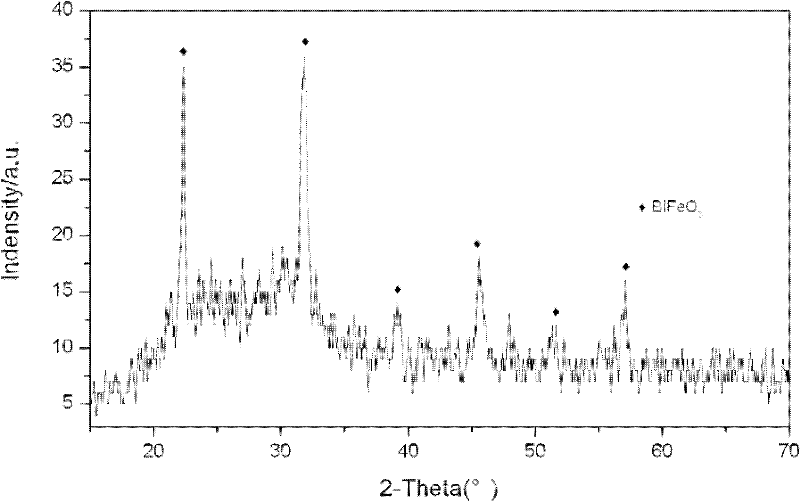

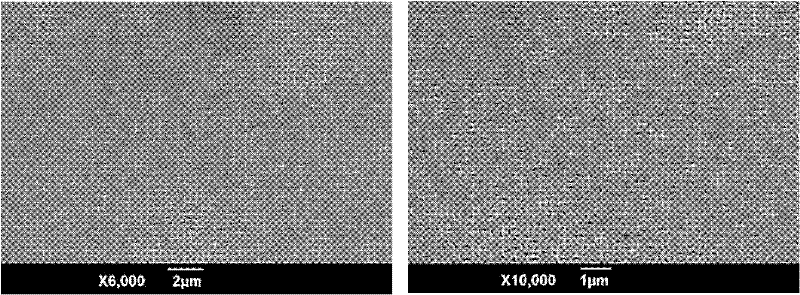

Method for preparing porous bismuth ferrate thin film by CSD (Chemical Solution Deposition) method

A bismuth ferrite, porous technology is applied in the field of preparing bismuth ferrite porous thin films by chemical solution deposition, which can solve the problems of reducing reaction activity, stoichiometric ratio imbalance, etc., and achieves simple process, large specific surface area, and enhanced photocatalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step 1: Select the ITO / glass substrate as the substrate, place the cut ITO / glass substrate in detergent, acetone, and ethanol in sequence for ultrasonic cleaning to remove grease and other impurities on the surface of the ITO / glass substrate Finally, rinse the substrate with a large amount of distilled water, and finally dry it with nitrogen;

[0019] Step 2: Place the ITO / glass substrate treated in step 1 in a UV irradiator for 20 minutes to make the surface of the substrate reach "atomic cleanliness". The high energy of UV irradiation can break the oxide bonds and form The hydroxyl group with better hydrophilicity can improve the hydrophilicity of the substrate;

[0020] Step 3: Fe(NO 3 ) 3 9H 2 O and Bi(NO 3 ) 3 ·5H 2 O was dissolved in ethylene glycol methyl ether and glacial acetic acid respectively, and mixed to form a precursor solution after dissolution. Adjust the concentration of Bi and Fe ions in the precursor solution to 0.01-1.0mol / L, and magnetically...

Embodiment 2

[0023] Step 1: Select the ITO / glass substrate as the substrate, place the cut ITO / glass substrate in detergent, acetone, and ethanol in sequence for ultrasonic cleaning to remove grease and other impurities on the surface of the ITO / glass substrate Finally, rinse the substrate with a large amount of distilled water, and finally dry it with nitrogen;

[0024] Step 2: Place the ITO / glass substrate treated in step 1 in a UV irradiator for 20 minutes to make the surface of the substrate reach "atomic cleanliness". The high energy of UV irradiation can break the oxide bonds and form The hydroxyl group with better hydrophilicity can improve the hydrophilicity of the substrate;

[0025] Step 3: Fe(NO 3 ) 3 9H 2 O and Bi(NO 3 ) 3 ·5H 2 O was dissolved in ethylene glycol methyl ether and glacial acetic acid respectively, and mixed to form a precursor solution after dissolution. Adjust the concentration of Bi and Fe ions in the precursor solution to 0.01mol / L, and magnetically sti...

Embodiment 3

[0028] Step 1: Select the ITO / glass substrate as the substrate, place the cut ITO / glass substrate in detergent, acetone, and ethanol in sequence for ultrasonic cleaning to remove grease and other impurities on the surface of the ITO / glass substrate Finally, rinse the substrate with a large amount of distilled water, and finally dry it with nitrogen;

[0029] Step 2: Place the ITO / glass substrate treated in step 1 in a UV irradiator for 20 minutes to make the surface of the substrate reach "atomic cleanliness". The high energy of UV irradiation can break the oxide bonds and form The hydroxyl group with better hydrophilicity can improve the hydrophilicity of the substrate;

[0030] Step 3: Fe(NO 3 ) 3 9H 2 O and Bi(NO 3 ) 3 ·5H 2 O was dissolved in ethylene glycol methyl ether and glacial acetic acid respectively, and mixed to form a precursor solution after dissolution. The concentration of Bi and Fe ions in the precursor solution was adjusted to 0.1mol / L, and magnetic st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com