Continuous fiber reinforcement polybutylene terephthalate material and preparation method

A technology of polybutylene terephthalate and continuous fiber, which is applied in the field of continuous fiber reinforced polybutylene terephthalate material and its preparation, can solve the problems of decreased impact toughness and failure to achieve it, and achieve improvement The effect of rigidity and strength, high production efficiency, and excellent hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

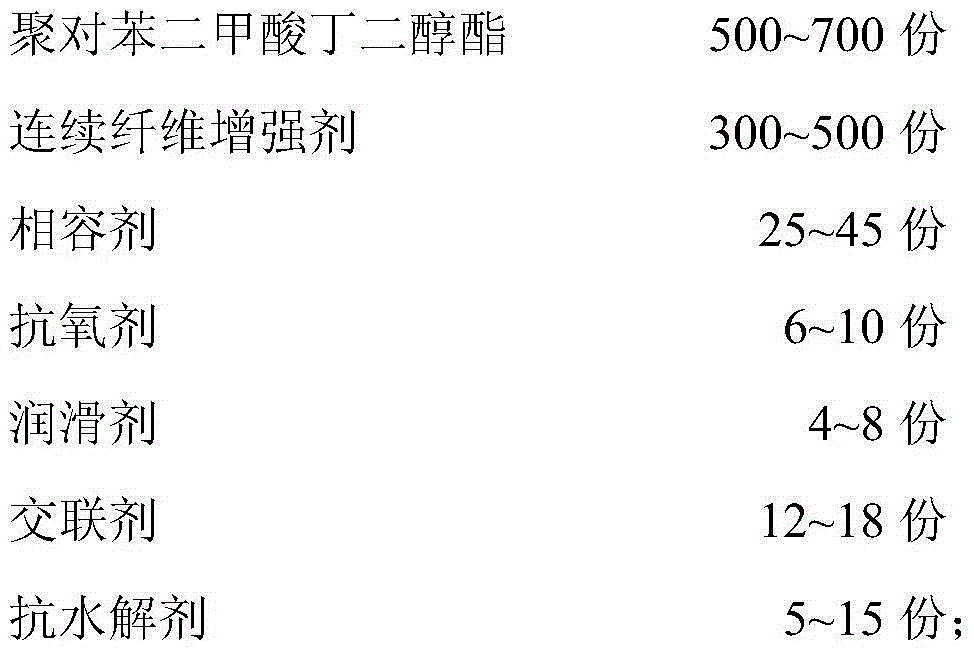

[0041] The invention provides a high-strength, high-toughness, hydrolysis-resistant continuous fiber-reinforced polybutylene terephthalate material (hereinafter referred to as high-resistance material), the cutting length of the material is 11-13 mm, and the particle size is 2.0-4.0 mm.

[0042] (1) Drying preparation: put the polybutylene terephthalate raw material in a dryer, drying temperature: 95°C; drying time: 8h;

[0043] (2) Mixing preparation; 700 parts of polybutylene terephthalate, 35 parts of compatibilizer ethylene-acrylate-glycidyl methacrylate (GMA), 9 parts of antioxidant, wherein antioxidant The weight ratio of agent 1010 to antioxidant 168 is 1:2, 5 parts of lubricant ethylene-acrylic acid copolymer wax (AC540A), 15 parts of crosslinking agent triglycidyl isocyanurate, 8 parts of antihydrolysis agent high molecular weight Add polycarbodiimide to the high-speed mixer in turn, control the mixing temperature at 55°C, stop the mixing time after 4 minutes, and then ...

Embodiment 2

[0050] The high resistance material is prepared by the following method, which includes the following steps:

[0051] (1) Drying preparation: put the polybutylene terephthalate raw material in a dryer, drying temperature: 95°C; drying time: 8h;

[0052] (2) Mixing preparation; 600 parts of polybutylene terephthalate, 35 parts of compatibilizer ethylene-acrylate-glycidyl methacrylate (GMA), 9 parts of antioxidant, wherein antioxidant The weight ratio of agent 1010 to antioxidant 168 is 1:2, 5 parts of lubricant ethylene-acrylic acid copolymer wax (AC540A), 15 parts of crosslinking agent triglycidyl isocyanurate (TGIC), 8 parts of antihydrolysis agent Add high molecular weight polycarbodiimide (Stabaxol P) into the high mixer one by one, control the mixing temperature at 55°C, stop the mixing time after 4min, and then add the mixed material into the hopper of the extruder For standby, the drying temperature of the extruder hopper is set to 85°C;

[0053] (3) Preparation of hig...

Embodiment 3

[0059] The high resistance material is prepared by the following method, which includes the following steps:

[0060] (1) Drying preparation: put the polybutylene terephthalate raw material in a dryer, drying temperature: 95°C; drying time: 8h;

[0061] (2) Mixing preparation; 500 parts of polybutylene terephthalate, 35 parts of compatibilizer ethylene-acrylate-glycidyl methacrylate (GMA), 9 parts of antioxidant, wherein antioxidant The weight ratio of agent 1010 to antioxidant 168 is 1:2, 5 parts of lubricant ethylene-acrylic acid copolymer wax (AC540A), 15 parts of crosslinking agent triglycidyl isocyanurate (TGIC), 8 parts of antihydrolysis agent It is high molecular weight polycarbodiimide (Stabaxol P), which is added to the high mixer in sequence, the mixing temperature is controlled at 55°C, the mixing time is stopped after 4min, and then the mixed material is added to the hopper of the extruder Standby, the drying temperature of the extruder hopper is set to 85 °C;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com