Vermicular Sb2Se3 hydrogen storage material and preparation method thereof

A hydrogen storage material and worm-like technology, applied in the field of hydrogen storage materials and preparation, can solve the problems of product purification, high energy consumption, strict equipment requirements, etc., and achieve the effect of simple device, low price and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

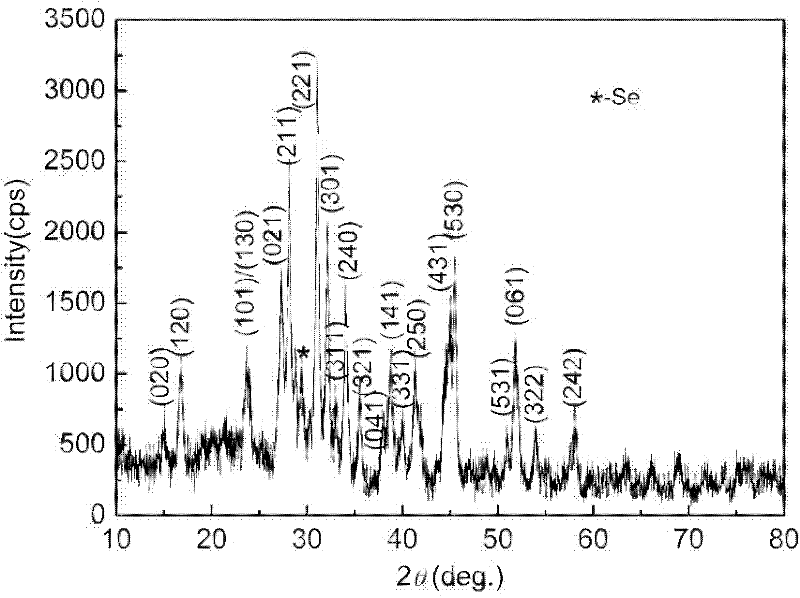

[0015] Specific embodiment 1: This embodiment The worm-like Sb of the present invention 2 Se 3 The hydrogen storage material is made of potassium antimony tartrate (K(SbO)C 4 H 4 O 6 ·0.5H 2 O), sodium selenite (Na 2 SeO 3 ·5H 2 O) Worm-like Sb made by solvothermal synthesis of glucose and mixed solvents 2 Se 3 ; Among them, the molar ratio of potassium antimony tartrate and sodium selenite is 2:2.9~3.1, the mass ratio of potassium antimony tartrate and glucose is 1:1.1~4.5, and the mass-volume ratio of potassium antimony tartrate and mixed solvent is 1g:230~ 250 mL, the mixed solvent is formed by mixing ethylenediamine and ethylene glycol in a volume ratio of 1:2 to 3.

