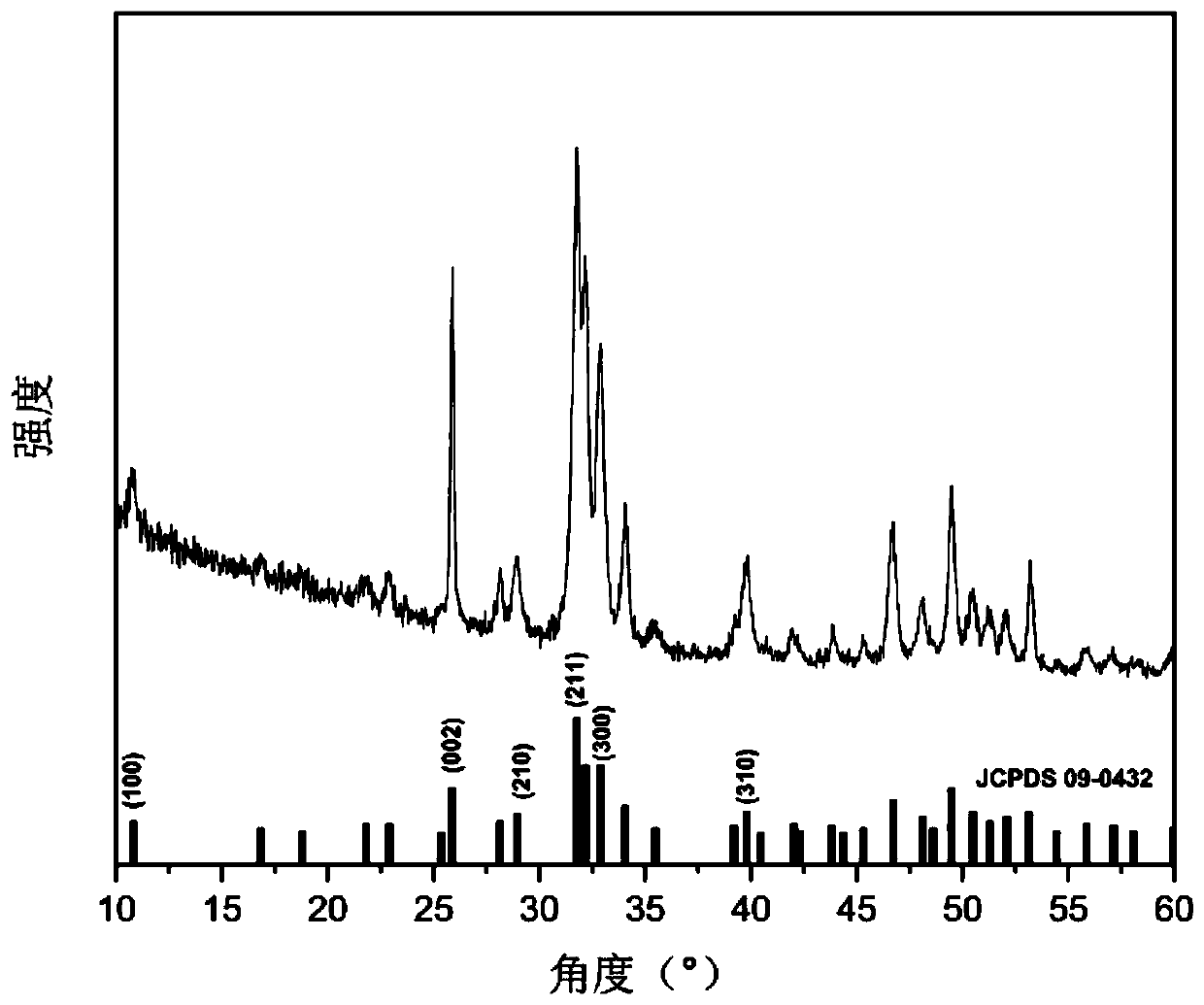

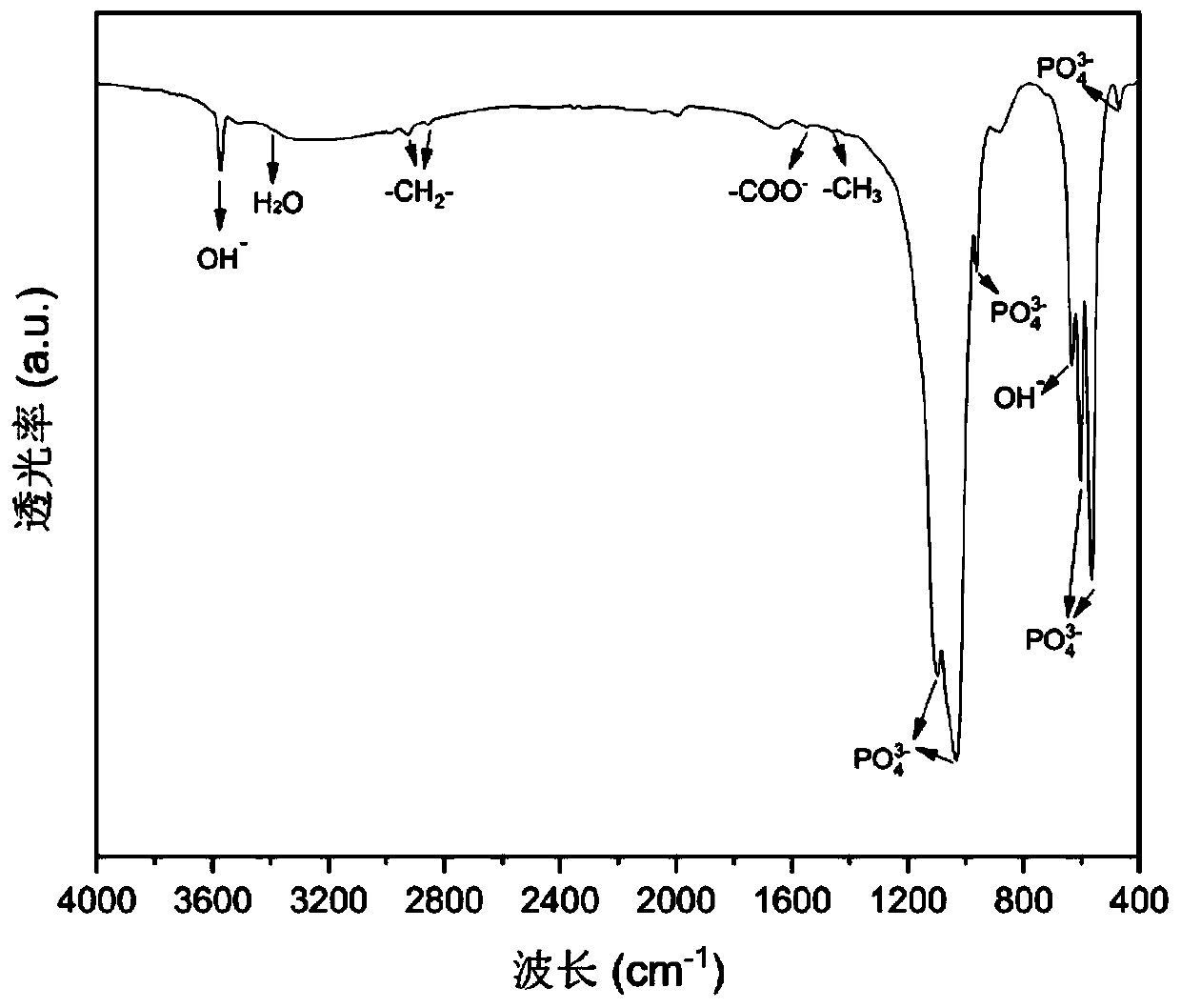

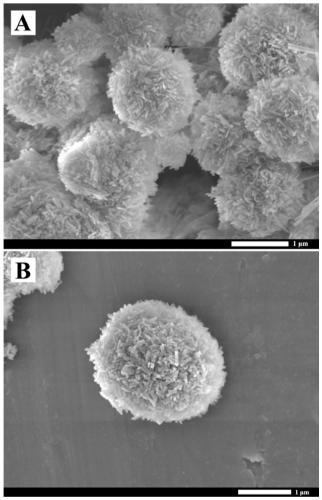

A kind of hydroxyapatite nanocolumn self-assembled microsphere and preparation method thereof

A technology of hydroxyapatite and nanocolumns, which is applied in the field of hydroxyapatite nanocolumn self-assembled microspheres and its preparation, can solve the problems of EDTA not being environmentally friendly, and achieve unique microscopic morphology, broad application prospects, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing hydroxyapatite nanocolumn self-assembled microspheres, comprising the steps of:

[0038]Add 12.00g of stearic acid to 12.00g of ethanol, and dissolve the stearic acid completely at a water bath temperature of 50°C under stirring conditions; add 20ml of 1.00g of sodium hydroxide dropwise at a water bath temperature of 50°C under stirring conditions Aqueous solution, after the addition of sodium hydroxide aqueous solution is completed, the reaction temperature is raised to 65°C; in a water bath at a temperature of 65°C, under stirring conditions, add 20ml of an aqueous solution containing 0.22g of calcium chloride dropwise to form a calcium stearate precursor; cool down to 50°C, add 10ml of an aqueous solution containing 0.2368g of sodium tripolyphosphate dropwise at a water bath temperature of 50°C under stirring conditions, and after the aqueous solution of sodium tripolyphosphate has been added dropwise, transfer the reaction solution to water at ...

Embodiment 2

[0041] A method for preparing hydroxyapatite nanocolumn self-assembled microspheres, comprising the steps of:

