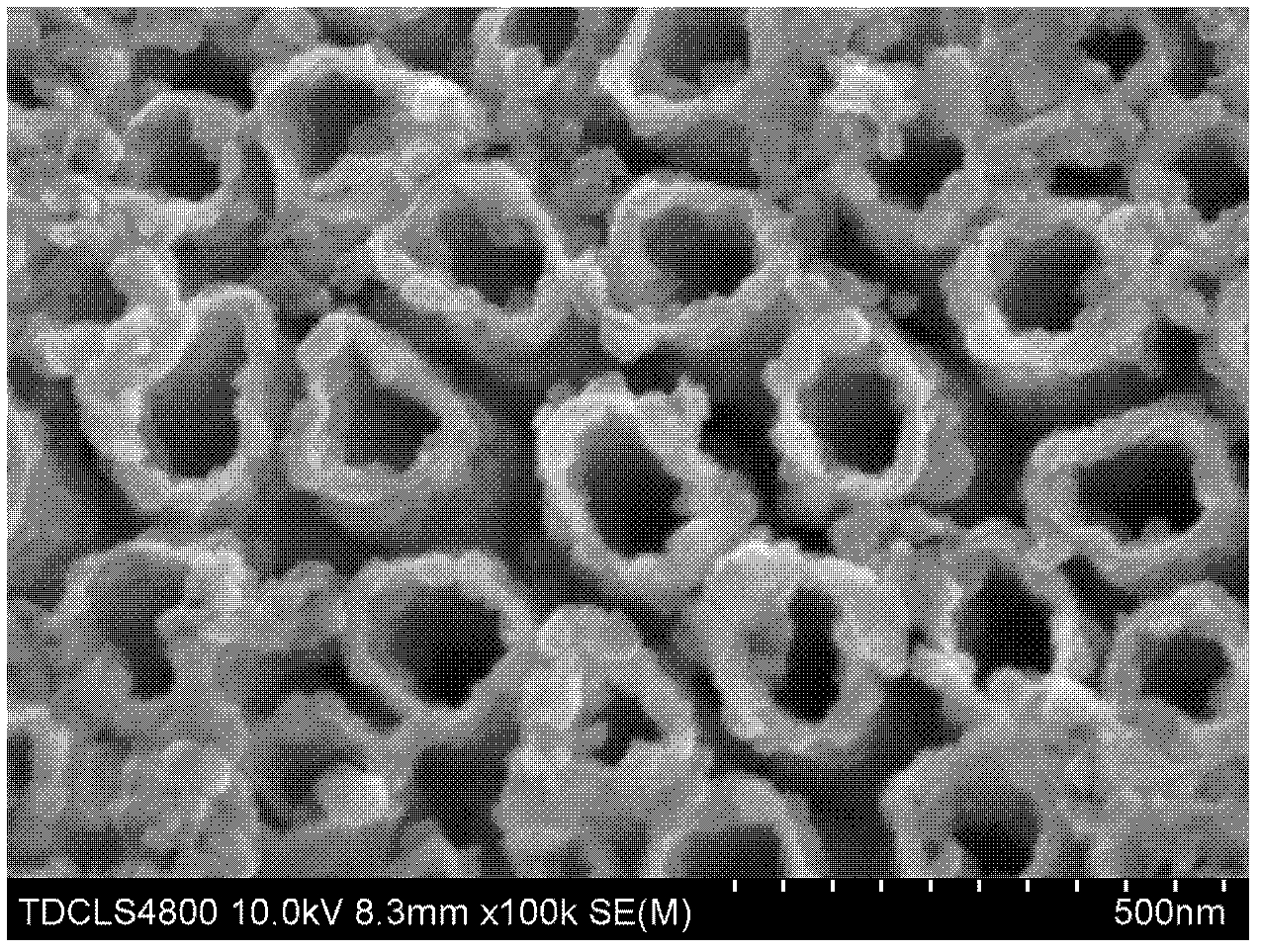

[0031] Titanium dioxide nanotubes were prepared by using a two-electrode system: the anode is a pure titanium sheet, and the cathode is a platinum sheet; in the electrolyte, the volume ratio of glycerol and water is 1, NH 4 The concentration of F is 0.3mol / L, the constant voltage is 30V, and the voltage is applied for 3 hours, that is, the self-assembled TiO is prepared by anodic oxidation. 2 nanotube

