Fully solid-state lithium secondary battery electrolyte material, preparation method thereof and fully solid-state lithium secondary battery

A technology for lithium secondary batteries and electrolyte materials, which is applied in the field of all-solid-state lithium secondary batteries, can solve the problems that lithium ion conductivity is difficult to achieve, and the conductivity needs to be further improved, so as to improve electrochemical stability and electrochemical stability. Good, improve the effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a method for preparing an electrolyte material for an all-solid lithium secondary battery, comprising the following steps:

[0043] Will Li 2 S, the first sulfide, the second sulfide and the dopant are mixed and then heat-treated or ground to obtain an electrolyte material for an all-solid lithium secondary battery, the first sulfide being GeS and / or GeS 2 , the second sulfide is FeS, FeS 2 、SiS 2 ,P 2 S 5 , B 2 S 3 、CeS 2 and Al 2 S 3 One or more of them, the dopant is a lithium salt or an oxide that can form ortho acid.

[0044] The present invention uses Li 2 S, the first sulfide, the second sulfide and the dopant are used as raw materials to prepare an all-solid-state lithium secondary battery electrolyte material, which has good properties such as electrical conductivity and electrochemical stability.

[0045] In the present invention, the Li 2 S and the second sulfide can form glass ceramics, that is, a composite material in whic...

