Treatment process of antibiotic pharmacy waste water

A pharmaceutical wastewater and treatment process technology, which is applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of reducing treatment efficiency, achieve high tolerance, and reduce environmental risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

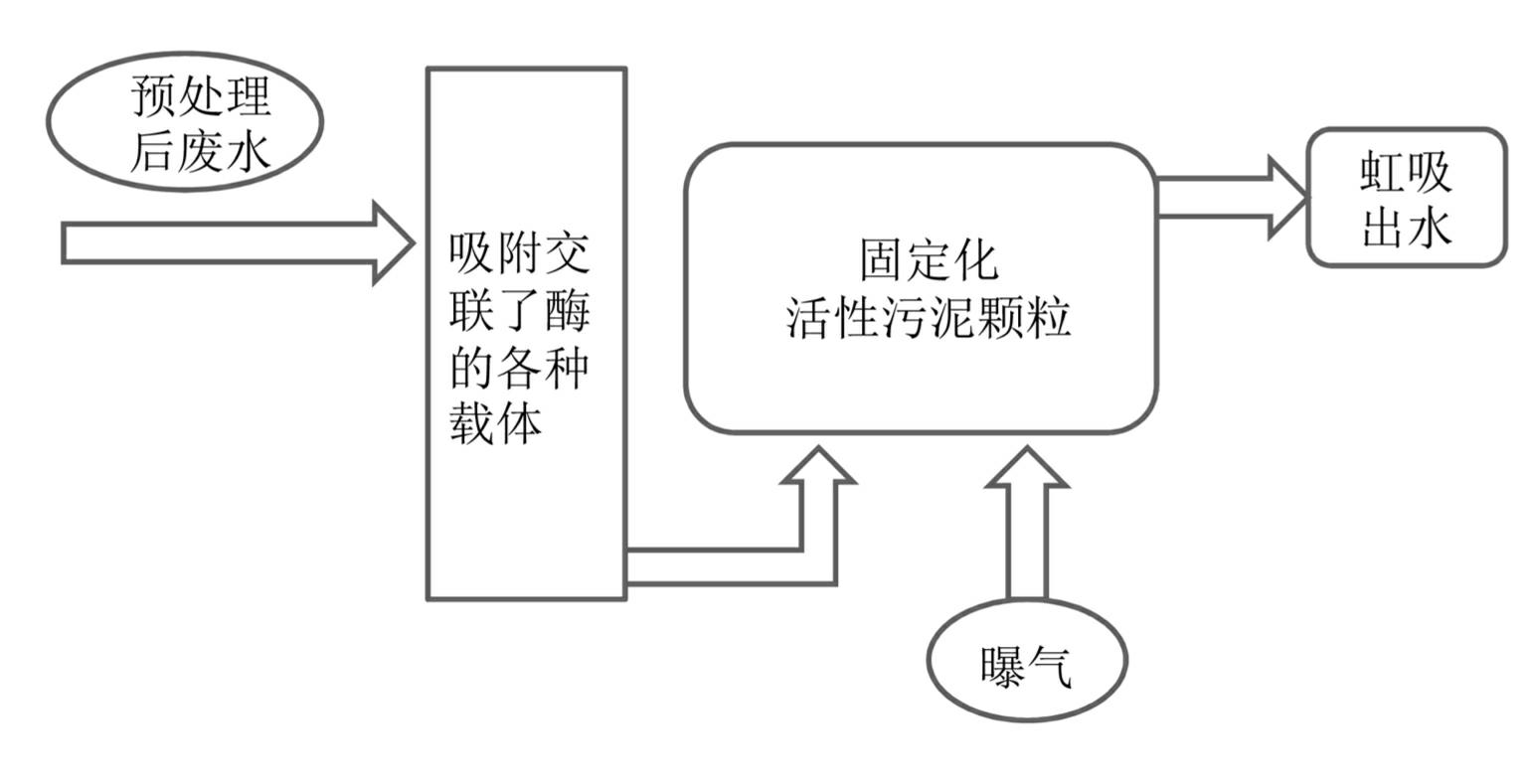

Method used

Image

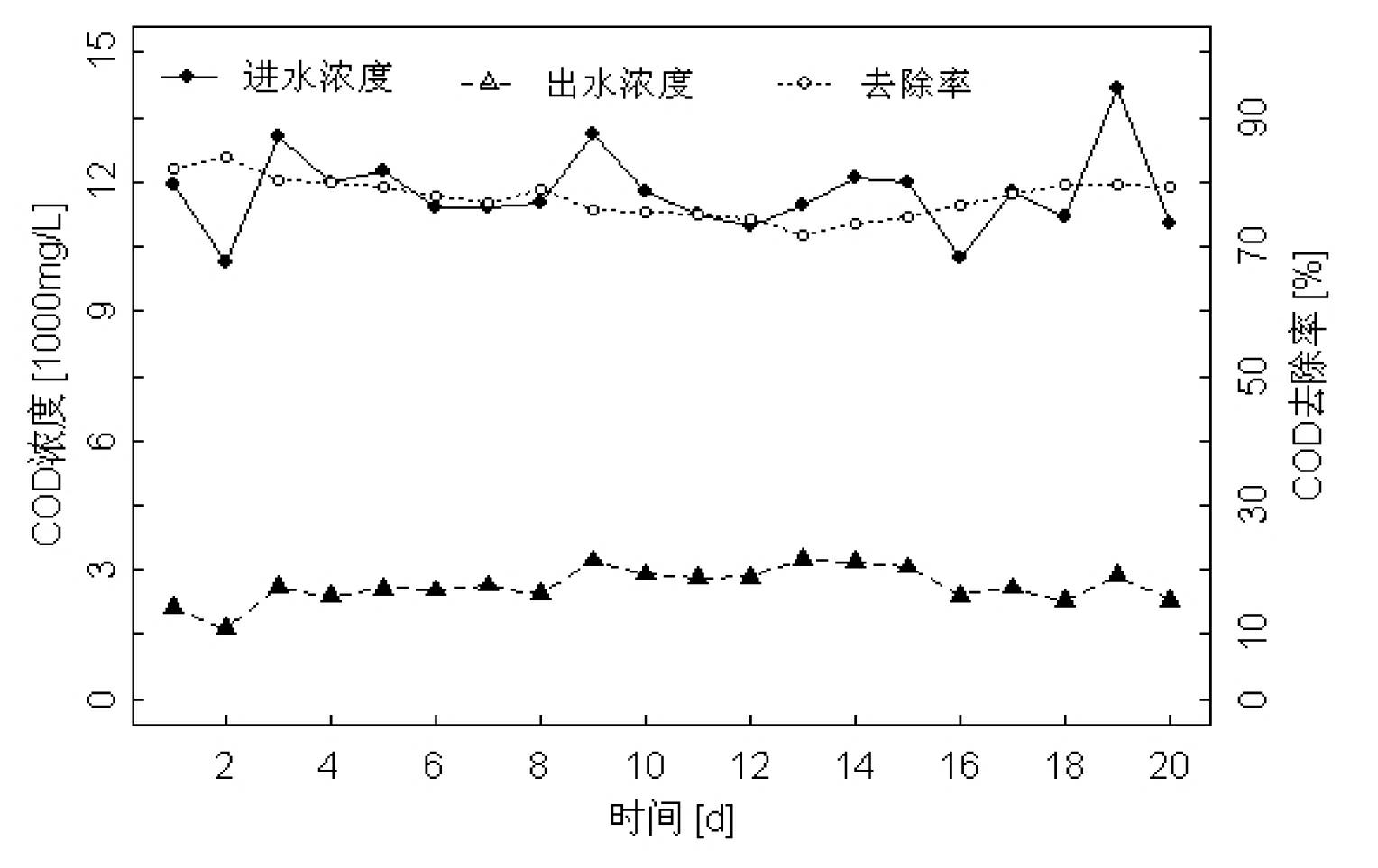

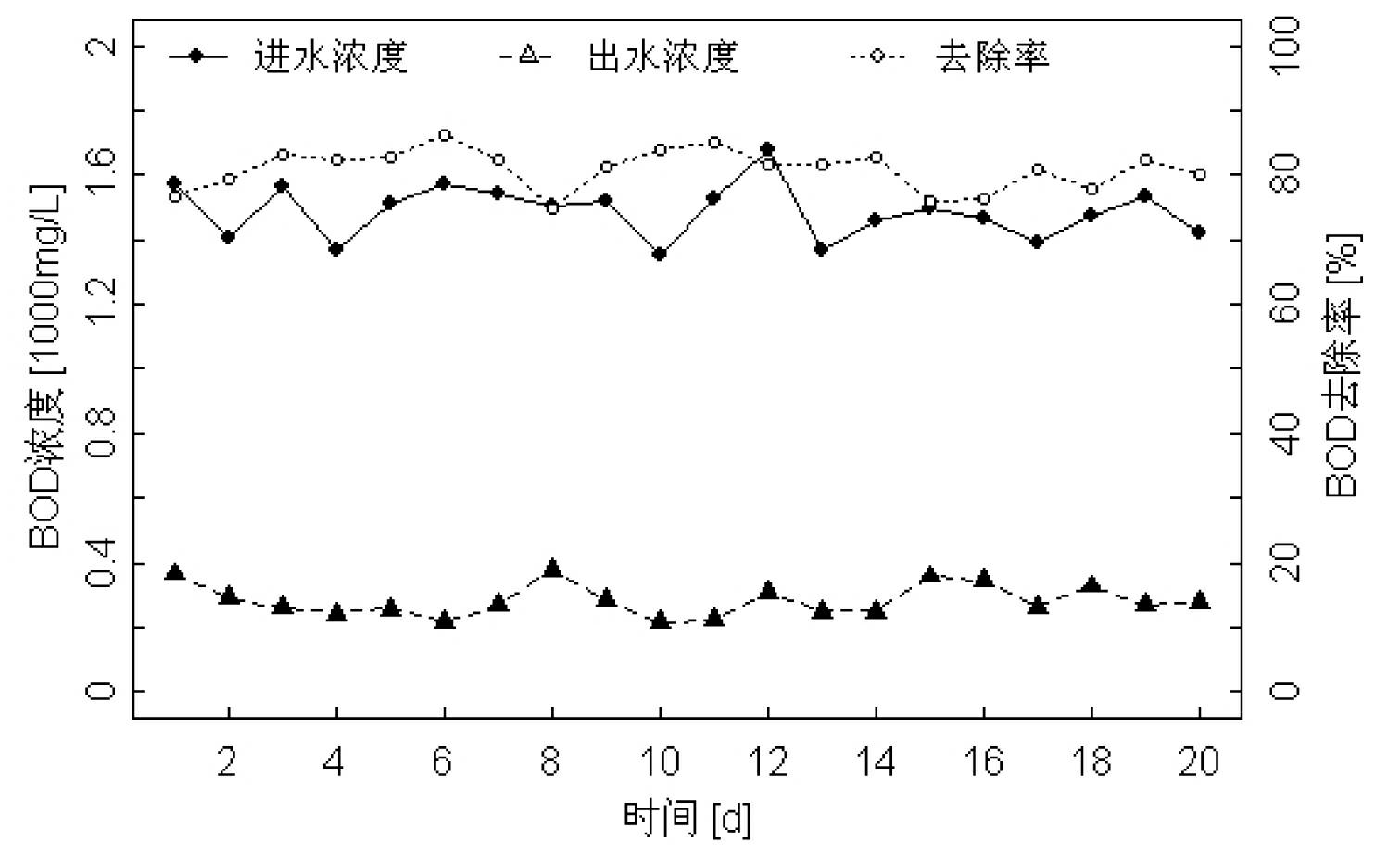

Examples

Embodiment 1

[0037] Example 1 Treatment process for antibiotic pharmaceutical wastewater rich in penicillin and its intermediates

[0038] 1. Preparation of immobilized biological enzyme

[0039] (1) Bacterial cellulose membrane carrier

[0040] Bacterial cellulose membranes were produced by fermentation of Acetobacter xylinum. The bacterial cellulose membrane carrier used in this experiment was directly purchased from Shaanxi Institute of Microbiology.

[0041] (2) Immobilization of biological enzymes

[0042]According to the characteristics of penicillin production wastewater, penicillinase (2 mass parts, enzyme activity 1500 U / mg, pH 6), isopenicillin N synthetase (0.5 mass parts, enzyme activity 