Aqueous polyurethane heat reflection coating and application thereof

A water-based polyurethane and heat-reflective technology, which is applied in polyurea/polyurethane coatings, reflective/signal coatings, coatings, etc., can solve problems such as application limitations, and achieve improved cross-linking density, improved water resistance, and good heat reflection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

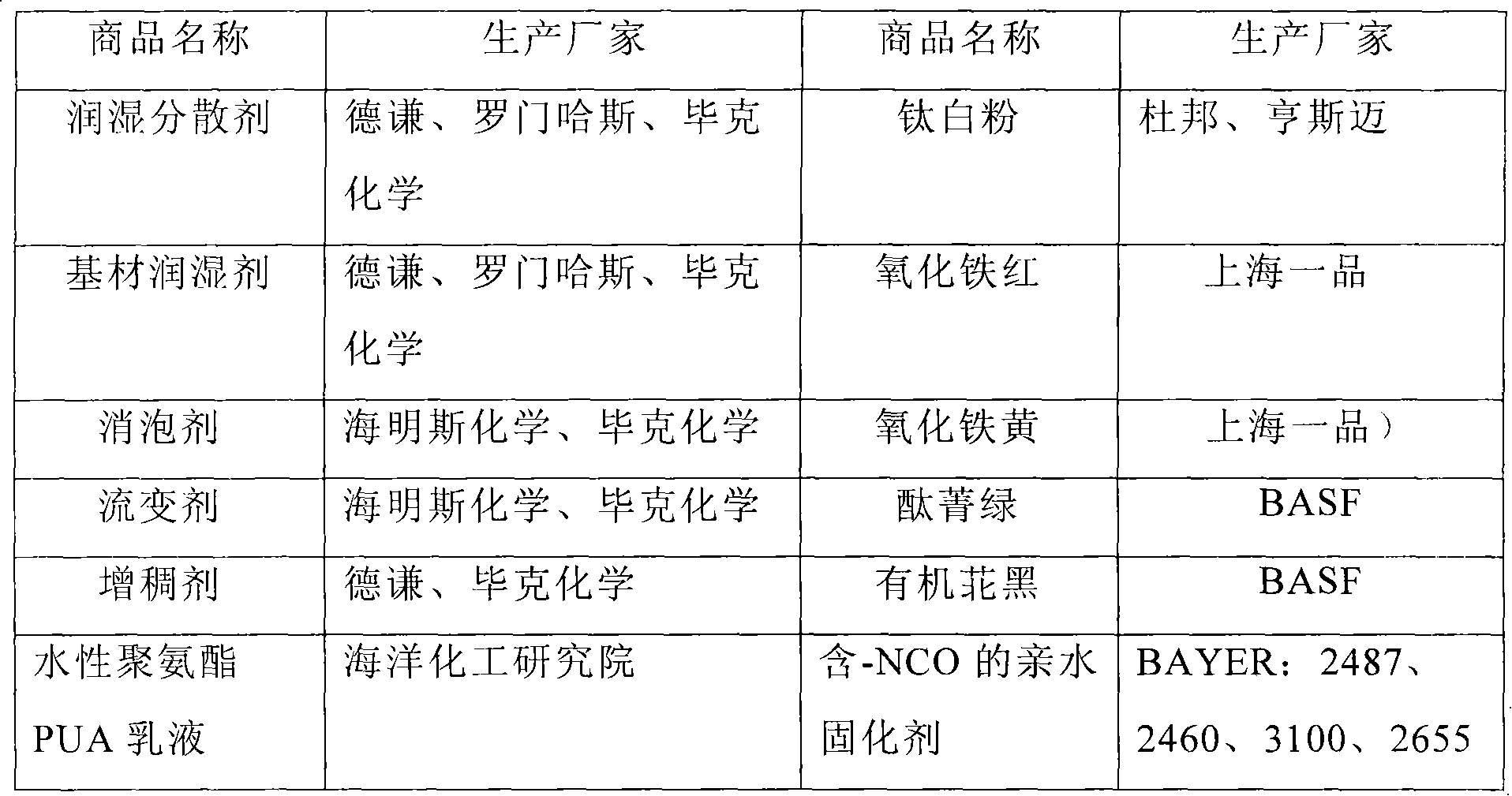

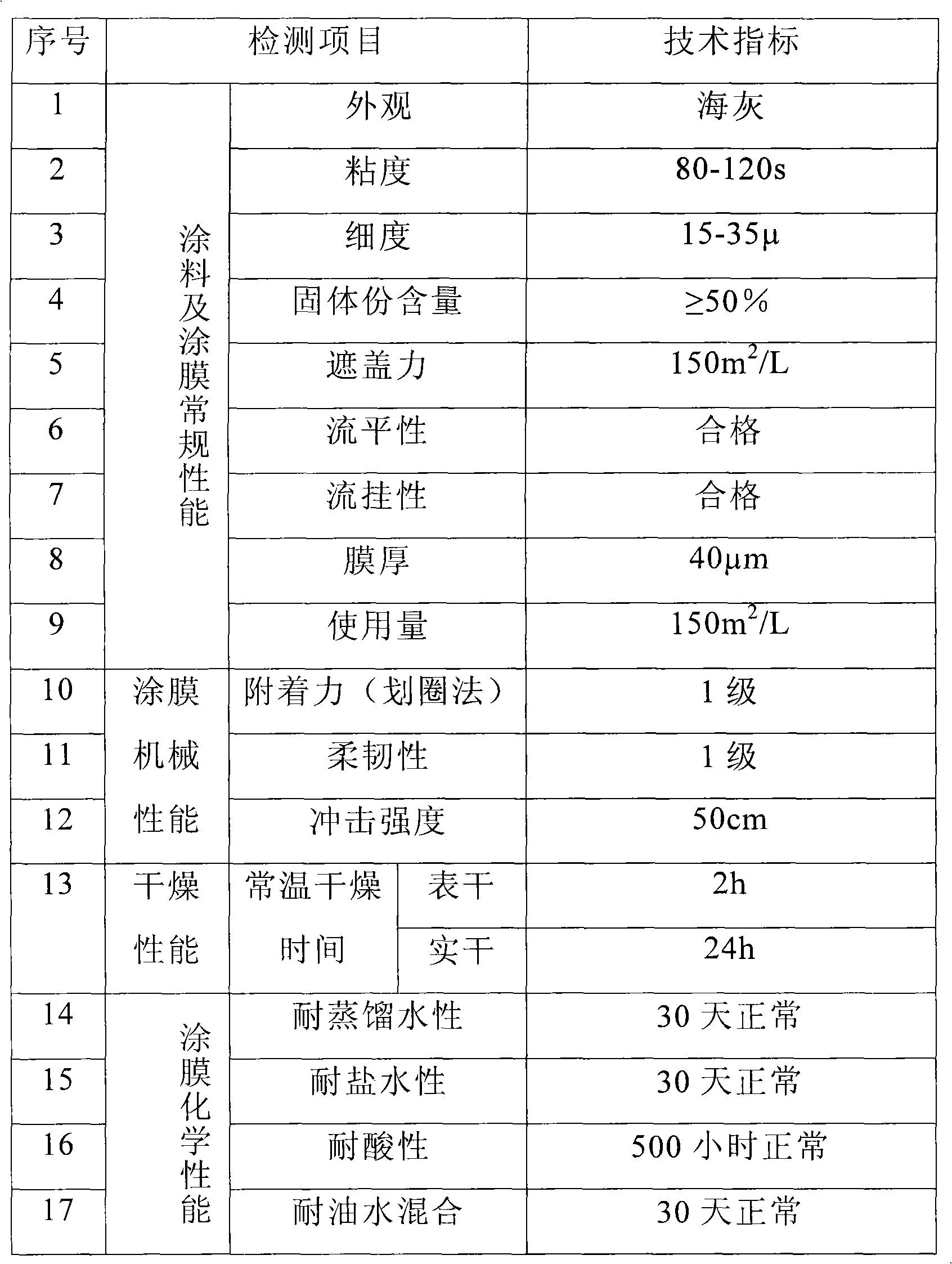

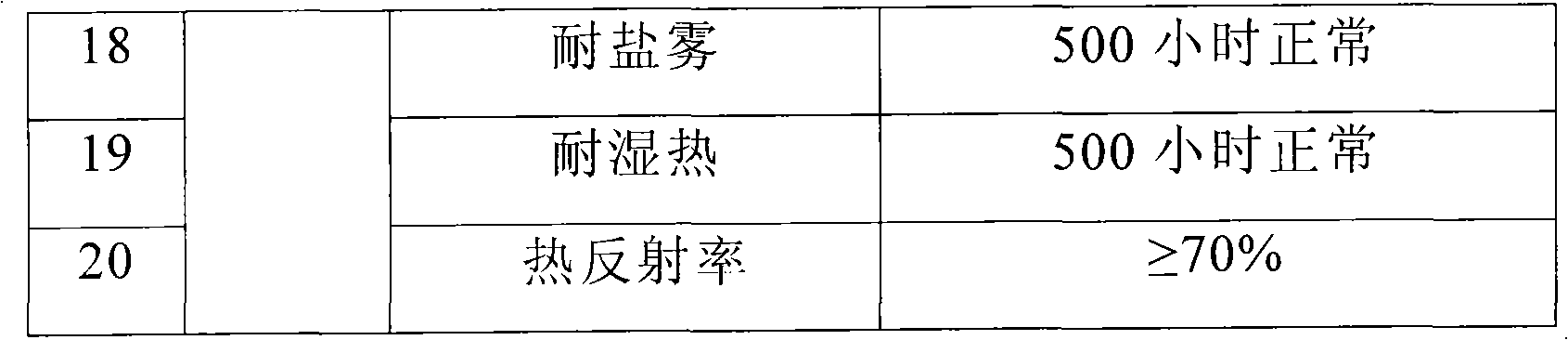

Method used

Image

Examples

Embodiment 1

[0052] The proportion of component A in parts by weight is:

[0053] 10 parts of water, 100 parts of water-based polyurethane PUA emulsion, 17.2 parts of titanium dioxide, 4.5 parts of organic perylene black, 10 parts of mica powder, 5 parts of fumed silica, 5 parts of hollow ceramic beads, 0.32 parts of Disponer W-18, DeuAdd MB -11 1.5 parts, NAZIA FA 379 1.5 parts, RHEOLATE 125 3.2 parts, Levaslip W-461 1.5 parts.

