Spoke noise reduction damping polymer material and preparation method thereof

A polymer material and noise reduction technology, applied in the field of polymer damping material manufacturing, can solve the problem of polyurethane not showing heat storage performance, etc., and achieve the effects of high saturated vapor pressure, good damping performance, and non-volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

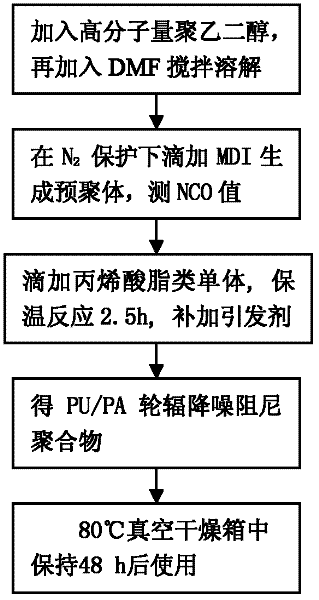

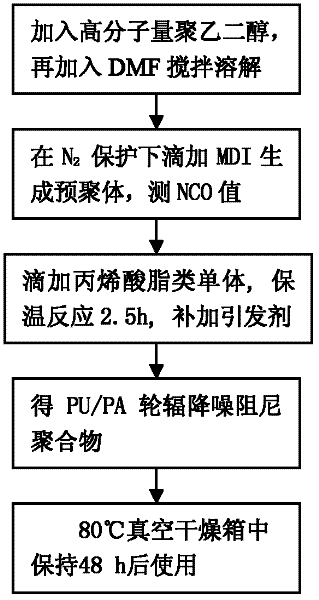

Method used

Image

Examples

Embodiment 1

[0019] PU / PA (polyurethane / polyacrylate) samples were prepared by two-step solution polymerization. Add PEG (high molecular weight polyethylene glycol, 25g) that has been vacuum dehydrated at 100°C for 3.5h into an appropriate amount of DMF (dimethylformamide, 60ml), stir and dissolve, then add metered MDI (diphenylmethane diisocyanate , 23 g), at N 2 Under protection, react at 60°C for 2.5h to generate NCOPEG prepolymer. At 2.5 hours, take a sample of 1-2g and measure the NCO value in the conical flask with the di-n-butylamine method. Add and measure BDO (butanediol, 8 grams) according to the measured NCO value, and after the chain extension reaction for 2 hours, stir at high speed Add acrylate monomer (containing 0.9% dissolved initiator AIBN, 42 grams in total), the reaction temperature is controlled at 70° C., and the monomer addition is completed within 1.5 hours. Additional initiator AIBN (0.05% of the total amount of acrylic ester monomers) was added, and after the ad...

Embodiment 2

[0021] PU / PA (polyurethane / polyacrylate) samples were prepared by two-step solution polymerization. Add PEG (high molecular weight polyethylene glycol, 32.5g) that has been dehydrated under vacuum for 4 hours at 110°C to an appropriate amount of DMF (dimethylformamide, 80ml), stir and dissolve, then add metered MDI (diphenylmethane diisocyanate , 29.5 g), at N 2 Under protection, react at 65°C for 2.5h to generate NCOPEG prepolymer. At 2.5 hours, take a sample of 1-2 g and measure the NCO value in a conical flask with the di-n-butylamine method. Add and measure BDO (butanediol, 11.5 grams) according to the NCO value measured, after chain extension reaction 2.5h, acrylic ester monomer (containing 0.9% initiator AIBN of dissolving, total 51 grams) is stirred dropwise at high speed , the reaction temperature was controlled at 75°C, and the monomer addition was completed within 2 hours. Additional initiator AIBN (0.05% of the total amount of acrylic monomers) was added, and aft...

Embodiment 3

[0023] PU / PA (polyurethane / polyacrylate) samples were prepared by two-step solution polymerization. Add PEG (high molecular weight polyethylene glycol, 40g) that has been dehydrated under vacuum for 5 hours at 120°C to an appropriate amount of DMF (dimethylformamide, 100ml), stir and dissolve, then add metered MDI (diphenylmethane diisocyanate, 36 g), at N 2 Under protection, react at 70°C for 2.5h to generate NCOPEG prepolymer. At 2.5h, take a sample of 1-2g and measure the NCO value in the conical flask with the di-n-butylamine method. Add and measure BDO (butanediol, 15 grams) according to the measured NCO value, and after the chain extension reaction for 3 hours, stir at high speed and drop Add acrylate monomer (containing 0.9% dissolved initiator AIBN, 60 grams in total), the reaction temperature is controlled at 80° C., and the monomer addition is completed within 2.5 hours. Additional initiator AIBN (0.05% of the total amount of acrylic ester monomers) was added, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com