Dry film lubricant composition

A technology of dry film lubricants and compositions, applied in the directions of lubricating compositions, petroleum industry, etc., can solve the problems of reducing the curing efficiency of dry film lubricants, unfavorable for large-scale use, and high curing temperature requirements, and achieves less sagging defects. , low price, good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Mix 5800mL of acetone, 600mL of xylene, 1000mL of ethylene glycol ethyl ether and 2500mL of H 30-15 epoxy ester drying insulating varnish produced by Shanghai Kailin Paint Factory and put them in an iron can. 600g of the colloidal graphite powder of the model F-1 produced by Shanghai Graphite Powder Factory, after stirring evenly, the obtained mixture is filtered twice through a steel wire sieve with a pore size of 0.045mm to obtain a dry film lubricant composition.

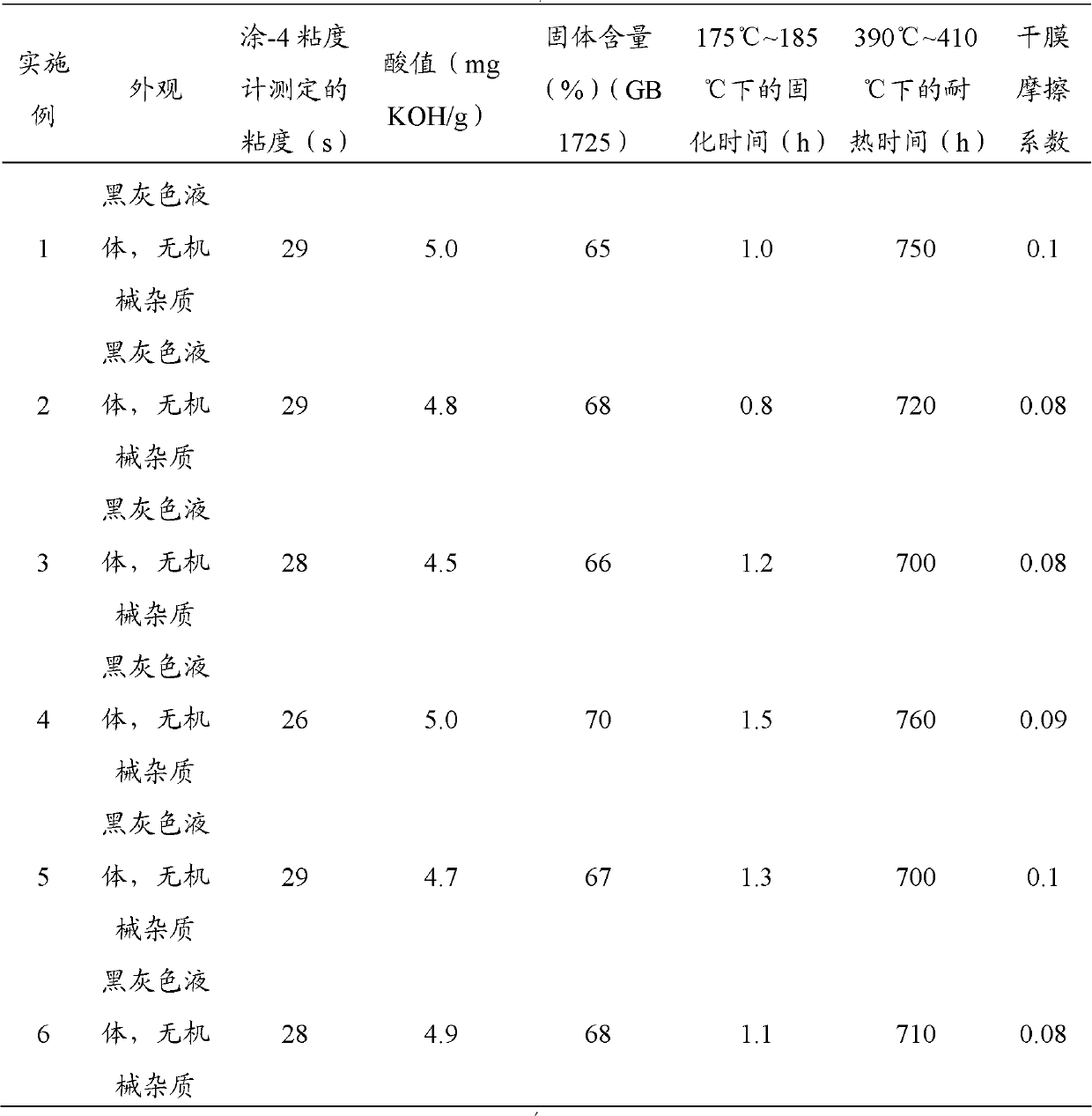

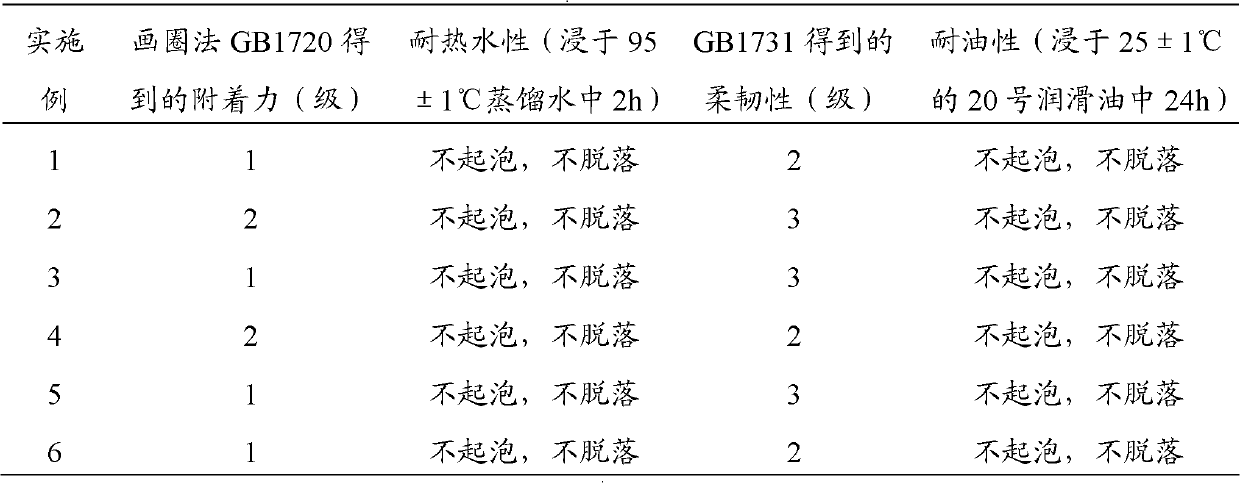

[0053] The present invention tests the technical indicators of the obtained dry film lubricant composition, and the results are shown in Table 1. Table 1 shows the technical indicators of the dry film lubricant compositions obtained in Examples 1-6 of the present invention.

[0054] The present invention tests the adhesion performance, hot water resistance, flexibility and oil resistance of the obtained dry film lubricant composition, and the results are shown in Table 2. Table 2 shows the dry film lubrican...

Embodiment 2

[0056] Mix 6960mL of acetone, 720mL of xylene, 600mL of ethylene glycol ethyl ether, 600mL of absolute ethanol and 2760mL of H 30-15 epoxy ester drying insulating varnish produced by Shanghai Kailin Paint Factory and put them in an aluminum can, stir After uniformity, 