Preparation method of grafted quaternary phosphonate ionic liquid

An ionic liquid and quaternary phosphine technology, which is applied in the field of preparation of grafted quaternary phosphine type ionic liquids, can solve the problems of weak physical force and loss of ionic liquid, and achieves good adsorption performance, good CO2 adsorption performance, and large cumulative specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

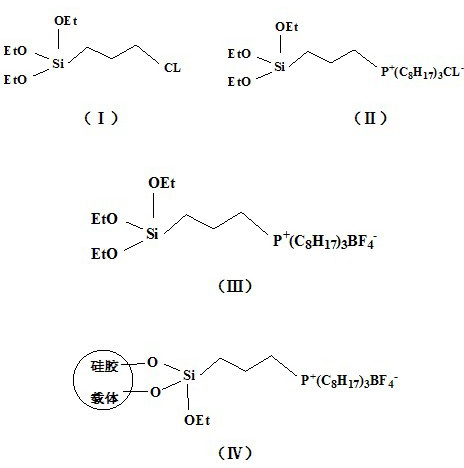

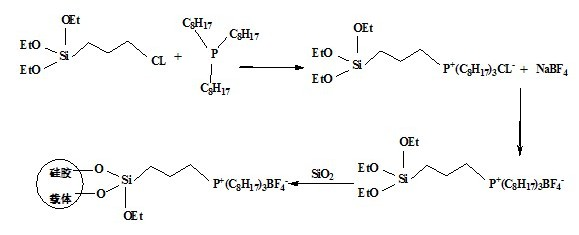

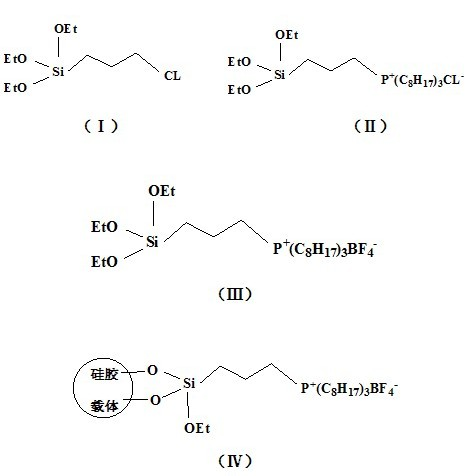

[0018] The synthesis of embodiment 1 chloride quaternary phosphine ionic liquid intermediate (II)

[0019] Add 20ml of anhydrous toluene into the three-necked flask, N 2 Protection; add 3.0g 3-chloropropyltriethoxysilane (I) into toluene with a syringe, then add 6.0g trioctylphosphine in the same way; heat and reflux in an oil bath at 120°C for 24h; react The product was allowed to stand, and the layers were separated. The ionic liquid phase was taken and washed three times with ether to remove toluene and unreacted substances; vacuum-dried at 80°C for 24 hours to obtain the brown-yellow quaternary phosphine chloride ionic liquid intermediate (Ⅱ).

Embodiment 2 4

[0020] Example 2 Synthesis of Tetrafluoroboric Acid Ionic Liquid Intermediate (Ⅲ)

[0021] Put 1.9 g of the quaternary phosphine chloride ionic liquid intermediate (II) obtained in the previous step into a three-necked flask, then add 0.6 g (excess) sodium tetrafluoroborate into the flask under constant stirring, and then add 150 mL acetonitrile, stirred and reacted for 35 h; the two salts gradually dissolved and a new white precipitate was formed. Since the precipitates before and after the reaction were all white, the reaction process was not obvious; the precipitate was removed by filtration, and about 750 mL of ether was added to the filtrate. White crystals were formed; the white precipitate was obtained by filtration, and vacuum-dried at room temperature for 10 h to obtain tetrafluoroborate ionic liquid intermediate (Ⅲ).

Embodiment 3

[0022] Example 3 Synthesis of grafted quaternary phosphine-type ionic liquid (IV)

[0023] Calcinate the silica carrier at 550°C for 6 hours, add 150ml of toluene to the flask, add 1.6 g of tetrafluoroborate ionic liquid (Ⅲ) into the toluene, and use N 2 Exhaust the air; add 2.0 g carrier, and stir the reaction mixture at 90°C for 3h; vacuum dry at 110°C for 2h to obtain the final product grafted quaternary phosphine-type ionic liquid (Ⅳ) particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com