Halogen-free and flame-retardant hard polyurethane foam plastic and preparation method thereof

A technology of rigid polyurethane and foamed plastics, which is applied in the field of foamed plastics, can solve problems not related to the flame retardancy of rigid polyurethane foamed plastics, and achieve the effects of good flame retardancy, excellent heat preservation and wide application range of phosphorus, nitrogen and silicon synergistically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

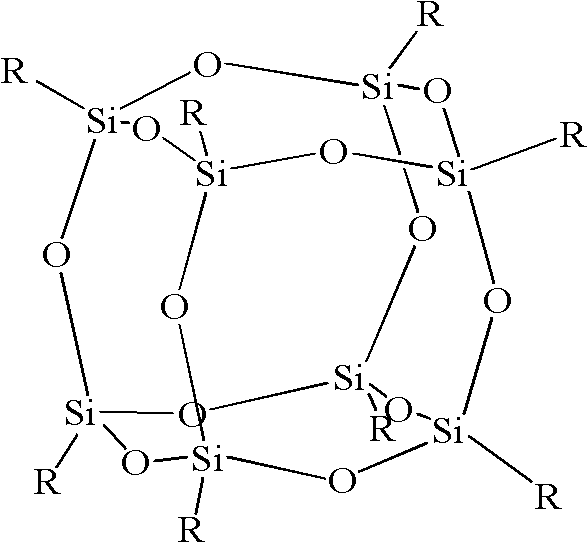

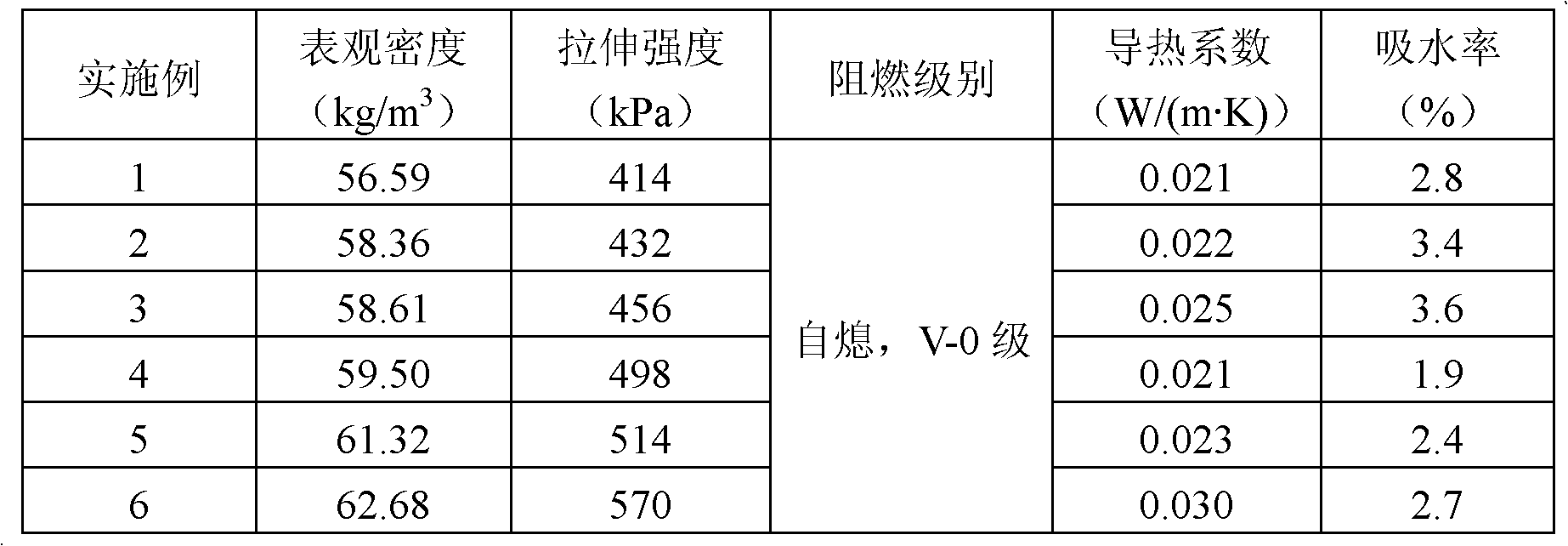

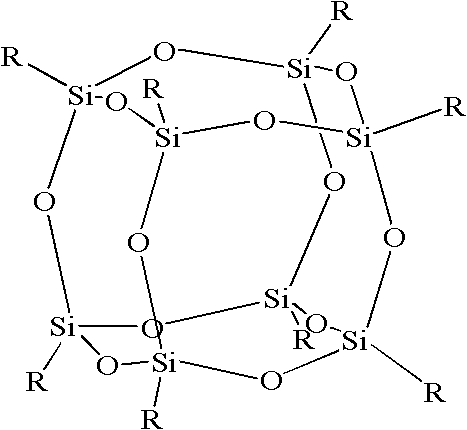

[0041] Weigh 100g polyether polyol 4110, 1.0g tertiary amine catalyst and 0.02g dibutyltin dilaurate, 1g silicon-carbon bond type foam stabilizer, 1g2,4,6-tris(dimethylaminomethyl)phenol, 0.1 g water and 0.2g cyclopentane, 25g micron grade α-alumina trihydrate, 0.05g octa(3-hydroxy-3-methylbutyldimethylsiloxy)silsesquioxane with a high-speed stirrer at room temperature Mix evenly under 2500r / min high-speed stirring. Add 20g of dimethyl methylphosphonate and mix evenly, then quickly add 120g of polymethylene polyphenylisocyanate, stir at room temperature at 2500r / min at high speed and mix evenly. When the mixture is observed to be whitish, it is poured into a self-made mold to foam freely, after foaming, it is aged for 48 hours, and the rigid polyurethane foam is obtained after demoulding.

Embodiment 2