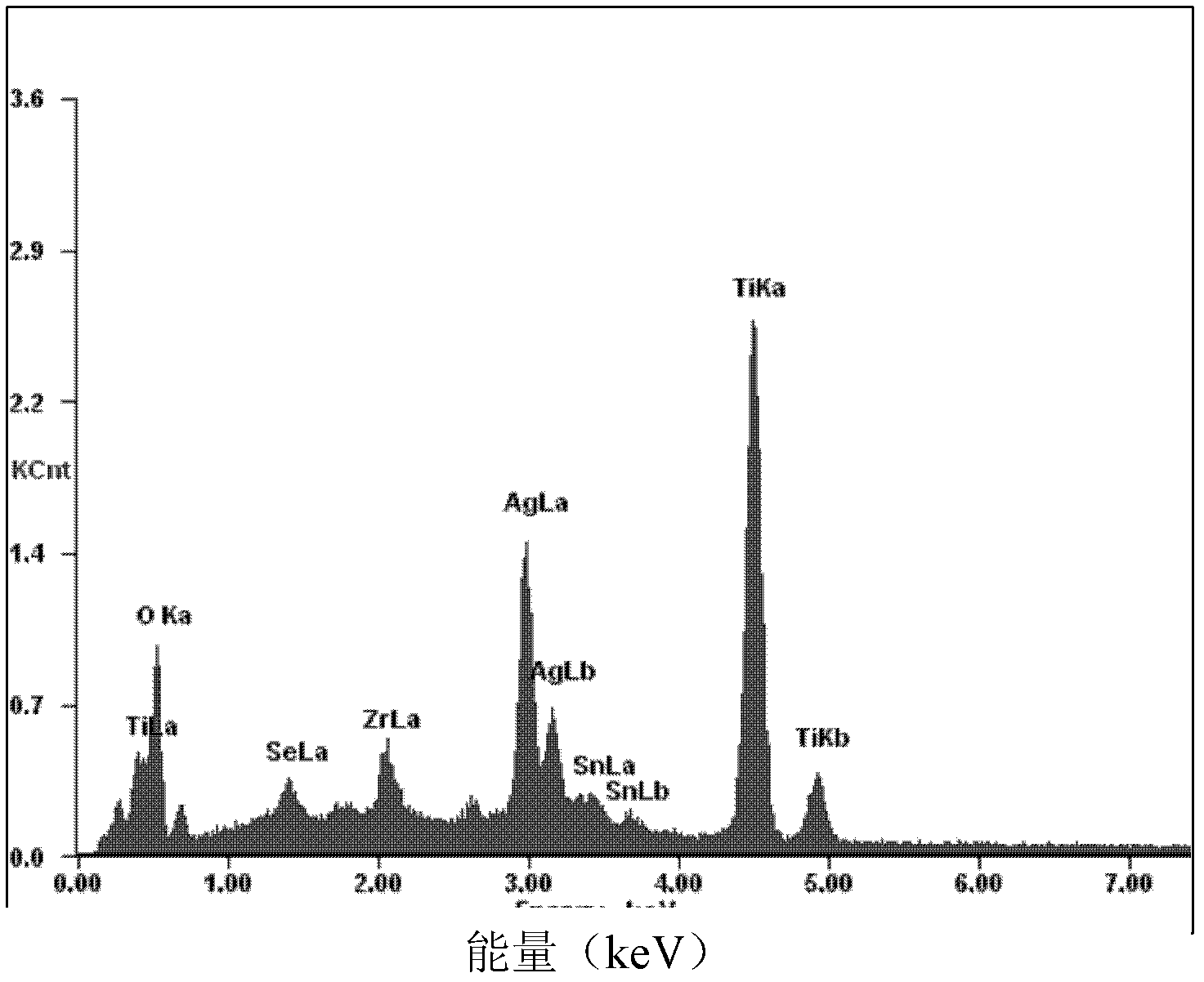

[0032] Will prepare self-assembled TiO 2 Electrochemical deposition of SnSe nanoparticles from pure titanium nanotubes: the TiO to be doped 2 The nanotubes were placed in an electrochemical deposition solution in which SnCl 2 .2H 2 O concentration is 0.05mol / L, SeO 2 Concentration 0.002mol / L, Na 2 CO 3 The concentration is 0.002mol / L, the c...