600g of colloidal graphite powder of model F-1 produced by Shanghai Graphite Powder Factory was added thereto, and after uniform stirring, the obtained mixture was filtered 3 times through a steel wire sieve with a pore size of 0.045mm to obtain a dry film lubricant composition.

[0057] The present invention tests the technical indicators of the obtained dry film lubricant composition, and the results are shown in Table 1. Table 1 shows the technical indicators of the dry film lubricant compositions obtained in Examples 1-6 of the present invention.

[0058] The present invention tests the adhesion performance, hot water resistance, flexibility and oil resistance of the obtained dry film lubricant composition, an...

Embodiment 3

[0060] Mix 8700mL of acetone, 900mL of xylene, 1000mL of ethylene glycol ether, 500mL of absolute ethanol and 3750mL of H 30-15 epoxy ester drying insulating varnish produced by Shanghai Kailin Paint Factory and put them in an iron tank, stir After uniformity, 900g of colloidal graphite powder of model F-1 produced by Shanghai Graphite Powder Factory was added thereto, and after uniformity, the obtained mixture was filtered 3 times through a steel wire sieve with a pore size of 0.045mm to obtain a dry film lubricant composition.

[0061] The present invention tests the technical indicators of the obtained dry film lubricant composition, and the results are shown in Table 1. Table 1 shows the technical indicators of the dry film lubricant compositions obtained in Examples 1-6 of the present invention.

[0062] The present invention tests the adhesion performance, hot water resistance, flexibility and oil resistance of the obtained dry film lubricant composition, and the results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com