MEMS (micro-electromechanical system) and IC (integrated circuit) monolithical integration method

A monolithic integration, substrate technology, applied in coatings, microstructure devices, microstructure technology, etc., can solve the problems of low stress, difficult to make silicon nitride films, etc., achieve high yield and simplify integration Manufacturing process, the effect of reducing parasitic capacitance and distributed capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The method of the present invention is specifically described below by taking the preparation of a monolithic integrated flat capacitive resonator as an example, and the manufacturing steps are as follows:

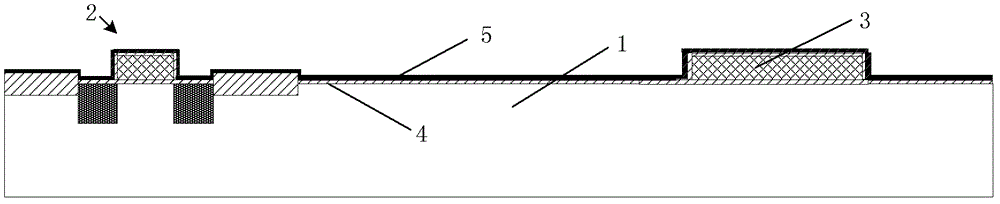

[0040] 1. The monocrystalline silicon substrate is used as the substrate 1 of the chip, and the CMOS circuit 2 is manufactured on the substrate 1 by IC technology, and all processes except metal interconnection are completed; MEMS devices can be manufactured at the same time when the polysilicon gate of the MOS device is manufactured polysilicon bottom electrode 3

[0041] 2. Deposit IC area protection layer, including: LPCVD silicon oxide 3000 LPCVD silicon nitride 1800 Form a silicon oxide layer 4 and a silicon nitride layer 5 on the entire substrate 1, as shown in Figure 1(a);

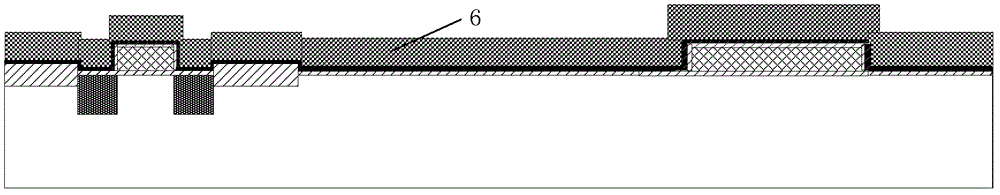

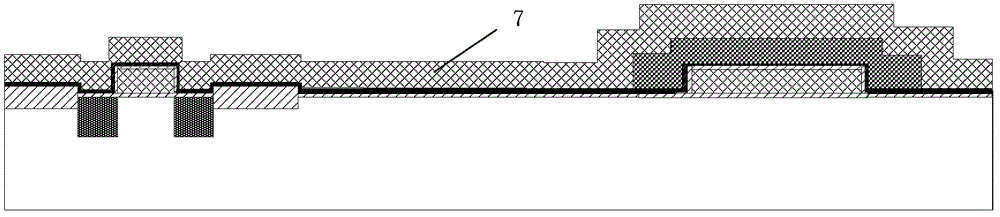

[0042] 3. Use MEMS surface sacrificial layer technology to make movable structures, including:

[0043] a) LPCVD phosphosilicate glass with a thickness of 1 μm, forming a phosphosili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com