Chromium-free waterborne epoxy anticorrosion primer with excellent solvent oil resistant performance

A water-based epoxy and anti-corrosion primer technology, used in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as hardness drop, softening of paint film, foaming, etc., and achieve the effect of good anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

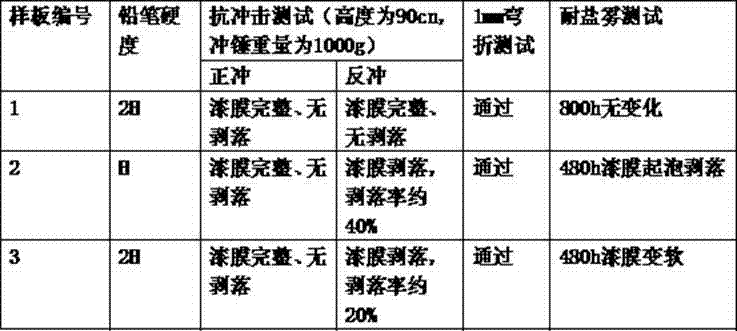

Examples

Embodiment 1

[0052] Component A: self-made water-based epoxy resin emulsion: 4.5kg, 500g zinc phosphate, 660g zinc calcium phosphomolybdate, 1.2kg talc powder, 900g mica powder, 1kg light calcium carbonate, 340g silane coupling agent, 48g preservative , Anti-flash rust agent 20g, film-forming aid 30g, defoamer 40g, wetting and dispersing agent 40g.

[0053] Component B: self-made water-based epoxy curing agent: 4kg, co-solvent: 500g, deionized water 5.5kg.

[0054] A and B components are used in combination at a weight ratio of 3.1:1.

Embodiment 2

[0056] Component A: self-made water-based epoxy resin emulsion: 4 kg, zinc phosphate 600g, aluminum tripolyphosphate 800g, talc powder 1.1kg, mica powder 1kg, light calcium carbonate 800g, silane coupling agent 330g, preservative 50g, Anti-flash rust agent 23g, film-forming aid 30g, defoamer 42g, wetting and dispersing agent 40g.

[0057] Component B: self-made water-based epoxy curing agent: 4.4kg, co-solvent: 600g, deionized water 5kg.

[0058] A and B components are used in combination at a weight ratio of 2.7:1.

Embodiment 3

[0060] Component A: self-made water-based epoxy resin emulsion: 4.5 kg, 600 g of zinc phosphate, 300 g of potassium zinc phosphate, 500 g of aluminum tripolyphosphate, 1.1 kg of talc powder, 1.1 kg of mica powder, 800 g of light calcium carbonate, silane coupling agent 300g, preservative 50g, anti-flash rust agent 25g, film-forming aid 25g, defoamer 40g, wetting and dispersing agent 40g.

[0061] Component B: self-made water-based epoxy resin curing agent: 4.5kg, co-solvent: 500g, deionized water 5kg.

[0062] A and B components are used in combination at a weight ratio of 2.9:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com