[0054] The second component is: 11 parts of the hydrophilic curing agent BAYER 2655 containing -NCO.

[0055] The paint mixing process is as follows: Mix components A and B and water in proportion, stir evenly at 300-500 rpm, adjust the viscosity for 40 seconds (coating -4), and make the board by spraying or brushing. Thickness: 40um primer and 40um topcoat.

Embodiment 2

[0057] The proportion of component A in parts by weight is:

[0058] 0 parts of water, 100 parts of water-based polyurethane PUD emulsion, 17.8 parts of titanium dioxide, 3.4 parts of iron oxide red, 18 parts of iron oxide yellow, 20 parts of phthalocyanine blue, 10 parts of barium sulfate, 10 parts of hollow glass beads, Disponer W-19 0.32 parts, Dispenor W-519 1.7 parts, Deform W-052 0.32 parts, DeuAdd MB-16 1.5 parts, NAZIA FA 579 1.5 parts, BENTONE DY 1.5 parts.

[0059] Part B: Coupling agent KH-560, the addition amount is 2% of the total weight of Part A.

[0060] The paint mixing process is the same as in Example 1.

Embodiment 3

[0062] The proportion of component A in parts by weight is:

[0063] 0 parts of water, 100 parts of water-based polyurethane emulsion, 17.1 parts of titanium dioxide, 6.4 parts of permanent red, 0.8 parts of iron oxide yellow, 1.6 parts of phthalocyanine green, 1 part of phthalocyanine blue, 0.32 parts of Disponer W-19, Disponer W-519 9 Parts, 5 parts of fumed silica, 5 parts of power plant float beads, 10 parts of barium sulfate, 0.3 parts of Deform W-092, 3.2 parts of RHEOLATE125, 1.5 parts of DeuAdd MB-11, 5 parts of Tamol165.

[0064] Part B: 11 parts of the hydrophilic curing agent BAYER 3100 containing -NCO.

[0065] The paint mixing process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com