[0043]Weigh 100g polyether polyol 4110, 1.5g tertiary amine catalyst and 0.04g dibutyltin dilaurate, 1g silicon-carbon bond type foam stabilizer, 1g2,4,6-tris(dimethylaminomethyl)phenol, 0.2 g water and 0.4 g cyclopentane, 25 g micron-sized α-alumina trihydrate, 0.06 g octa(3-hydroxy-3-methylbutyldimethylsiloxy) silsesquioxane with a high-speed stirrer at room temperature Mix evenly under 2500r / min high-speed stirring. Add 25g of dimethyl methylphosphonate and mix evenly, then quickly add 120g of polymethylene polyphenylisocyanate, stir at room temperature at 2500r / min at a high speed and mix evenly. When the mixture is observed to be whitish, it is poured into a self-made mold to foam freely, after foaming, it is aged for 48 hours, and the rigid polyurethane foam is obtained after demoulding.

Embodiment 3

[0045] Weigh 100g polyether polyol 4110, 1.5g tertiary amine catalyst and 0.04g dibutyltin dilaurate, 1.5g silicon-carbon bond type foam stabilizer, 1.5g2,4,6-tris(dimethylaminomethyl)phenol , 0.3g water and 0.6g cyclopentane, 25g micron grade α-alumina trihydrate, 0.07g octa(3-hydroxy-3-methylbutyldimethylsiloxy)silsesquioxane with a high-speed mixer Mix evenly under 2500r / min high-speed stirring at room temperature. Add 30g of dimethyl methylphosphonate and mix evenly, then quickly add 120g of polymethylene polyphenylisocyanate, stir at room temperature at 2500r / min at high speed and mix evenly. When the mixture is observed to be whitish, it is poured into a self-made mold to foam freely, after foaming, it is aged for 48 hours, and the rigid polyurethane foam is obtained after demoulding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com