800 U / mg, pH 6), acyl-CoA Isopenicillin N acyltransferase (0.5 parts by mass, enzyme activity of 1000 U / mg, pH 6) was used as a complex enzyme system. The enzyme system used was purchased from Suzhou Shengna Biotechnology Co., Ltd. The reconstituted enzyme solution was mixed, concentrated...

Embodiment 2

[0058] Example 2 Treatment process 1 for pharmaceutical wastewater rich in cephalosporin C and its intermediates

[0059] 1. Preparation of immobilized biological enzyme

[0060] (1) Bio-carbon fiber carrier

[0061] The bio-carbon fiber used in this experiment is T300 grade carbon fiber, purchased from Toray Co., Ltd., Japan.

[0062] (2) Immobilization of biological enzymes

[0063] According to the characteristics of penicillin production wastewater, cephalosporin enzyme (2 parts by mass, enzyme activity of 1800 U / mg, pH 6), isopenicillin N synthase (0.5 parts by mass, enzyme activity of 800 U / mg, pH 6), Acetoxycephalosporin C synthetase (0.5 parts by mass, enzyme activity of 1000 U / mg, pH 6), deacetoxycephalosporin C oxygenase (0.5 parts by mass, enzyme activity of 1000 U / mg, pH 6) and Acetyltransferase (0.5 parts by mass, enzyme activity of 1000 U / mg, pH 6) was used as a complex enzyme system. The enzyme system was directly purchased from Suzhou Shengna Biotechnolog...

Embodiment 3

[0078] Example 3 Treatment process 2 for pharmaceutical wastewater rich in cephalosporin C and its intermediates

[0079] 1. Preparation of immobilized biological enzyme

[0080] (1) Bio-carbon fiber carrier

[0081] The carbon fiber used in this experiment is chitosan, with a deacetylation degree of 95%, purchased from Qingdao Yunzhou Biotechnology Mailbox Company.

[0082] (2) Immobilization of biological enzymes

[0083] According to the characteristics of penicillin production wastewater, cephalosporin enzyme (2 parts by mass, enzyme activity of 1800 U / mg, pH 6), isopenicillin N synthase (0.5 parts by mass, enzyme activity of 800 U / mg, pH 6), Acetoxycephalosporin C synthetase (0.5 parts by mass, enzyme activity of 1000 U / mg, pH 6), deacetoxycephalosporin C oxygenase (0.5 parts by mass, enzyme activity of 1000 U / mg, pH 6) and Acetyltransferase (0.5 parts by mass, enzyme activity of 1000 U / mg, pH 6) was used as a complex enzyme system. The enzyme system was directly purc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com