High-ammonia-nitrogen wastewater treatment method

A waste water treatment, high ammonia nitrogen technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve immature process, low TN removal rate, intolerance to impact load, etc. problems, to achieve the effect of ensuring continuity and stability, easy management and maintenance, and high impact load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

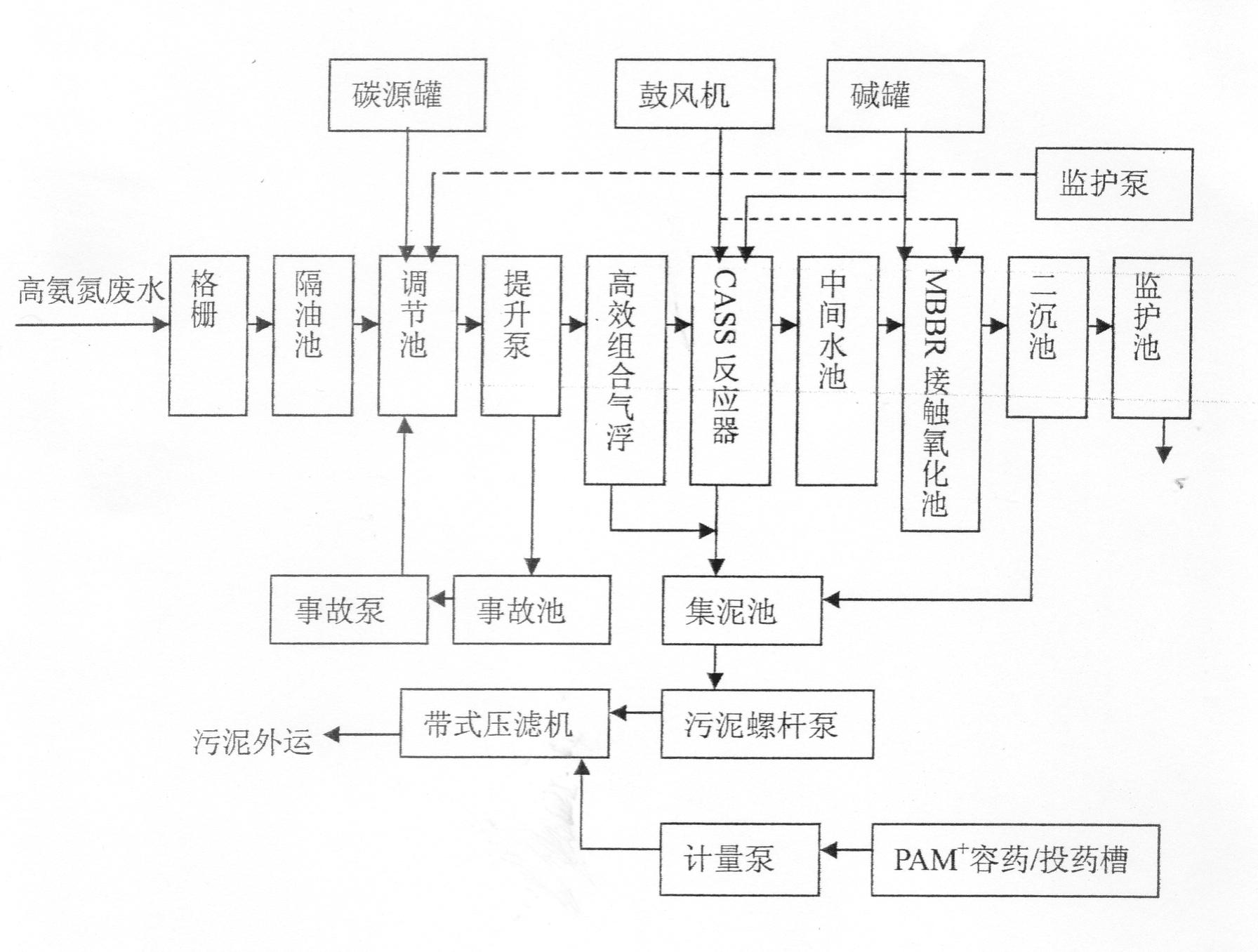

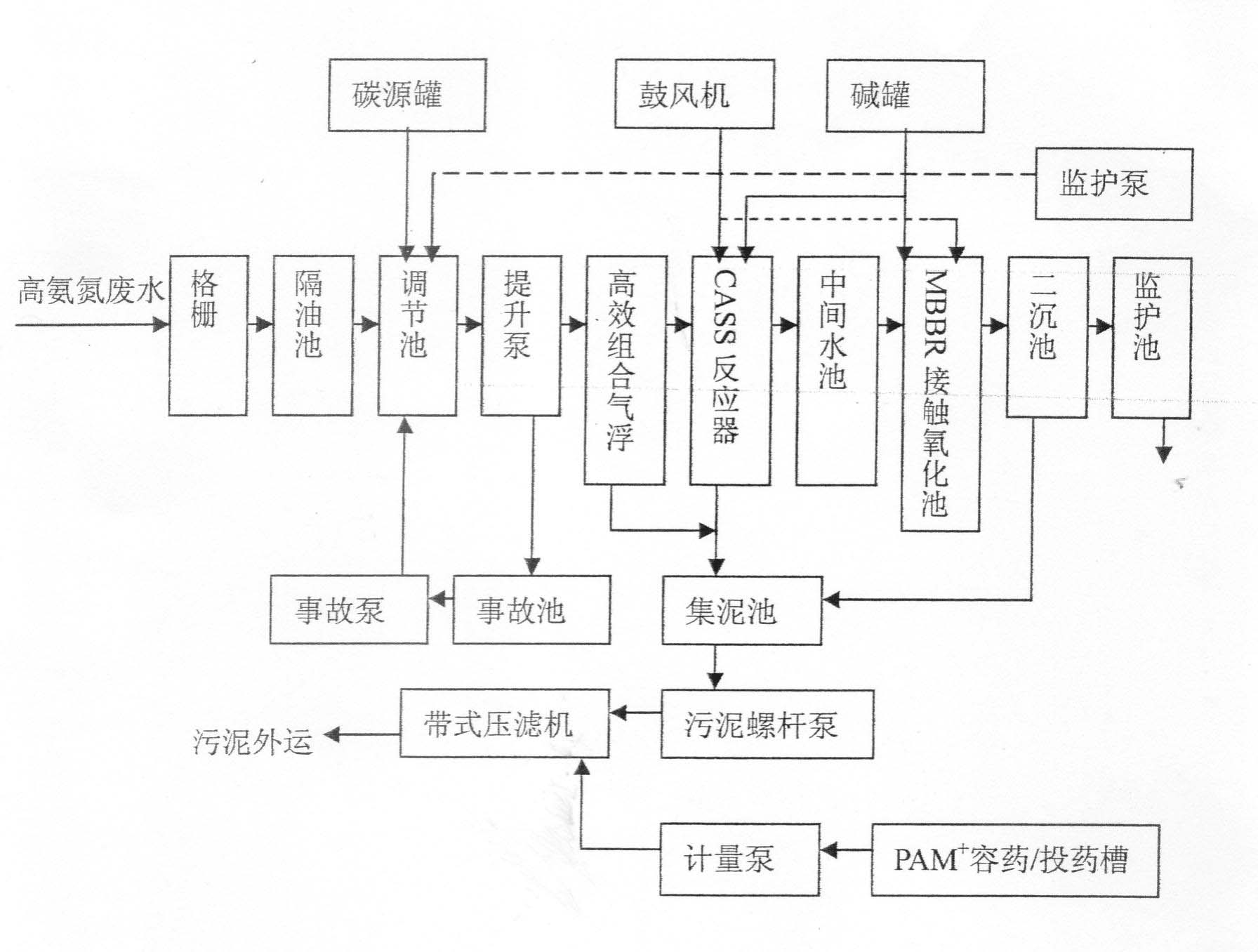

[0008] As shown in the process flow chart, a method for treating high ammonia nitrogen wastewater is composed of a mechanical grid tank, a grease trap, a regulating tank, a carbon source tank, a high-efficiency combined air flotation, a CASS reactor, a Roots blower, and a CASS reflux Pump, intermediate tank, MBBR contact oxidation tank, secondary settling tank, alkali tank, monitoring tank, accident tank, sludge collection tank and sludge filter press system, supplemented by pH, COD, NH 3 -N, liquid level gauge, MLSS, DO, ORP online monitor, the high ammonia nitrogen wastewater under normal production conditions comes from the production wastewater of each process in the production device area, and first flows through the mechanical grid tank to remove large floating objects and larger particles, so as not to affect the subsequent processing equipment; then enter the grease trap for preliminary oil removal, set an oil decanter in the grease trap, and decant the floating oil; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com