Nano-electromechanical resonant sensor based on graphene sheet layer and manufacturing method thereof

A resonant sensor, graphene sheet technology, applied in piezoelectric devices/electrostrictive devices, processes for producing decorative surface effects, piezoelectric/electrostrictive/magnetostrictive devices, etc. Low-pass filtering of olefin resonators, unfavorable large-scale, mass production, complex optical path design, etc., achieve the effect of small quality, elimination of low-pass filtering phenomenon, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

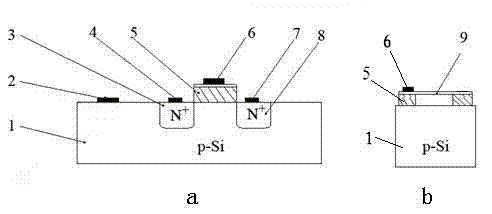

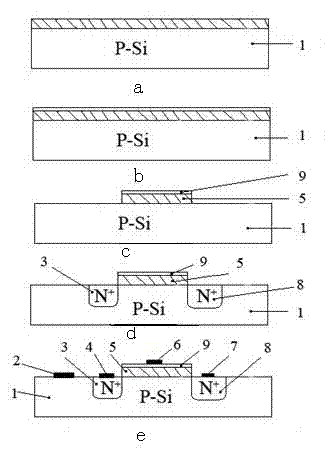

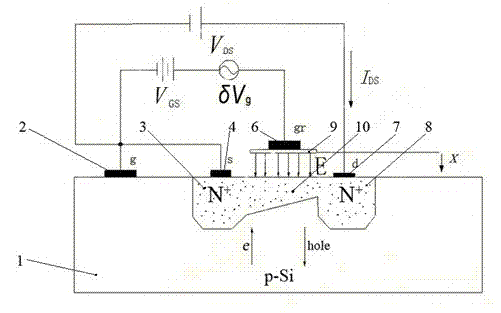

[0013] The structure of the nanoelectromechanical resonant sensor based on the graphene sheet in the present invention is as follows: figure 1 shown. A P-type silicon wafer with a low impurity concentration is used as a substrate, that is, a P-Si substrate 1, and two N + Regions, namely the drain-N type doped region 3 and the source-N type doped region 8, are on the surface of the P-Si substrate 1, and are located in the drain-N type doped region 3 and the source-N type In the middle of the doped region 8, two SiO 2 Anchor region 5, in two SiO 2 On the anchor area 5 is a graphene two-ends-fixed beam 9, and the two ends of the graphene-two-ends-fixed beam 9 are respectively suspended from two SiO 2 On the anchor region 5 , a top gate electrode 6 connected to the graphene double-end fixed beam 9 is arranged on one end of the graphene double-terminal fixed beam 9 . The drain electrode 4 and the source electrode 7 are located on the drain-N type doped region 3 and the source-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com