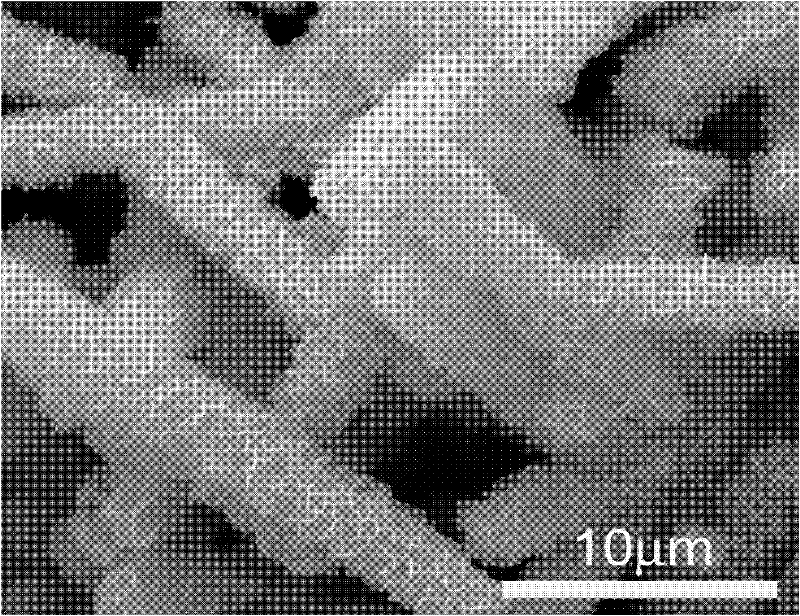

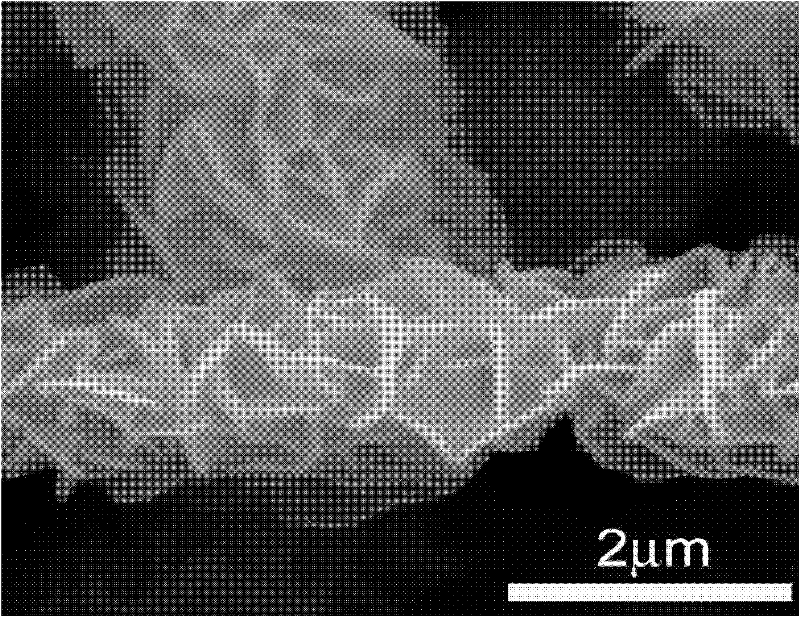

[0016] Worm-shaped Sb of this embodiment 2 Se 3 The preparation method of the hydrogen storage material adopts low raw material price, simple device and simple operation. The worm-like Sb 2 Se 3 The microscopic appearance of the hydrogen storage material is worm-like, with a diameter of 1 to 2 μm and a length of ...

specific Embodiment approach 2

[0017] The second embodiment: the worm-like Sb of this embodiment 2 Se 3 The preparation method of hydrogen storage material is carried out according to the following steps:

[0018] 1. The molar ratio of potassium antimony tartrate to sodium selenite is 2:2.9~3.1, the mass ratio of potassium antimony tartrate to glucose is 1:1.1~4.5, and the mass-volume ratio of potassium antimony tartrate to mixed solvent is 1g:230 Weigh antimony potassium tartrate (K(SbO)C 4 H 4 O 6 ·0.5H 2 O), sodium selenite (Na 2 SeO 3 ·5H 2 O), glucose and mixed solvent are mixed uniformly to obtain a mixed solution; the mixed solvent is made by mixing ethylenediamine and ethylene glycol in a volume ratio of 1:2~3;

[0019] 2. Transfer the mixed solution obtained in step 1 to a reaction kettle, and place it in an oven at a temperature of 140-200°C for 1.5-18 hours;

[0020] 3. Take out the reaction kettle, cool it to room temperature naturally, pour out the product and wash it with absolute ethanol and distill...

specific Embodiment approach 3

[0022] Specific embodiment three: This embodiment is different from specific embodiment two in that in step one, the molar ratio of potassium antimony tartrate to sodium selenite is 2:2.95~3.05, and the mass ratio of potassium antimony tartrate to glucose is 1:1.5~ 3.5. The mass volume ratio of potassium antimony tartrate to the mixed solvent is 1g:235~245mL. Others are the same as the second embodiment.

[0023] In this embodiment, glucose is a surfactant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com