Method for preparing melanin and precursors thereof by utilizing complex enzyme

A precursor substance, melanin technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of non-reusable, high cost, single enzyme, etc., to improve production efficiency, high production efficiency, High enzymatic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

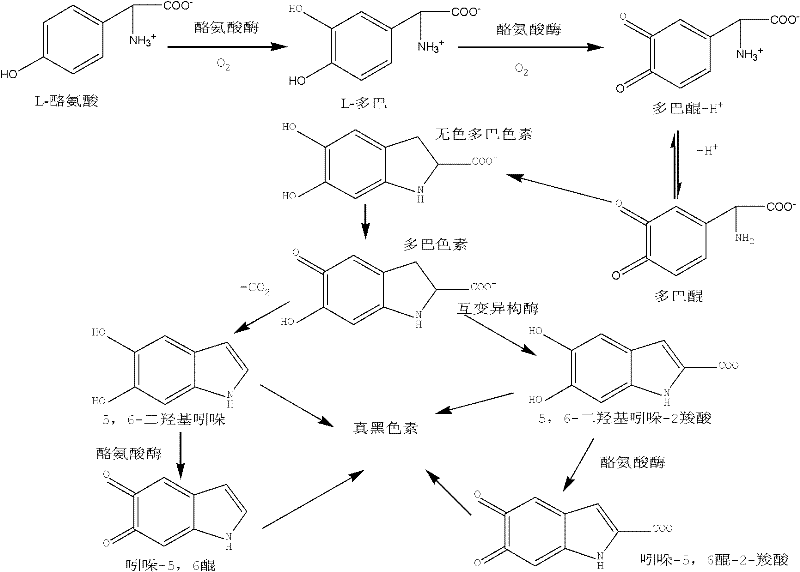

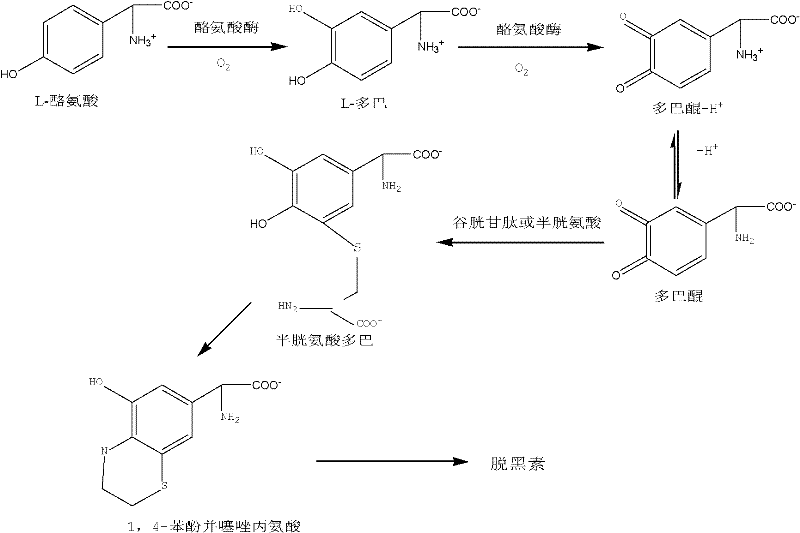

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 melanin precursor substance

[0028] 1) Liquid seed culture: put 50ml of seed medium in a 250ml Erlenmeyer flask, 5g of beef extract, 10g of peptone, 10g of NaCl, 1L of distilled water, pH 7.0, and steam sterilize at 121°C for 20min. Insert Bacillus Subtilis PMR02, the preservation number is CGMCC No.5640, place it on a constant temperature shaker with a rotation speed of 140r / min, cultivate it at 37°C for 8-12 hours, and inoculate it into the fermentation medium when the OD value at 630nm is 0.8 .

[0029] 2) Liquid fermentation culture: put 50ml fermentation medium in a 300ml Erlenmeyer flask, glucose 1.2g, (NH 4 ) 2 SO 4 1.3g, K 2 HPO 4 1g, CaCO 3 3g, MgSO 40.56g, distilled water to 1L, steam sterilized at 121°C for 20min, inoculated according to 4% inoculum size, controlled culture temperature at 37°C, shaker speed at 140r / min, fermented for 18h, took out the fermentation broth, centrifuged at 3000rpm for 15min, took out Th...

Embodiment 2

[0034] The preparation of embodiment 2 melanin precursor material

[0035] 1) Liquid seed culture: put 50ml of seed medium in a 250ml Erlenmeyer flask, 5g of beef extract, 10g of peptone, 10g of NaCl, 1L of distilled water, pH 7.0, and steam sterilize at 121°C for 20min. Insert Bacillus Subtilis PMR02, the preservation number is CGMCC No.5640, place it on a constant temperature shaker with a rotation speed of 140r / min, cultivate it at 37°C for 8-12 hours, and inoculate it into the fermentation medium when the OD value at 630nm is 0.8 .

[0036] 2) Liquid fermentation culture: put 50ml fermentation medium in a 300ml Erlenmeyer flask, glucose 1.2g, (NH 4 ) 2 SO 4 1.3g, K 2 HPO 4 1g, CaCO 3 3g, MgSO 4 0.56g, distilled water to 1L, steam sterilized at 121°C for 20min, inoculated according to 4% inoculum size, controlled culture temperature at 37°C, shaker speed at 140r / min, fermented for 18h, took out the fermentation broth, centrifuged at 3000rpm for 15min, took out S...

Embodiment 3

[0041] The preparation of embodiment 3 melanin precursor material

[0042] 1) Liquid seed culture: put 50ml of seed medium in a 250ml Erlenmeyer flask, 200g of potatoes, 20g of glucose (or sucrose), 1000ml of distilled water, natural pH, steam sterilization at 121°C for 20min. Insert Bacillus Subtilis PMR02, the preservation number is CGMCC No.5640, place it on a constant temperature shaker with a rotation speed of 140r / min, cultivate it at 37°C for 8-12 hours, and inoculate it into the fermentation medium when the OD value at 630nm is 0.8 .

[0043] 2) Liquid fermentation culture: put 50ml of fermentation medium in a 300ml Erlenmeyer flask, 200g of potatoes, 20g of glucose (or sucrose), 1000ml of distilled water, natural pH, steam sterilization at 121°C for 20min, inoculate with 5% inoculum, and control the culture The temperature was 37°C, the rotation speed of the shaker was 140r / min, and the fermentation broth was taken out after 18 hours of fermentation, centrifuged at 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com