Itaconate/isoprene copolymer type bio-based engineering elastomer and preparation method thereof

A technology of itaconate and isoprene, which is applied in the field of itaconate/isoprene copolymer bioengineering rubber and its preparation, can solve the problem of low glass transition temperature, high viscosity, inability to vulcanize cross-linking Link and other issues to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

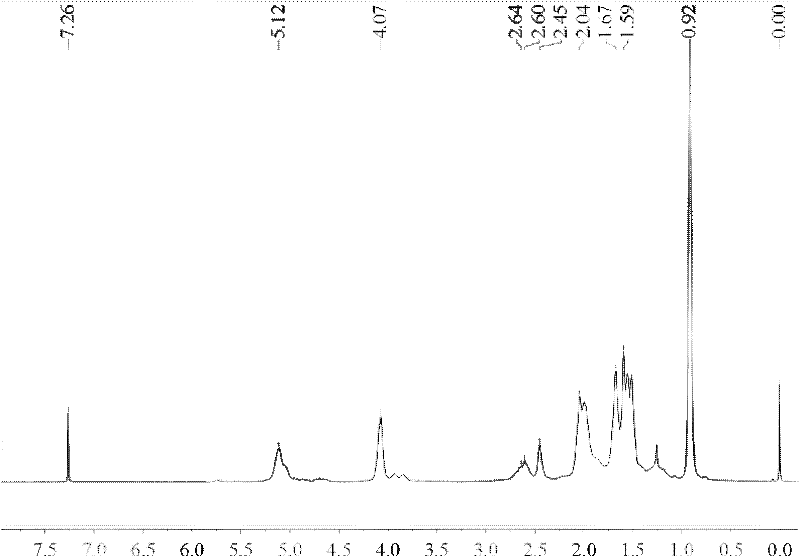

[0032] Add 52.04 grams (0.4mol) of itaconic acid, 73.71 grams (1.6mol) of ethanol, 15.6 grams (0.185mol) of cyclohexane , 0.368 gram (0.00376mol) the concentrated sulfuric acid of mass concentration 98% and 0.0104 gram hydroquinone, be warming up to 120 ℃ under stirring condition, esterification reaction 3 hours, obtain the mixture that contains itaconate. The mixture was then washed with deionized water in a separatory funnel and distilled under reduced pressure at 300 Pa. Collect 140~145°C distillate, which is diethyl itaconate monomer.

[0033] In a 1-liter reactor, add 90 grams of the above-mentioned diethyl itaconate monomer, 10 grams of isoprene, 5 grams of sodium lauryl sulfate, 5 grams of OP-10 emulsifier, 2 grams of sodium bicarbonate, Pressurize to 0.5MPa, pre-emulsify for 1 hour. Then, 0.7 g of ammonium persulfate was added into the reactor, the temperature was raised to 70° C., and the reaction was carried out for 24 hours to obtain a diethyl itaconate / isoprene c...

Embodiment 2

[0036] Add 52.04 grams (0.4mol) of itaconic acid, 73.71 grams (1.6mol) of ethanol, 15.6 grams (0.185mol) of cyclohexane , 0.368 grams (0.00376mol) of concentrated sulfuric acid with a mass concentration of 98% and 0.0104 grams of hydroquinone were heated up to 120° C. under stirring conditions, and esterified for 3 hours to obtain a mixture containing itaconate monomers. The mixture was then washed with deionized water in a separatory funnel and distilled under reduced pressure at 300 Pa. Collect 140~145°C distillate, which is diethyl itaconate monomer.

[0037] In a 1-liter reactor, add 80 grams of the above-mentioned diethyl itaconate monomer, 20 grams of isoprene, 5 grams of sodium dodecylsulfonate, 5 grams of OP-10 emulsifier, and 2 grams of sodium bicarbonate , pressurized to 0.5MPa, and pre-emulsified for 1 hour. Then, 0.7 g of potassium persulfate was added to the reactor, the temperature was raised to 70° C., and the reaction was carried out for 24 hours to obtain a ...

Embodiment 3

[0040] Add 52.04 grams (0.4mol) of itaconic acid, 96.16 grams (1.6mol) of propanol, 15.6 grams (0.185mol) of cyclohexane Alkanes, 0.368 grams (0.00376mol) of concentrated sulfuric acid with a mass concentration of 98% and 0.0104 grams of hydroquinone were heated up to 120° C. under stirring conditions, and esterified for 3 hours to obtain a mixture containing itaconate monomers. The mixture was then washed with deionized water in a separatory funnel and distilled under reduced pressure at 300 Pa. Collect 157~160℃ distillate, which is dipropyl itaconate monomer.

[0041] In a 1-liter reactor, add 90 grams of the above-mentioned dipropyl itaconate monomer, 10 grams of isoprene, 5 grams of sodium lauryl sulfate, 5 grams of OP-10 emulsifier, 2 grams of sodium bicarbonate, Pressurize to 0.5MPa, pre-emulsify for 1 hour. Then, 0.7 g of ammonium persulfate was added into the reactor, the temperature was raised to 70° C., and the reaction was carried out for 24 hours to obtain a dipr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com