Metal interconnection structure and manufacturing method thereof

A metal interconnection structure and manufacturing method technology, applied in radiation control devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as color mixing and affecting imaging quality, reduce crosstalk, improve K value, The effect of easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

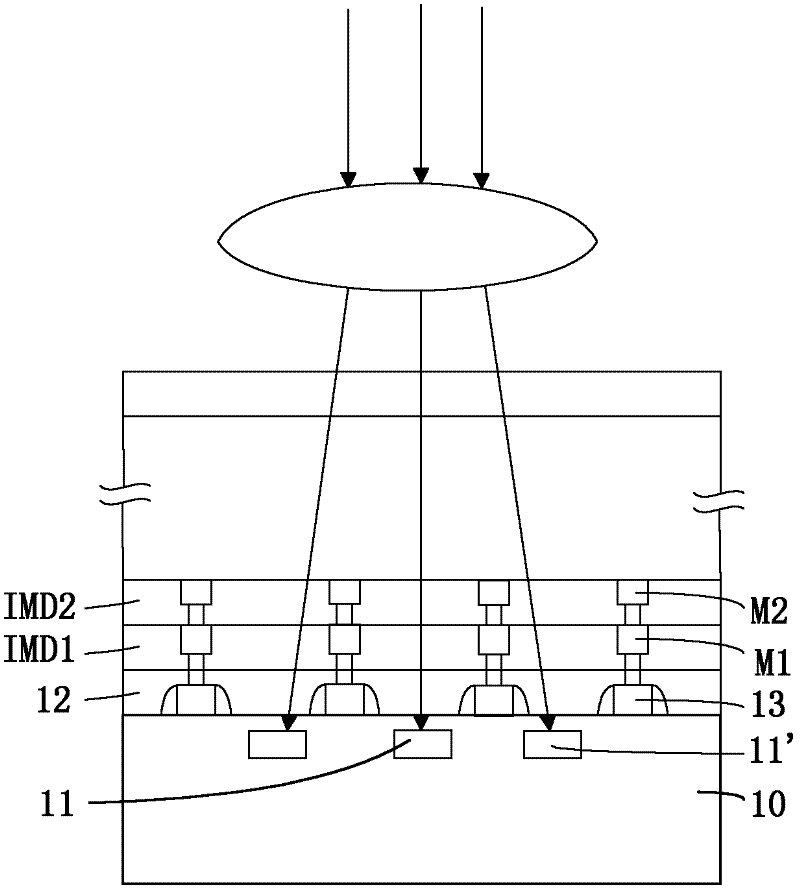

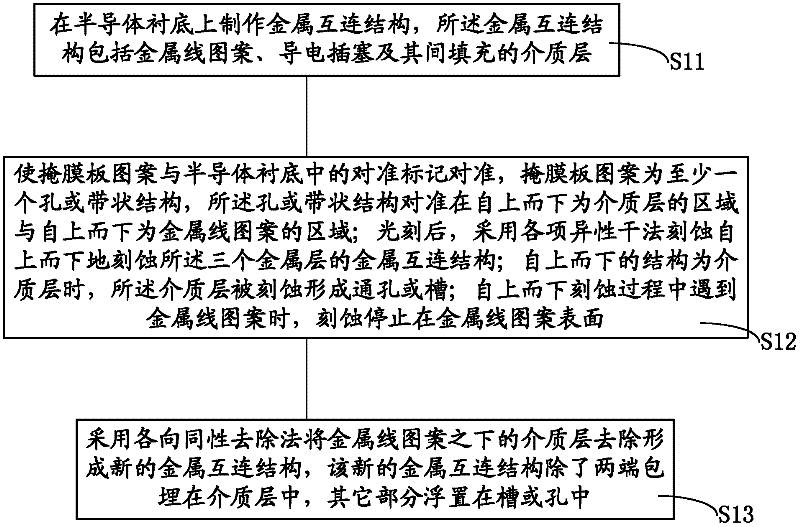

[0063] Taking the image sensor as an example, the metal interconnection structure and the manufacturing method therein will be introduced in detail below. figure 2 It is a flow chart of the method for fabricating the metal interconnection structure provided in the first embodiment. Figure 3 to Figure 6 It is a schematic diagram of the intermediate structure during the fabrication process of the metal interconnection structure. Figure 7 The completed top view for the metal interconnect structure, Figure 8 , Figure 9 respectively Figure 7 The cross-sectional view along the A-A line and the B-B line.

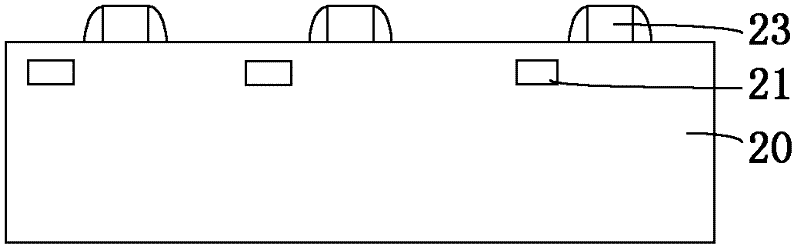

[0064] combine figure 2 , Figure 8 and Figure 9 , S11 is firstly performed to fabricate a metal interconnection structure 27 on the semiconductor substrate 20, the metal interconnection structure 27 including a metal line pattern, a conductive plug and a dielectric layer filled therebetween.

[0065] Specifically, in combination with the image sensor, the execution ...

Embodiment 2

[0098] During the execution of step S12, except that the hole or band structure in the mask pattern provided in the photolithography process of the first embodiment is aligned between the area of the dielectric layer from top to bottom and the metal line pattern from top to bottom Outside the region, the holes or band-shaped structures in the mask pattern provided in the photolithography process of the second embodiment are only aligned in the region of the dielectric layer from top to bottom, and the mask pattern is transferred to the photoresist After being put on, a strip-shaped exposure area 28' is formed, and its top view is as follows Figure 17 shown. Using the photoresist pattern as a mask, in the top-down etching process, only the dielectric layer is encountered, and the dielectric layer is etched to form through holes or grooves, and the cross-sectional view of the formed structure along the B-B line is as follows Figure 18 shown. The parameters used in the etch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com