Embodiment 1

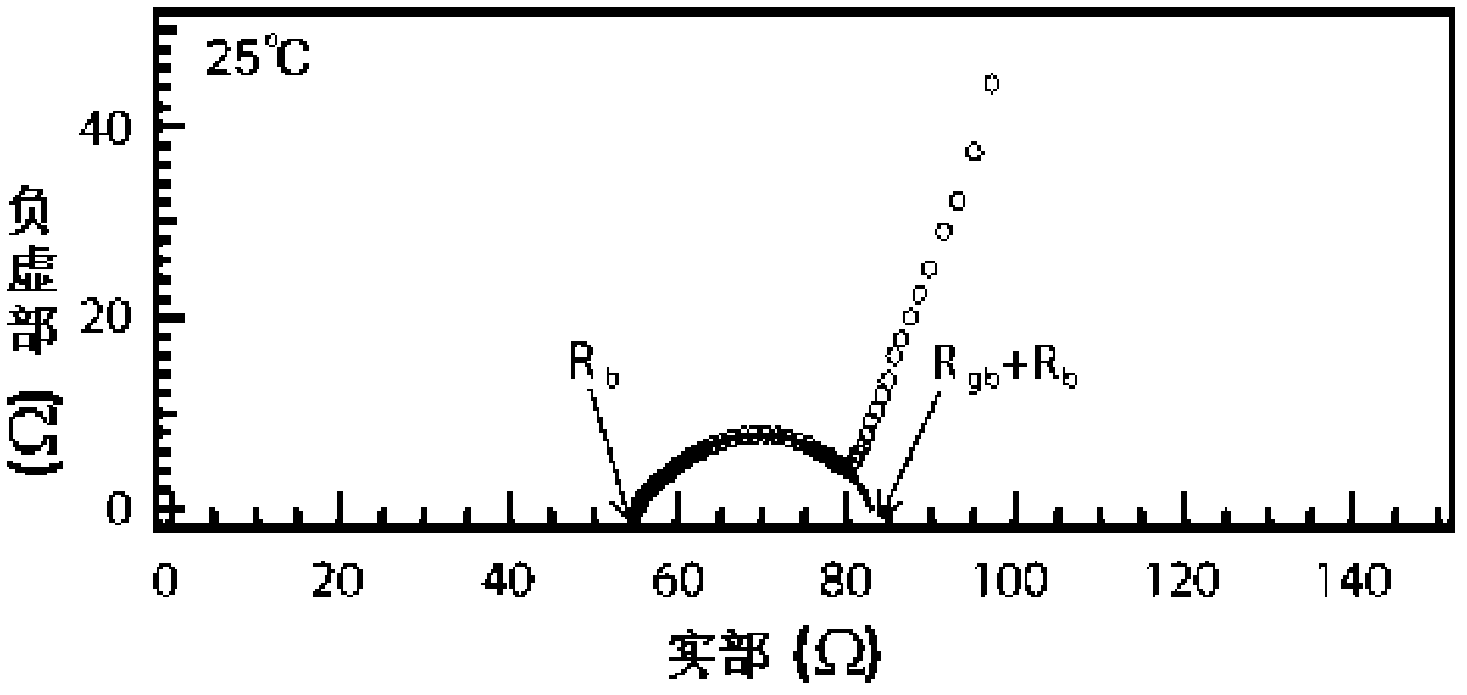

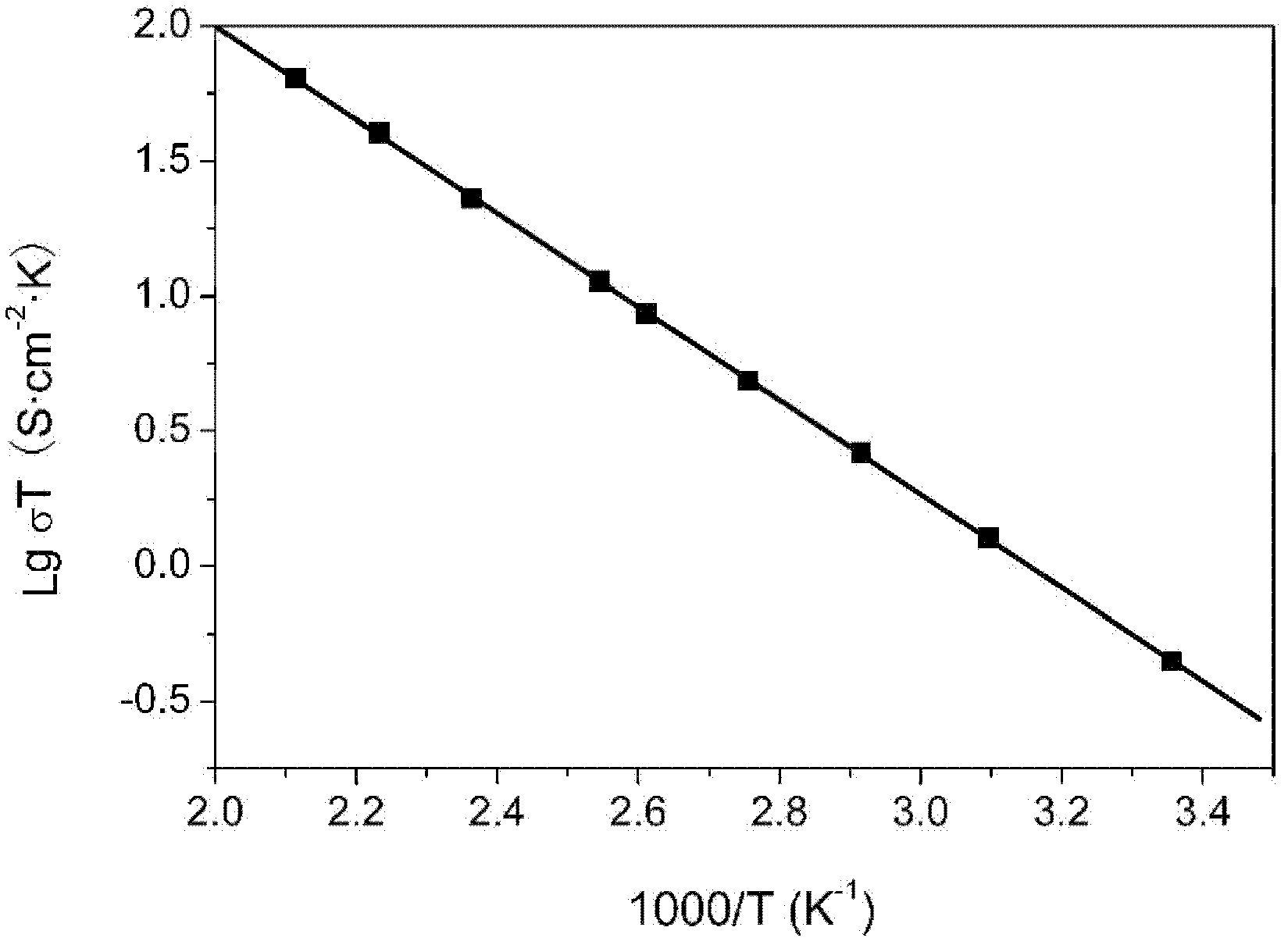

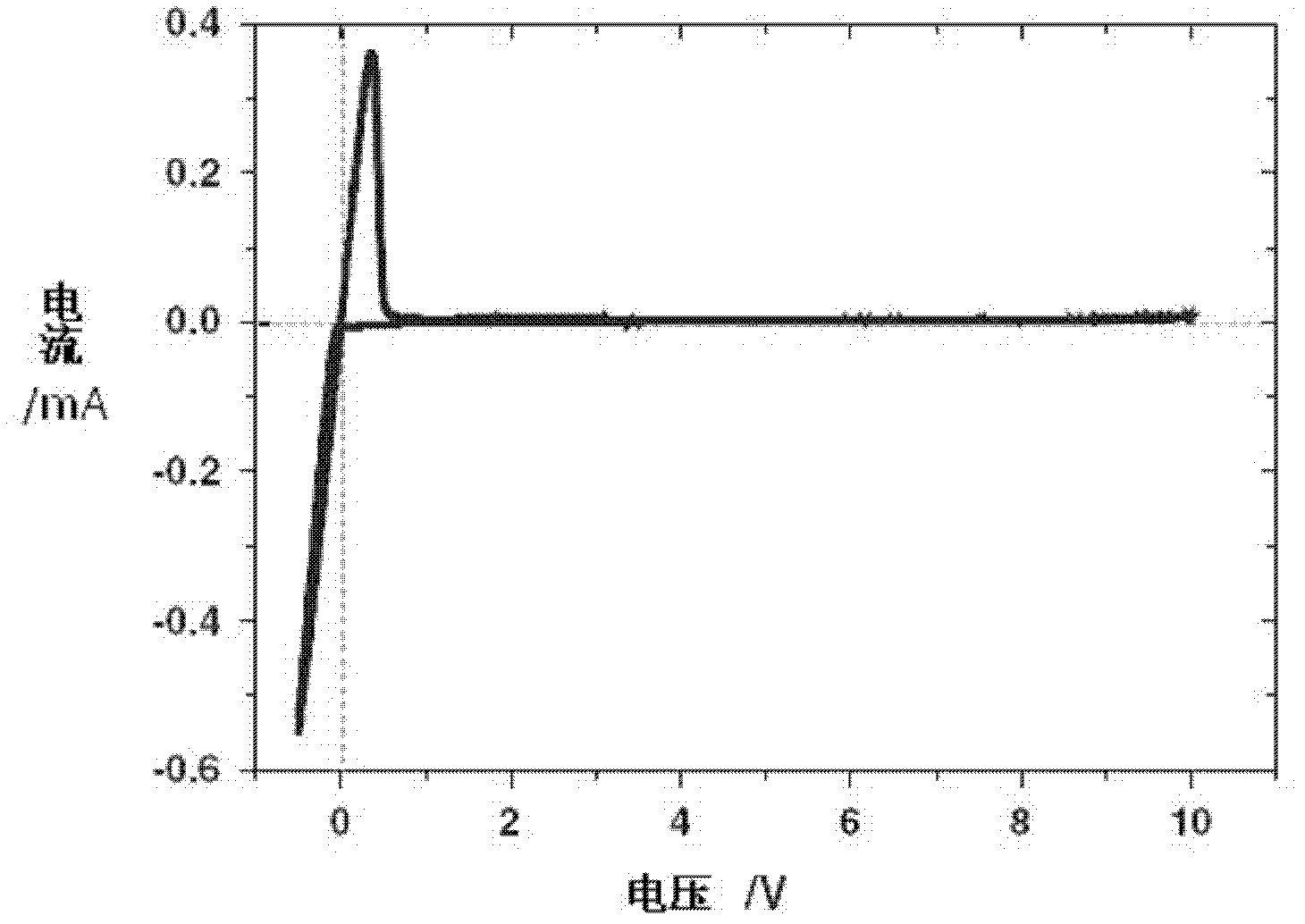

[0066] Under the protection of argon atmosphere, Li with a purity of more than 99% 2 S, GeS 2 ,P 2 S 5 with Li 3 PO 4 After weighing according to the molar ratio of 1:0.1:0.2:0.05, grind it under the condition that the water content is less than 100ppm, mix it evenly, put it into a quartz glass tube, vacuumize it to a vacuum degree of less than 100Pa, and melt it with a hydrogen-oxygen flame. Seal, heat the quartz glass tube containing the above mixture to 500 °C at a heating rate of 2 °C / min, keep it warm for 24 hours, cool it to room temperature with the furnace, open the tube under the condition of water content of 0.1 ppm and grind it evenly again, Then put it into the quartz glass tube again, evacuate until the vacuum degree is less than 100Pa, seal it with a hydrogen-oxygen flame, heat it to 500°C at a heating rate of 2°C / min, keep it for 24 hours, cool it to room temperature with the furnace, and grind it evenly. Obtain an all-solid-state lithium secondary battery ...

Embodiment 2

[0071] Under the protection of argon atmosphere, Li with a purity of more than 99% 2 S, GeS 2 ,P 2 S 5 with Li 3 TaO 4 After weighing according to the molar ratio of 1:0.08:0.23:0.1, grind it under the condition that the water content is less than 100ppm, mix it evenly, put it into a quartz glass tube, vacuumize it to a vacuum degree of less than 100Pa, and melt it with a hydrogen-oxygen flame. Seal, heat the quartz glass tube containing the above mixture to 650 °C at a heating rate of 2 °C / min, keep it warm for 12 hours, cool it to room temperature with the furnace, open the tube under the condition of water content of 0.1 ppm and grind it evenly again. Obtain an all-solid-state lithium secondary battery electrolyte material, that is, Li 3 TaO 4 Doped Li 2 S-GeS 2 -P 2 S 5 system.

[0072] According to the method of Example 1, the electrochemical performance of the all-solid-state lithium secondary battery electrolyte material obtained in this example was tested, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com