[0042] Add 12.00g of stearic acid to 12.00g of ethanol, and dissolve the stearic acid completely at a water bath temperature of 50°C under stirring conditions; add 20ml of 1.00g of sodium hydroxide dropwise at a water bath temperature of 50°C under stirring conditions Aqueous solution, after the addition of sodium hydroxide aqueous solution is completed, the reaction temperature is raised to 65°C; in a water bath at a temperature of 65°C, under stirring conditions, add 20ml of an aqueous solution containing 0.22g of calcium chloride dropwise to form a calcium stearate precursor; cool down to 50°C, add 10ml of an aqueous solution containing 0.2368g of sodium tripolyphosphate dropwise at a water bath temperature of 50°C under stirring conditions, and after the aqueous solution of sodium tripolyphosphate has been added dropwise, transfer the reaction solution to water at...

Embodiment 3

[0044] A method for preparing hydroxyapatite nanocolumn self-assembled microspheres, comprising the steps of:

[0045] Add 12.00g of stearic acid to 12.00g of ethanol, and dissolve the stearic acid completely at a water bath temperature of 50°C under stirring conditions; add 20ml of 1.00g of sodium hydroxide dropwise at a water bath temperature of 50°C under stirring conditions Aqueous solution, after the addition of sodium hydroxide aqueous solution is completed, the reaction temperature is raised to 65°C; in a water bath at a temperature of 65°C, under stirring conditions, add 20ml of an aqueous solution containing 0.22g of calcium chloride dropwise to form a calcium stearate precursor; cool down to 50°C, add 10ml of an aqueous solution containing 0.2368g of sodium tripolyphosphate dropwise at a water bath temperature of 50°C under stirring conditions, and after the aqueous solution of sodium tripolyphosphate has been added dropwise, transfer the reaction solution to water at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com