Embodiment 2

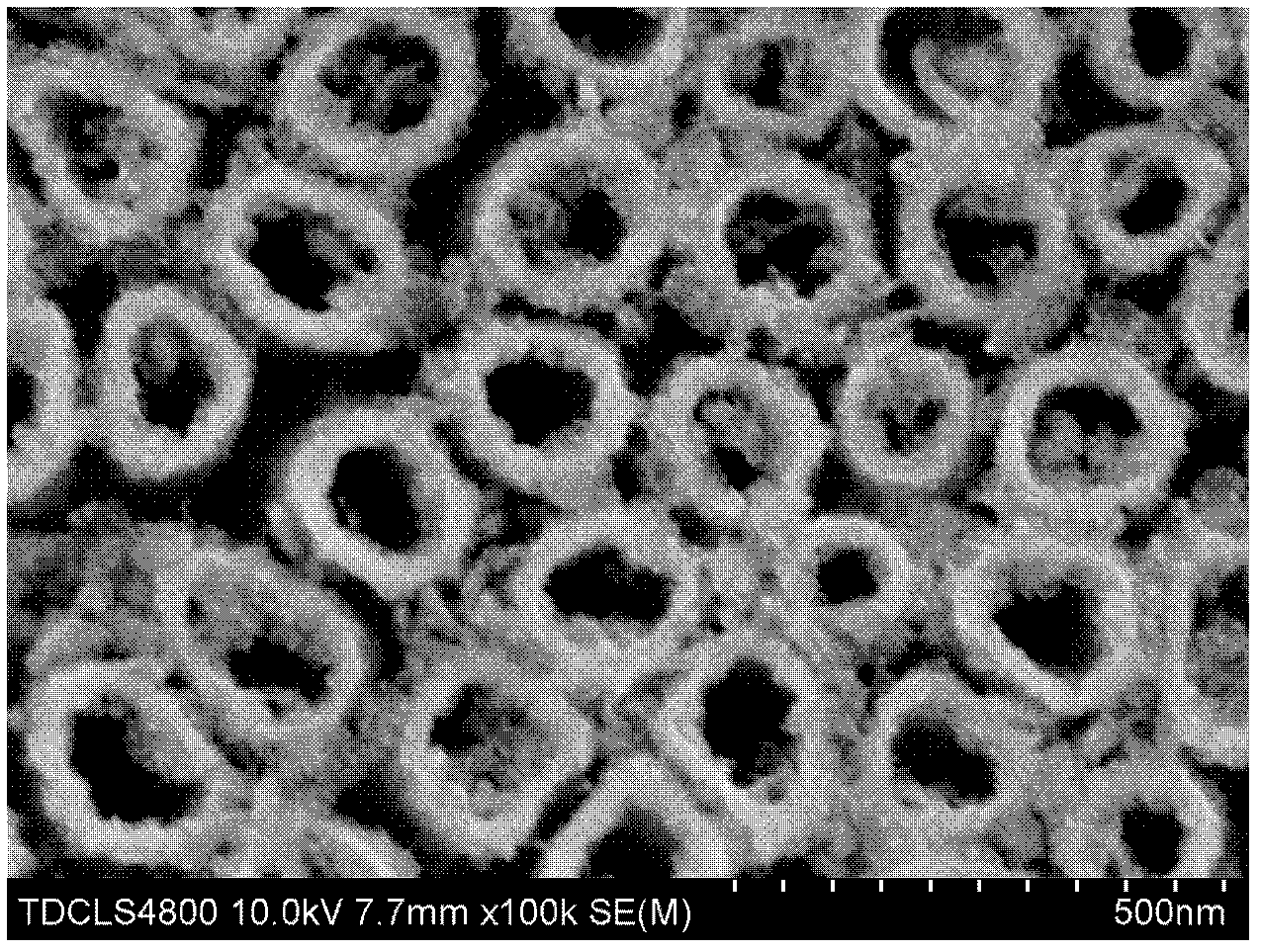

[0035] The surface of the Ti-Zr alloy sheet (the atomic molar ratio of Ti and Zr is 7:3) was polished to smooth with 800#, 1000#, 2000#, 2500# sandpaper respectively, and then cleaned with deionized water and ultrasonically Dry after 10min

[0036] Titanium dioxide nanotubes were prepared by using a two-electrode system: the anode is a titanium alloy sheet, and the cathode is graphite; in the electrolyte, the volume ratio of glycerol and water is 3, NH 4 The concentration of F is 0.5mol / L, the constant voltage is 60V, and the time of applying voltage is 10min, that is, the self-assembled TiO is prepared by anodic oxidation method. 2 nanotube

[0037] Will prepare self-assembled TiO 2 Electrochemical deposition of SnSe nanoparticles on titanium alloy sheets of nanotubes: TiO to be doped 2 The nanotubes were placed in an electrochemical deposition solution in which SnCl 2 .2H 2 O concentration is 0.06mol / L, SeO 2 Concentration 0.0025mol / L, Na 2 CO 3 The concentration is ...

Embodiment 3

[0040] The surface of the Ti-Zr alloy sheet (the atomic molar ratio of Ti and Zr is 8:2) was polished to smooth with 800#, 1000#, 2000#, 2500# sandpaper respectively, and then cleaned with deionized water and ultrasonically Dry after 10min

[0041] A two-electrode system was used to prepare titanium dioxide nanotubes: the anode was a titanium alloy sheet, and the cathode was graphite; in the electrolyte, the volume ratio of glycerol to water was 0.4, and NH 4 The concentration of F is 0.1mol / L, the constant voltage is 10V, and the voltage is applied for 4 hours, that is, the self-assembled TiO is prepared by anodic oxidation. 2 nanotube

[0042] Will prepare self-assembled TiO 2 Electrochemical deposition of SnSe nanoparticles on titanium alloy sheets of nanotubes: TiO to be doped 2 The nanotubes were placed in an electrochemical deposition solution in which SnCl 2 .2H 2 O concentration is 0.045mol / L, SeO 2 Concentration 0.0015mol / L, Na 2 CO 3 The concentration is 0.00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com