Method for preparing methyl phenyl dichlorosilane

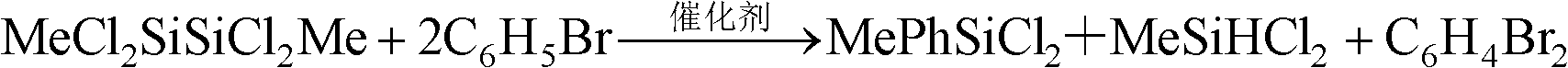

A technology of methylphenyldichlorosilane and dimethyldisilane, which is applied in the field of preparation of methylphenyldichlorosilane, can solve the problems of low yield and difficult PhCl, etc., achieve less side reactions and easy industrialization , easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In a 500 ml three-necked flask equipped with a reflux condenser and a thermometer, add 50 mL of Me 2 ClSiSiCl 2 Me, 100mL bromobenzene, 0.25g Pd(PPh 3 ) 4 , 100mL [Emim]Br+AlCl 3 For ionic liquids, slowly heat up to 150°C, turn on magnetic stirring and reflux for 20 hours to remove MeSiHCl 2 , after the reaction to the product (mainly MePhSiCl 2 and dibromobenzene) to condense, solid-liquid separation to remove solid impurities, to obtain MePhSiCl 2 liquid mixture. The resulting liquid phase mixture is then analyzed by gas chromatography-mass spectrometry (GC-MS), and calculated, the conversion rate of raw material disilane is 71%, and the product MePhSiCl 2 The yield was 54%.

Embodiment 2

[0028] In a 500 ml three-necked flask equipped with a reflux condenser and a thermometer, add 50 mL of Me 2 ClSiSiCl 2 Me, 100mL bromobenzene, 0.25g Pd(PPh 3 ) 4 , 100mL [Bmim]Cl+AlCl 3 For ionic liquids, slowly heat up to 150°C, turn on magnetic stirring and reflux for 20 hours to remove MeSiHCl 2 , after the reaction to the product (mainly MePhSiCl 2 and dibromobenzene) to condense, solid-liquid separation to remove solid impurities, to obtain MePhSiCl 2 liquid mixture. Then the obtained liquid phase mixture is analyzed by GC-MS, and calculated, the conversion rate of raw material disilane is 77%, and the product MePhSiCl 2 The yield is 60%.

Embodiment 3

[0030] In a 500 ml three-necked flask equipped with a reflux condenser and a thermometer, add 50 mL of Me 2 ClSiSiCl 2 Me, 100mL bromobenzene, 0.25g Pd(PPh 3 ) 4 , 100mL [Bmim]PF 6 For ionic liquids, heat up slowly to 120°C, turn on magnetic stirring and reflux for 20 hours to remove MeSiHCl 2 , after the reaction to the product (mainly MePhSiCl 2 and dibromobenzene) to condense, solid-liquid separation to remove solid impurities, to obtain MePhSiCl 2 liquid mixture. Then the obtained liquid phase mixture is analyzed by GC-MS, calculated, the raw material disilane conversion rate is 83%, and the product MePhSiCl 2 The yield was 73%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com