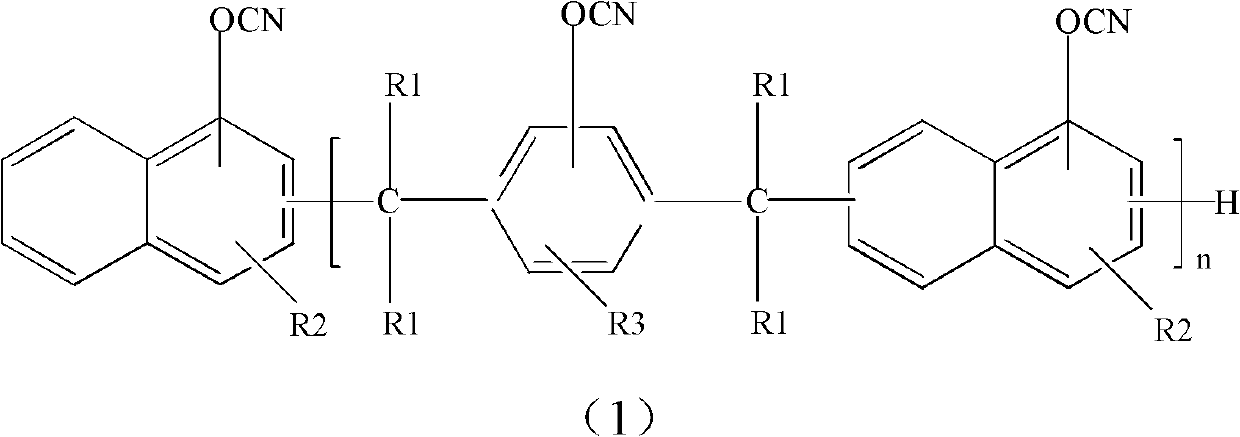

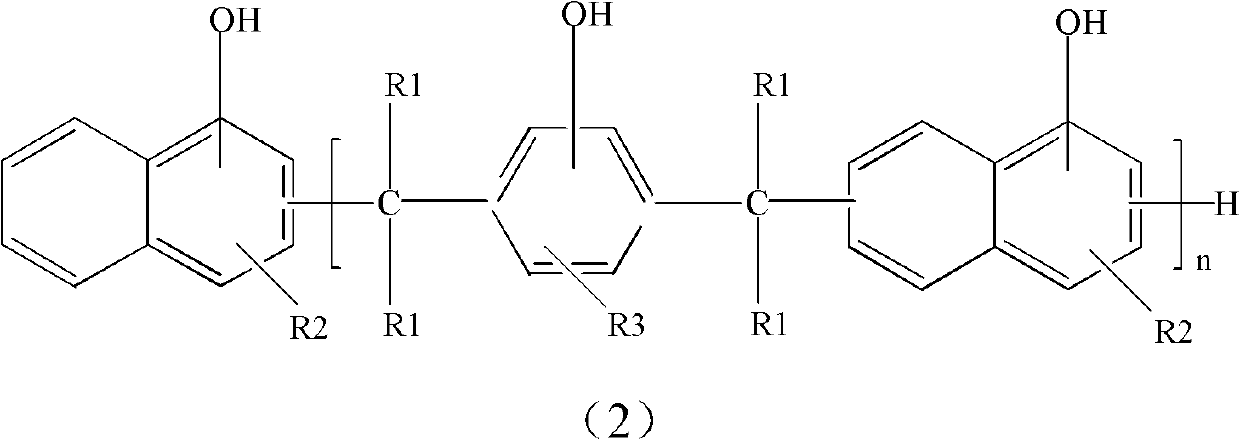

Naphthol phenolic cyanate ester resin and synthesis method thereof

A technology for naphthol novolac cyanate and naphthol novolac resin, which is applied in the field of polymer synthesis, can solve the problems of low yield, high product impurity content, can not meet the performance requirements of matrix resin, etc., and achieves good heat resistance. properties, reducing side reactions, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The synthetic method of naphthol novolac type cyanate resin of the present invention, comprises the steps:

[0041] Step 1: Dissolving the naphthol phenolic resin and the catalyst in an organic solvent, and fully stirring to dissolve and mix evenly; the catalyst is trialkylamine, preferably triethylamine.

[0042] Step 2: Add the solvent and cyanogen halide into the reaction kettle, and stir fully to make it evenly mixed; the solvent is a single solvent or a mixed solvent in ethers, ketones, esters, chlorinated hydrocarbons, aromatics, tetrahydrofuran, preferably Dichloromethane or trichloromethane; cyanogen halide is cyanogen chloride or cyanogen bromide, preferably cyanogen chloride. Wherein the feeding ratio of each component in steps 1 and 2 is as follows: naphthol phenolic resin (equivalent) 1.0; cyanogen halide (equivalent) 1.1-2.0; catalyst (equivalent) 1.0-1.5.

[0043] Step 3: Keep the temperature in step 2 stable at 0°C to -20°C, add the uniformly mixed solut...

Embodiment 1

[0048] Add 300 g of chloroform and 0.98 mol of cyanogen chloride into the three-necked flask, stir well to make them evenly mixed, and stabilize the temperature at -10°C. 70g (OH group content 0.50mol) naphthol phenolic resin (softening point: 92 ° C, OH equivalent: 140g / eq, provided by Nippon Kayaku Co., Ltd., structural formula as shown in (3) formula), 0.74mol triethylamine Dissolve in 700g of chloroform and mix evenly, slowly add this solution dropwise to the above cyanogen chloride solution in chloroform at -10°C, the dropping time is more than 120min. After the dropwise addition was completed, the reaction was continued for 3 hours to end the reaction. The salt generated by the reaction was filtered off with a funnel, and the resulting filtrate was washed with 500 milliliters of 0.1 mol / L hydrochloric acid, and then washed five times with deionized water until neutral. Sodium sulfate was added to the separated chloroform solution to remove the moisture in the chloroform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com